Druckguss in der Automobilindustrie

MNW bietet maßgeschneiderte Dienstleistungen zur Herstellung von Automobilteilen für die Produktentwicklung in der Automobilindustrie. Wir bieten verschiedene Spritzguss-, CNC- und Druckgussverfahren für Autoteile an. Das On-Demand-Produktionsmodell des Unternehmens erfüllt die individuellen Bedürfnisse der Kunden.

- Fortschrittliche Verarbeitungsgeräte und Prüfeinrichtungen

- Erfahrener Hersteller von Autoteilen

- 24/7 technische Unterstützung, Kundendienst

On-Demand-Produktion

Fertigungskapazitäten für die Automobilindustrie

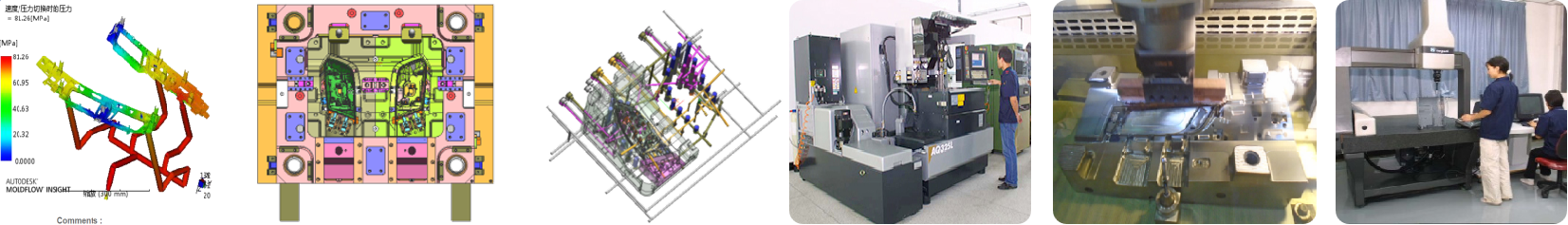

Das technische Team unseres Unternehmens und die fortschrittliche Verarbeitungs- und Prüfausrüstung waren schon immer führend in der Branche. Wir bei MINDWELL haben umfangreiche Erfahrung in der Herstellung von Automobilteilen. Wir sind mit dem Entwicklungsprozess und der Marktnachfrage für Automobilprodukte vertraut.

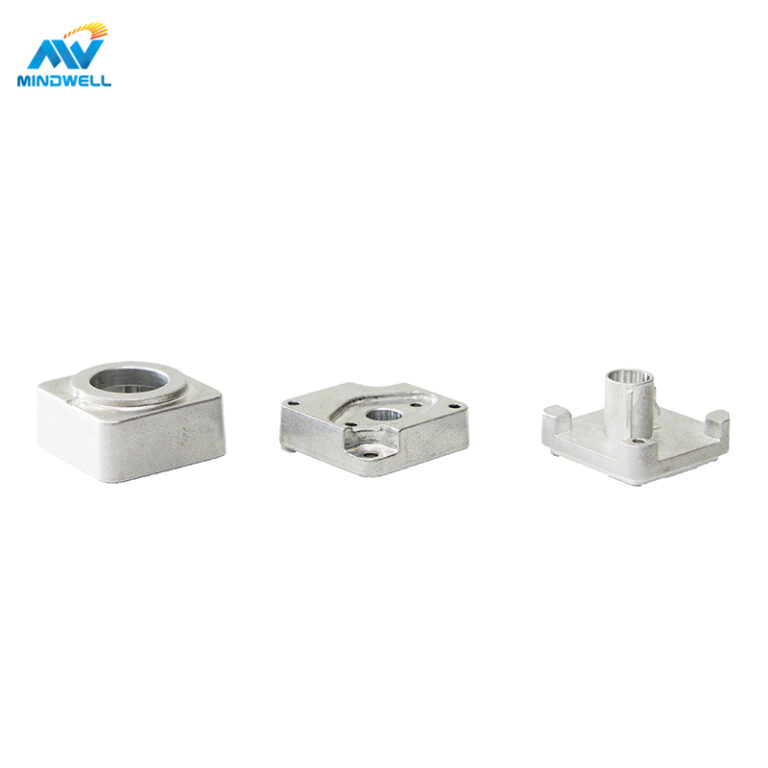

Druckgießen

Unser Druckgussverfahren für Autoteile ist in der Lage, komplexere und präzisere Autoteile mit hoher Maßgenauigkeit, hoher Oberflächengüte und mechanischen Eigenschaften herzustellen. Der Druckguss von Autoteilen wird in der Automobilindustrie häufig zur Herstellung von Motorblöcken, Vergasern, Getriebegehäusen, Halterungen und anderen kritischen Komponenten verwendet, die hohe Festigkeit, Haltbarkeit und Leistung erfordern.

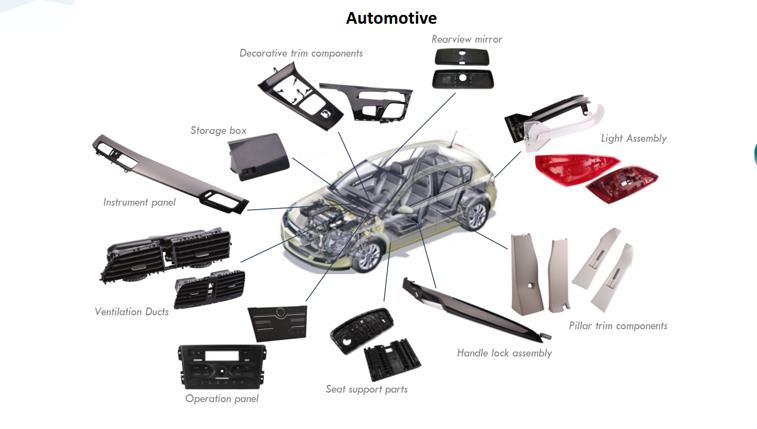

Spritzgießen

Der Automobilspritzguss ist in der Automobilindustrie weit verbreitet, da er hochwertige Teile mit gleichbleibender Qualität und geringem Ausschuss produziert. Unser Unternehmen stellt Automobilteile wie Innen- und Außenverkleidungen, Gehäuse und andere Komponenten her. Bei MindWell bieten wir unseren Kunden die Möglichkeit, komplexe Formen und Designs mit hoher Präzision und Konsistenz herzustellen.

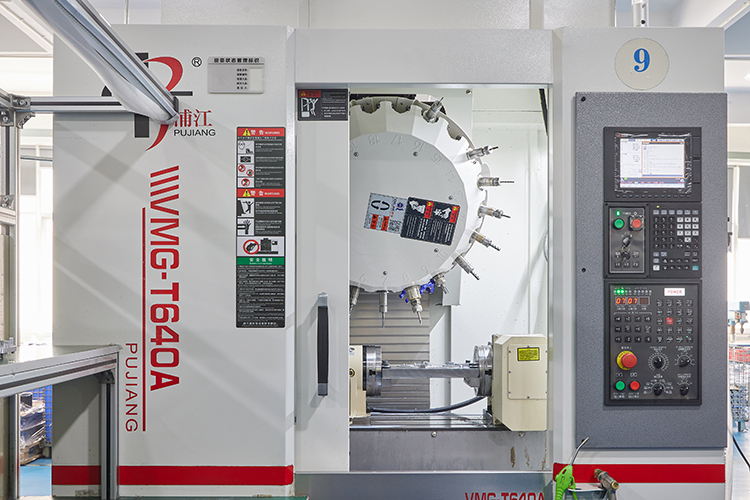

CNC-Bearbeitung

Die CNC-Bearbeitung kann Teile mit hoher Präzision und hoher Effizienz bearbeiten, insbesondere bei komplexen Formen und schwierigen Teilen kann die CNC-Bearbeitung diese Anforderungen erfüllen. Unser Unternehmen verfügt über 4-Achsen-CNC-Bearbeitungsanlagen, die hochpräzise und hocheffiziente Teile bearbeiten können. Die Bearbeitung gewährleistet die Qualität und Präzision der Teile. Die CNC-Bearbeitung kann auch die Produktionseffizienz verbessern und die Kosten senken, weshalb sie von immer mehr Automobilherstellern eingesetzt wird.

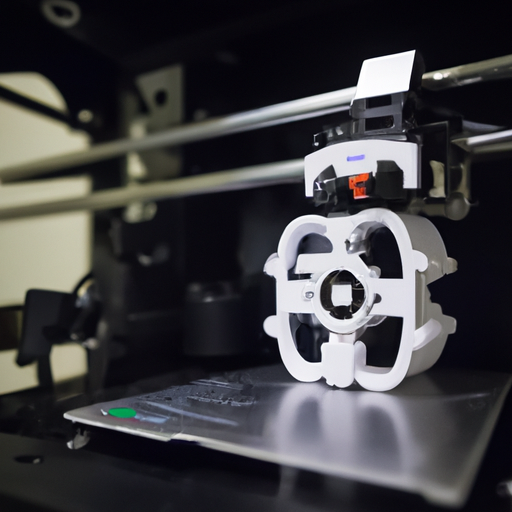

3D-Druck

Wenn Kunden einiger Automobilprodukte schneller Teile erhalten möchten, empfehlen wir ihnen, sich für Autoteile aus dem 3D-Druck zu entscheiden, denn mit der 3D-Drucktechnologie lassen sich schnell hochwertige und präzise Autoteile herstellen. Ein Autoteil kann in wenigen Stunden hergestellt werden. Aber der 3D-Druck stellt strenge Anforderungen an die Anzahl und die Art der produzierten Autoteile, und die Festigkeit und Haltbarkeit der Materialien kann ebenfalls begrenzt sein.

Gussteile für Automobile Hersteller: Mindwell

Als ein Hersteller von Gussteilen für die AutomobilindustrieMNW bietet maßgeschneiderte Lösungen für Autoteile. Unser Unternehmen verfügt über eine Druckgussfabrik, eine Spritzgussfabrik, ein CNC-Bearbeitungszentrum und eine 3D-Drucktechnologie, die Ihre Produktionsanforderungen erfüllen können.

Automobil-Spritzgießen

Spritzgussteile für Automobile Automobile zeichnen sich durch geringes Gewicht, komplexe Formgebung, Korrosionsbeständigkeit und Haltbarkeit aus. Wir bieten unseren Kunden eine gute Designfreiheit und Produktionseffizienz. Weit verbreitet in Innen- und Außenteilen von Autos, wie Armaturenbrettern, Türverkleidungen, Scheinwerfern, Rückleuchten, Sitzen, Lenkrädern und Ersatzteilen.

Automobil-Druckguss

Autoteile Druckguss bezieht sich auf Gussteile für Autoteile, die im Druckgussverfahren hergestellt werden. Druckgussteile, die im Druckgussverfahren hergestellt werden, zeichnen sich durch hohe Präzision, hohe Qualität, hohe Festigkeit, hohe Verschleißfestigkeit und hohe Dichte aus. Weit verbreitet in Automotoren, Getrieben, Aufhängungssystemen, Lenksystemen, Bremssystemen und anderen Komponenten

Starten Sie jetzt mit der individuellen Automobilfertigung nach Ihren Bedürfnissen!

Die richtigen Materialien für die Produktentwicklung in der Automobilindustrie

Die Werkstoffe für die Herstellung von Autoteilen werden in metallische Werkstoffe, nichtmetallische Werkstoffe und Verbundwerkstoffe unterteilt. Die Arten von Autos für verschiedene Zwecke und die Materialien für verschiedene Teile sind unterschiedlich. Unser Unternehmen kann alle Arten von Autoteilen, die Sie wollen, anpassen.

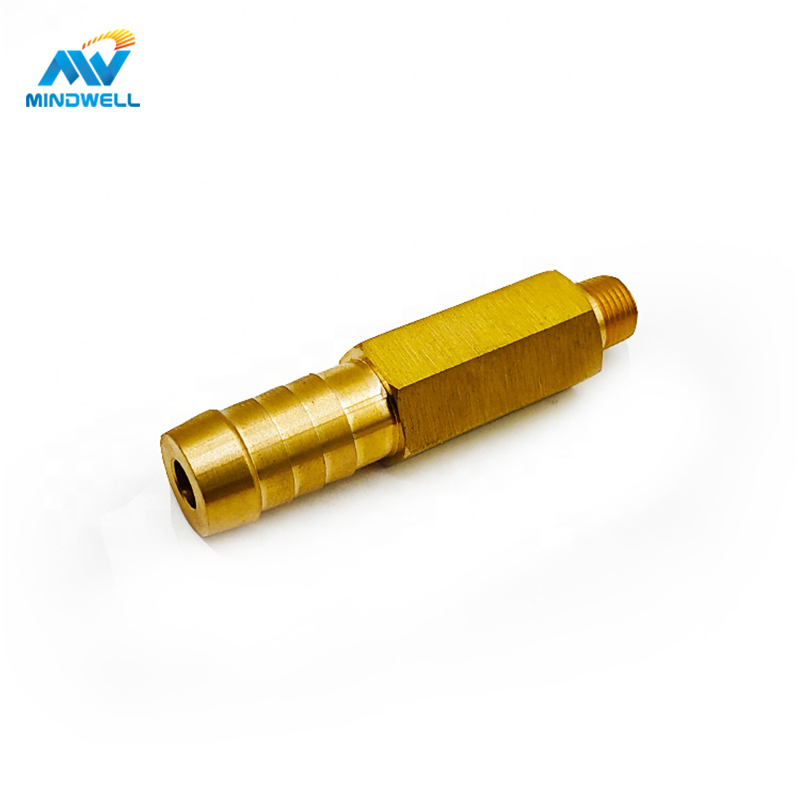

Kupfer

Ob es sich um ein Fahrzeug mit herkömmlichem Kraftstoff oder um ein Fahrzeug mit neuer Energie handelt, Kupferlegierungen sind das wichtigste Ausgangsmaterial für wichtige Komponenten. Hochleistungswerkstoffe aus Kupferlegierungen werden in Kühlsystemen, elektronischen Leistungssystemen, Bremssystemen und Hydrauliksystemen von Kraftfahrzeugen in großem Umfang verwendet.

Magnesium

Im Automobilbau werden Magnesiumlegierungen hauptsächlich für die Karosserie, den Motor, das Fahrgestell und andere Komponenten verwendet. Zum Beispiel werden Magnesiumlegierungen in der Karosseriestruktur einiger High-End-Autos verwendet, die das Gewicht der Karosserie effizient reduzieren und die Handhabung und den Kraftstoffverbrauch des Fahrzeugs verbessern können.

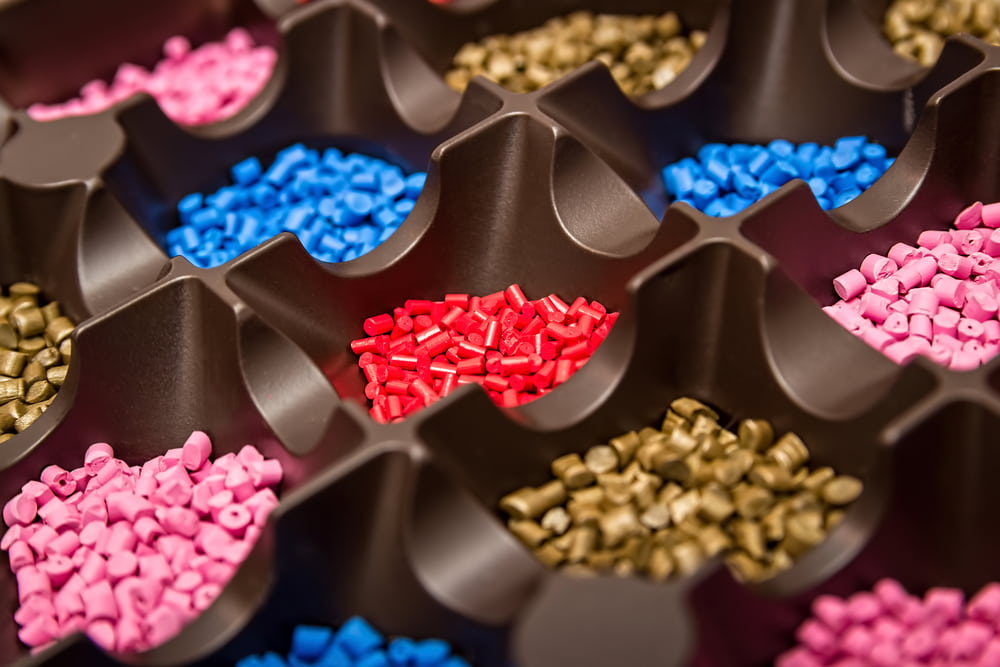

Thermoplastische Kunststoffe

Kunststoffe werden in Automobilen verwendet, z. B. in Motorhauben, Kühlgebläsen, Wassertanks, Kühlergrills usw. Kunststoffe in Automobilen senken nicht nur die Kosten für die Verarbeitung, Montage und Wartung der Teile, sondern machen das Auto auch leichter, energiesparender und umweltfreundlicher.

Gummi

Gummiteile für Automobile sind alle auf wichtige Teile, wie den Motor, Getriebe, Achse und andere Teile des Autos müssen Öldichtungen, aber die kleinen Gummi-Öldichtung ist der Schlüssel, um den normalen Betrieb dieser Teile zu gewährleisten, und schützen die Sicherheit und Haltbarkeit des Autos

Oberflächenveredelung im Automobilbau

Die Oberflächenbehandlung von Autoteilen kann die Ästhetik und die Oberflächenhärte der Teile verbessern und den Verschleiß und die Korrosion der Teile verhindern. Wir empfehlen die Anwendung verschiedener Oberflächenbehandlungsmethoden für unterschiedliche Teile und Umgebungen.

Für die Mittelkonsole des Fahrzeugs empfehlen wir beispielsweise die Verwendung von Chrom/Kies. Die wichtigsten Bearbeitungsmethoden sind im Folgenden aufgeführt:

- Beschichtung

- Sprühen

- Wärmebehandlung

- Poliert

- Ablage

Verwandte Produkte für die Automobilindustrie

MindWell verfügt über langjährige Erfahrung auf dem Gebiet der Verarbeitung von Autoteilen. Die Autoteile, die wir produzieren, sind in verschiedenen Marken der Autoindustrie weit verbreitet.

Druckguss Automobilteile Anwendung

Wir bieten Verarbeitung und Herstellung von Automobil-Spritzgussteilen, Automobil-Druckgussteilen und Automobil-CNC-Bearbeitungsteilen. Bei MindWell haben wir Erfahrung in der Herstellung verschiedener Autoteile. Die üblichen Anwendungen im Automobilbereich, die wir übernehmen, sind in der Abbildung dargestellt

Herstellung von Druckgussteilen nach Kundenwunsch durch Druckguss. Die wichtigsten Materialien sind Aluminium- und Zinklegierungen. Die wichtigsten Oberflächenbehandlungsmethoden sind Chrom/Spray/Sandstrahlen

- Unterstützung hinten

- Car key

- Center console

- engine parts

- Other

Automotive injection molded parts have important structural functions that can increase body strength, improve vehicle performance and improve user experience. At the same time, due to the characteristics of high efficiency, low cost and high quality of injection molding technology, automotive injection molded parts can be mass-produced and play an important role in automobile manufacturing.

- Body exterior parts: such as doors, rearview mirrors, hoods, bumpers, etc.

- Interior decoration parts: such as instrument panels, center consoles, seats, etc.

- Functional parts: such as lamps, fuel injectors, brakes, air-conditioning outlets

Inhaltsübersicht

ABOUT US

China automobile components casting manufacturer: Mindwell

Mindwell Company is a company specializing in the production of aluminum alloy, zinc alloy molds and zinc-aluminum die-casting product processing. The company is located in Xiamen, Fujian, China. It is one of the outstanding and leading companies integrating R&D, design, production and operation. An enterprise integrating mold design and production, die-casting, machining, and customized parts, with many years of professional production experience in aluminum alloy molds and aluminum alloy products, it has become an influential aluminum alloy die-casting manufacturer in China.

Mindwell has strong design and production capabilities. It mainly produces aluminum alloy and zinc alloy precision die-casting parts for automobiles, LED lamps, household appliances, motorcycles, power tools, motors, electronic accessories, etc. The company has passed the ISO9001: 2015 version of the quality system. Certification, establishing a strict and complete management system, the company implements the purpose of “keep improving and operating with integrity”, strives to continuously innovate and surpass on the existing basis, and firmly believes that: customer requirements are our pursuit.

Equipment currently owned:

- ——30 sets of 200T-1600T die-casting machines.

- ——2 200T hot zinc alloy die-casting machines.

- ——3 CNC machining centers, 3 engraving machines; 2 spark machines,

- CNC drilling machines: 4 units, radial drilling machines: 8 CNC lathes.

- ——5 hydraulic presses.

- ——20 automatic drilling and tapping machines

- ——One full-spectrum direct-reading spectrometer

- ——10 laser engraving machines

The company is fully equipped and equipped to provide customers with integrated services such as mold design and production, precision die-casting, CNC machining, and surface treatment, and provide high-quality products.

Sofortiges Angebot anfordern

Fordern Sie noch heute Ihr kostenloses Angebot für das Spritzgießen an und wir werden uns mit Ihnen in Verbindung setzen.

Automotive Casting: A Guide to Frequently Asked Questions

Aluminum die-casting is a kind of die-casting part produced by a mechanical die-casting machine. By pouring heated liquid aluminum or aluminum alloy into the feed port of the die-casting machine, the die-casting machine performs die-casting. The shape and size of the product are limited by the casting mold. Aluminum parts or aluminum alloy parts are often called aluminum die castings.

At Mindwell, we use high-quality aluminum materials and advanced die-casting technology. The automotive die-casting parts we produce include: aluminum die-cast automotive engine fittings, aluminum die-cast engine blocks, aluminum die-cast gasoline engine cylinder heads, aluminum die-cast valve rocker arms, and aluminum die-cast valves. Brackets, aluminum die-cast power parts, aluminum die-cast motor end covers, aluminum die-cast casings, aluminum die-cast pump casings, aluminum die-cast building parts, aluminum die-cast decorative parts, aluminum die-cast guardrail parts, aluminum die-cast aluminum wheels.

What are casting and die casting in the manufacturing process of automotive parts?

In the manufacturing process of automobile parts, casting and die-casting are one of the process methods of processing automobile parts, specifically in the field of metal processing.

- Casting: Casting is a method of pouring molten metal or alloy into a prepared mold, cooling and solidifying to obtain parts of the desired shape. During the casting process, the movement trajectory and parameters of the casting equipment can be controlled using programmed software technology to achieve precise casting operations. For example, large castings such as engine blocks, crankcases, transmission housings, etc. are usually produced using casting processes.

- Die casting: Die casting is a method of injecting molten metal or alloy into a mold under high pressure, and quickly cooling and solidifying to obtain parts of the desired shape. Die casting is usually suitable for the production of parts with complex shapes and high precision requirements. During the die-casting process, programmed software technology can be used to control parameters such as the movement trajectory, injection speed and pressure of the die-casting machine to ensure the quality and precision of parts. For example, automobile engine cylinder heads, transmission housings, brake calipers and other parts are usually produced using die-casting processes.

The application of advanced processing technology in the casting and die-casting process can improve the precision, quality and production efficiency of parts. By using the CNC control system, operators can write programs to accurately control various parameters during the casting or injection process, realize automated production, and reduce the impact of human factors on the quality of parts. At the same time, CNC machining can also provide more flexibility and adjustability to meet the needs of automobile parts of different models and specifications.

New Energy Vehicle Die Casting Parts Usage Guide

Die-casting parts for new energy vehicles are an important direction for the future development of the automotive industry. With the continuous improvement of environmental awareness, the market demand for new energy vehicles continues to increase. Die-cast parts, as an important part of new energy vehicles, will play an important role in future development.

Die-casting technology is a high-efficiency, high-quality part manufacturing method and is widely used in automobiles, aviation, machinery and other fields. The manufacturing of die-cast parts for new energy vehicles needs to have the characteristics of high precision, high strength, and high density to meet the requirements of new energy vehicles in terms of energy efficiency, safety performance, and driving distance.

The advantage of die-cast parts for new energy vehicles is that they can improve the overall performance of the vehicle, such as reducing vehicle weight, improving vehicle stability and safety. In addition, die-cast parts for new energy vehicles can also reduce vehicle fuel consumption and emissions, thus better meeting environmental protection requirements.

At present, the development and application of die-casting technology has made great progress, and the application of die-casting parts for new energy vehicles has become increasingly widespread. For example, lithium battery boxes, motor cases, steering gears, chassis parts, etc. are all common die-cast parts in new energy vehicles.

In the competition in the new energy vehicle market, the quality and technical level of die-casting parts will become the key to corporate competition. Therefore, enterprises need to focus on and improve die-casting technology and improve the quality and performance of die-cast parts to meet market demand.

To sum up, die-casting parts for new energy vehicles are an important direction for the future development of the automotive industry. Enterprises need to focus on and improve technology and continuously improve the quality and performance of die-cast parts to meet market demand and contribute to the development of the new energy automobile industry.

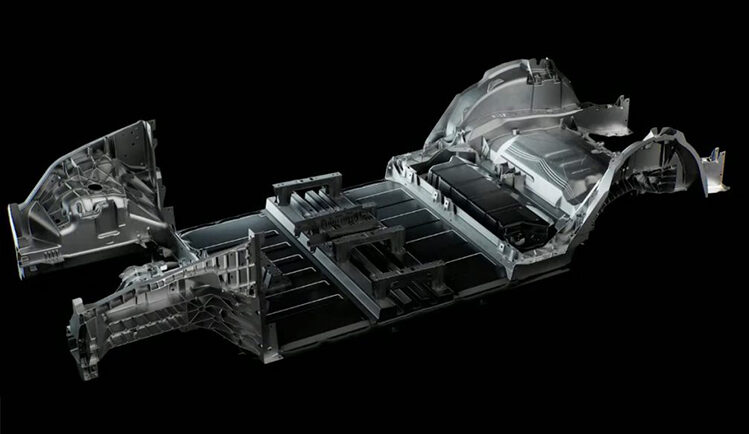

What is one-piece die-casting technology for automobiles?

In July 2019, Tesla issued a new patent, namely a multi-directional body-integrated casting machine and related casting methods for automobile frames, proposing a frame-integrated casting technology and related casting machine designs.

The traditional manufacturing process of automobiles mainly includes four major process links: stamping, welding, painting and final assembly. The integrated die-casting technology uses a super-large die-casting machine to mold hundreds of parts that need to be assembled in one go. Complete parts can be obtained directly. It requires 79 fewer parts than before and can reduce manufacturing costs by 40%.

Advantages of automotive integrated die-casting technology

- Save process: More than 70 parts and welding parts that need to be stamped can be omitted directly. Through integrated die-casting technology, the body can be directly die-cast.

- Time saving: shortening the manufacturing time from more than an hour to less than 3 minutes.

Machine saving: Originally, 300 robots were required in the manufacturing process, but now only one large die-casting machine is needed. - Manpower saving: The 300 workers originally required in the welding workshop can be reduced to only about 30 integrated die-casting machine maintenance personnel.

- Land saving: the floor space of the welding workshop can be greatly reduced, saving about 30% of the floor space than the previous design.

- Weight reduction: In terms of the entire vehicle, the rear floor assembly adopts integrated die-casting ModeI Y, which reduces the weight by about 30%, thereby increasing the cruising range by 14% and saving electricity bills.

- Cost saving: Compared with the original, manufacturing costs have been saved by about 40%, which has greatly improved ModeI Y in terms of both product strength and cost performance.

The technical barriers to the future of integrated die-casting

- In terms of materials, it mainly relies on heat-treated aluminum alloy materials.

- In terms of equipment, there are high requirements for the clamping force of die-casting machines. Die-casting machines have technical barriers to custom design and development, as well as relatively high capital expenditures.

- In terms of molds, integrated die-casting parts have complex structures and high manufacturing costs, as well as long preparation cycles, which place higher requirements on the production of die-casting molds.

- In terms of technology, since the current integrated die-casting technology is still in its infancy, die-casters need to have rich experience and technology accumulation in the production process to ensure the yield rate of mass production.

Issues that need to be paid attention to in integrated die casting

Pay attention to the cooperative relationship between automobile companies and third-party die-casting companies. If the cooperation changes or becomes unstable, it will have a great impact.

Since the parts are all die-cast into one, the repair cost will be very high in the event of a collision.

Die-casting process and surface treatment technology of auto parts

The die-casting process of automobile parts is a process of organic combination and comprehensive application of three elements: die-casting machine, die-casting mold, and alloy. The process of filling the cavity with metal during die casting is a process that unifies process factors such as pressure, speed, temperature and time. The process programming is based on the drawing requirements of the shell parts, fully considering the existing conditions, and utilizing the existing conditions as much as possible. Having the equipment to eliminate weak links in production, striving to improve product quality, and shortening the process preparation (manufacturing) cycle are issues that must be considered when planning the die-casting process for automotive parts.

Automotive die casting process flow:

- Plan review,

- Prepare materials,

- processing,

- Mold base processing,

- mold core processing,

- electrode processing,

- Mold parts processing,

- inspection,

- assembly,

- flying models,

- Mold testing

- production.

Aluminum casting process flow:

Furnace charge preparation: batching, feeding, melting, slag removal, transfer introduction, refining, introduction into holding furnace.

Die-casting of automotive parts: four steps: mold opening, die casting, post-processing, inspection/mold opening.

That is the design and manufacturing of molds. This needs to be considered based on product specifications and sizes, materials, usage environment and mold materials.

The whole process of die casting

Die casting is a process in which molten metal is injected into a mold through a die-casting machine, cooled, and then pushed out with a push rod. There are many relevant factors in this step, such as mold temperature, pouring temperature, raw material quality, injection speed, cooling speed, etc. Post-processing consists of multiple processing procedures aimed at improving corrosion resistance, wear resistance and texture of metal die castings through various treatments. Full inspection is where quality inspectors inspect the quality of die-casting parts, including appearance, size, performance, etc.

Advantages and applications of die-casting technology for automotive parts

Auto parts die-casting technology has advantages that other die-casting parts cannot match, such as appearance, light weight, corrosion resistance, etc., and is deeply loved by users. Especially since automobiles are lightweight, die-casting parts have been improved in the automotive electronics industry. One that is generally available. The engine block is the heart of the vehicle. The key issue in the quality of automotive service is whether the engine can work safely and with high quality, and one of the main components of the engine is the cylinder block.

Cylinder blocks are generally made of high-pressure casting or sand casting, but judging from the current mainstream models of automobile engines and automobile manufacturers, aluminum alloy die-cast cylinders are used. Although the manufacturing cost of aluminum alloy die-cast cylinders is higher than the previous two, with the demand for engine oil and lightweight vehicles, the rise of aluminum alloy die-cast cylinders is increasingly adopted by automobile manufacturers.

Because aluminum alloys have better thermal conductivity than cast iron, aluminum cylinder heads and blocks can improve the appearance of the engine. The casting process of the cylinder block is very complicated. The composition and strength of aluminum alloy auto parts die-casting parts have an important impact on the quality of the die-casting parts. By adjusting relevant components, the tensile strength and fluidity of die castings can be improved.

When choosing a processing method for CNC machining of automotive parts, factors such as material, shape, size, etc. must be considered.

During the CNC machining process of auto parts, it is usually necessary to choose a suitable CNC machining method to meet production needs. When selecting a processing method, factors such as the material, shape, and size of the parts need to be considered. For auto parts processing, both five-axis and four-axis machining have their advantages and limitations. Let’s analyze the issue of choosing between five-axis machining and four-axis machining.

First of all, four-axis processing refers to adding a rotation axis to the three-axis, which can realize processing at any angle in the plane, and is suitable for processing a large number of similar or simple parts. Five-axis machining adds an inclined axis to the four-axis to enable more complex parts processing, such as curved surface processing and special-shaped parts processing.

Secondly, five-axis machining has higher accuracy and better surface quality, and can achieve more stringent processing requirements. Four-axis machining can only process in a plane and cannot meet the high-precision requirements of five-axis machining.

However, the equipment cost of five-axis machining is relatively high, maintenance is difficult, and it requires higher technical level and experience. The equipment cost of four-axis machining is relatively low, maintenance is relatively simple, and the operation difficulty is low.

To sum up, the choice between five-axis machining and four-axis machining needs to be determined based on the specific situation. If the shape of the auto parts is complex and requires high precision and high surface quality, then five-axis machining should be chosen; if the shape of the auto parts is relatively simple and the requirements are not too high, then four-axis machining can meet the needs. Of course, for some special parts processing tasks, other processing methods may need to be used, and the choice needs to be based on the actual situation.