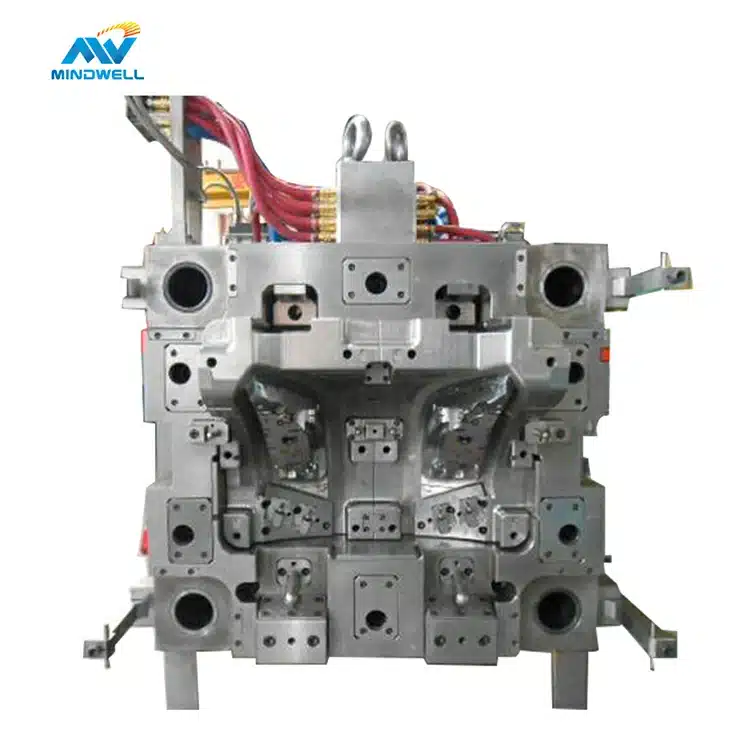

Fabrication de moules

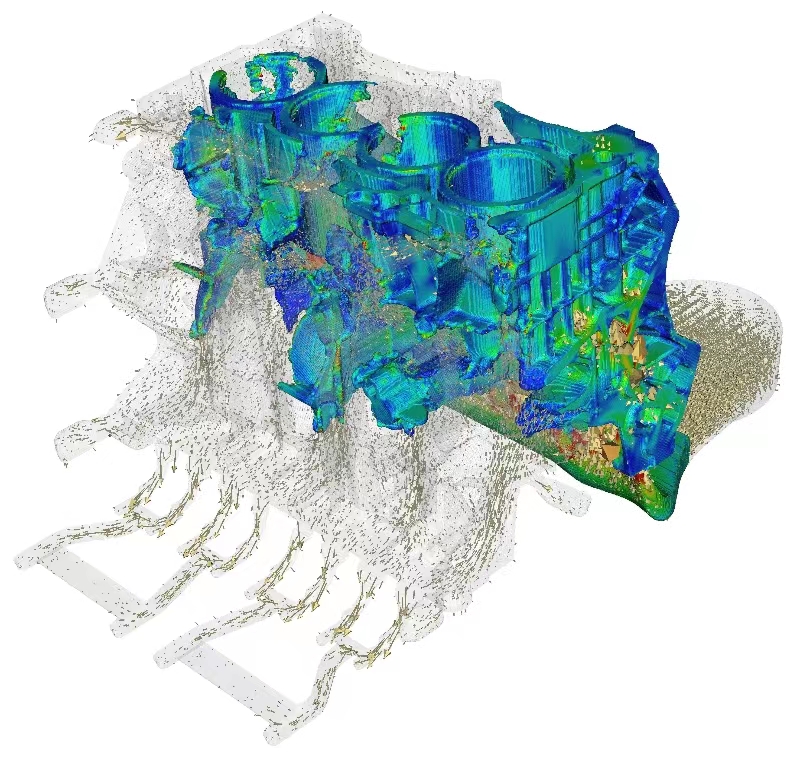

En tant que professionnel mold manufacturing company, MindWell has modern equipment and adopts the most advanced manufacturing technology. Among them, Swiss Charmilles wire cutting machine, Japanese animal husbandry processing center, and Japanese animal husbandry spark machine are all relatively advanced manufacturing equipment on the market at present, which can meet different processing needs.

- Modern equipment and state-of-the-art manufacturing technology

- The maximum mold processing can reach 10 tons

- The company's processing accuracy can reach 0.005mm

MindWell is a mold manufacturing company

MNW’s mold manufacturing equipment and manufacturing technology are among the leading companies in the industry. We can manufacture high-quality molds and meet the needs of different customers. This is also an important reason why MNW has gained a good reputation and long-term cooperative customers in the market.

Processing Equipment

The company's processing accuracy can reach 0.005mm, which not only demonstrates the high precision and high efficiency of its equipment, but also provides a reliable guarantee for improving product quality.

Processing Equipment

The company has advanced processing machinery, and the maximum mold processing can reach 10 tons. This data shows that the company can manufacture large molds and provide customers with a wider range of choices.

Get Started Now with Custom Mold manufacturing According to Your Needs!

Selection of mold processing materials

For mold materials with special requirements, various high-grade alloy steels, such as high-speed steel and high-temperature alloy steel, can be considered. In addition, MNW selects excellent mold steel manufacturers to ensure the quality and reliability of materials.

The selection of materials in mold manufacturing should be considered according to the specific mold type, working environment, use requirements, processing difficulty and other aspects. The following are some common material selection references:

- Cold/hot pressing mold: H13 steel, 1.2344 steel, 1.2343 steel, 8407 steel, NAK80 steel, etc.

- Plastic mold: P20 steel, 718 steel, 2738 steel, Nak55 steel, etc.

- Sheet metal mold: DC53 steel, SKD11 steel, SKD61 steel, etc.

Mold Library

Our company has more than ten years of experience in mold manufacturing, and has produced many molds, including injection molds, die-casting molds, etc.

Questions fréquemment posées

A: Mold making is a manufacturing process used to produce various precision components and parts. Mold making involves designing, building, forming and machining, which can be used to produce parts from plastic, metal, rubber and other materials.

A: Mold manufacturing has a wide range of applications in many fields, including automotive, electronics, aviation, aerospace, medical, consumer goods, and construction.

A: The process of mold manufacturing includes steps such as design, manufacturing parts, assembly, testing and trimming. Design is the starting point of mold manufacturing, which will determine the direction of the entire manufacturing process. Manufacturing parts includes operations such as cutting, drilling, milling, turning, and more. Assembly is the assembly of manufactured parts into a complete mold. Testing and trimming is the process of inspecting and trimming molds before final product.

A: The life of the mold depends on many factors, such as the material of the mold, frequency of use, design and maintenance, etc. The life of a mold can usually be extended with regular maintenance and reconditioning.

A: Mold maintenance includes processes such as cleaning, oiling and trimming. Cleaning is key to ensuring mold surfaces stay clean. Oiling is the key to making sure the mold works unhindered. Trimming is the key to replacing or repairing components of a mold to ensure proper functioning.

A: Mold manufacturing has advantages in many aspects, such as the ability to produce a large number of identical parts, which can increase production efficiency, can reduce costs, can control manufacturing quality and details, and can conduct complex manufacturing processes, etc.

Obtenir un devis immédiat

Demandez dès aujourd'hui votre devis gratuit pour le moulage par injection et nous vous contacterons pour établir la communication.