Moulage par injection d'ABS

ABS is a commonly used thermoplastic characterized by its toughness, impact resistance and heat resistance. In the injection molding process, ABS material is melted and injected into a mold, where it solidifies and forms the shape of the mold cavity. The mold is then opened and the parts removed. ABS injection molding is widely used in various industries such as automobiles, electronics, consumer goods, and medical devices.

MINDWELL's ABS Injection Molding Process

ABS engineering plastics is one of the materials MindWell uses most in injection molding process manufacturing, because ABS injection molded parts have the advantages of high strength, good dimensional stability, easy processing and good chemical resistance.

Our company has ABS injection molding to produce all kinds of parts, which are used in various industries. The following are the industries we often use and some experience:

- ABS plastic has good strength and impact resistance, and can be used in production to make products that require strength and durability, such as mechanical parts and electrical casings.

- ABS plastic has good acid and alkali resistance, and it is excellent in the manufacture of moisture-proof packaging such as cosmetic boxes and pharmaceutical packaging.

- ABS plastic is also widely used in the production of shoes. The midsole materials of most sneakers are ABS solid products, while the uppers are made of other materials, such as PU, EVA, etc.

- In the automobile manufacturing industry, ABS plastic is mainly used to manufacture plastic body parts, such as door handles, projectors, glass regulators, etc. ABS plastic is widely used in the automotive field because of its good gasoline resistance, wear resistance and high temperature resistance.

Get Started Now with Custom ABS Injection Molding Services According to Your Needs!

Advantages of ABS injection molding materials

- Good heat resistance: ABS materials can withstand higher temperatures, usually around 80°C, and even above 100°C under certain conditions.

- Chemical corrosion resistance: ABS material has good corrosion resistance to acids, alkalis, salts and other chemicals.

- Good mechanical properties: ABS material has good mechanical properties such as impact resistance, abrasion resistance and tensile resistance.

- Good processing performance: ABS material is easy to process, cut, punch, plastic deformation, etc., and it is also easy to carry out various surface treatments.

- Good resistance to infrared light: ABS material has good resistance to infrared light and can be used at higher temperatures.

- Durable: The ABS material is very durable and can withstand long-term use and repeated use, while also resisting corrosion.

- Good electrical insulation performance: ABS material has good insulation performance and is not easy to conduct electricity. It can be used in the manufacture of shells, sockets and other structures and parts of many electrical and electronic equipment.

Matériaux connexes pour le moulage par injection

pvc Injection Molding

Moulage par injection de polyéthylène

Moulage par injection de polycarbonate

Moulage par injection d'EPI

Moulage par injection de PP

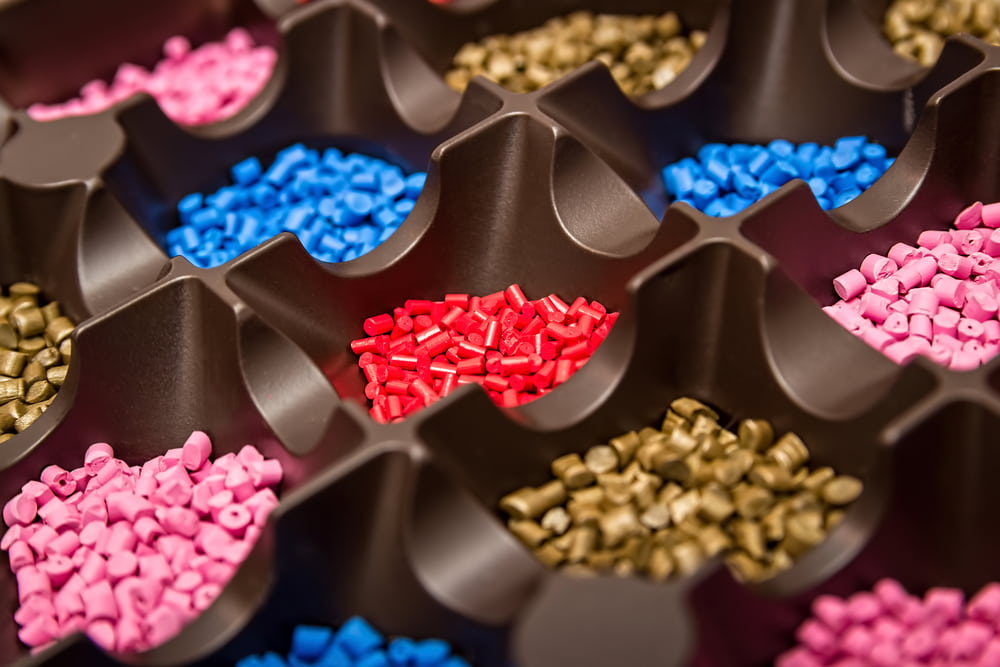

ABS injection molded parts produced by MindWell