In several sectors, die cast aluminum alloys are the preferred option for producing robust and long-lasting products. These alloys are now widely used in everything from consumer goods and electronics to automotive and aerospace applications because of their remarkable strength, adaptability, and affordability.

What is aluminum alloy die-casting?

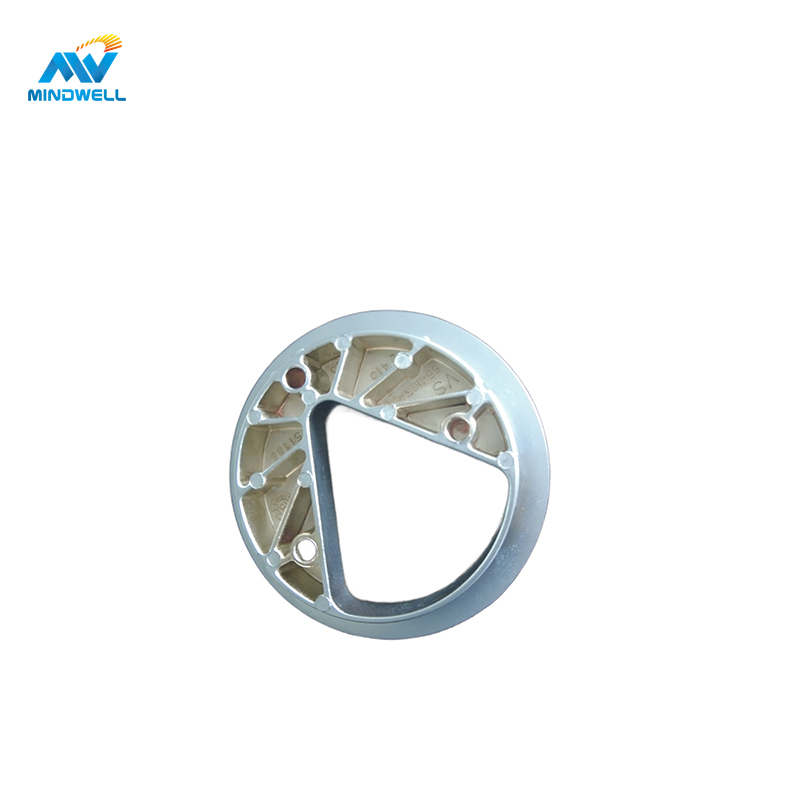

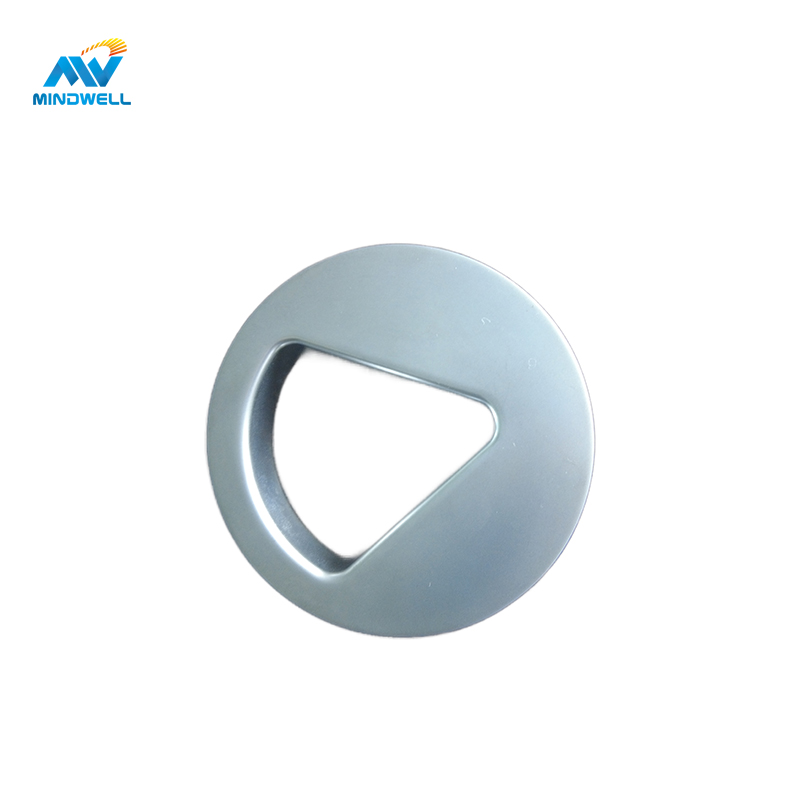

One kind of metal alloy created by die-casting is aluminum alloy. Melted aluminum is poured under intense pressure into a mold, where it solidifies and takes on the shape of the mold. The end result is a lightweight, robust component with superior surface polish and dimensional precision.

Advantages of die-cast aluminum alloy

- Strength: The outstanding strength-to-weight ratio of die-cast aluminum alloy is one of its key benefits. Because of their great tensile strength, these alloys can endure severe conditions and large loads without losing functionality.

- Die-cast aluminium alloys exhibit great versatility since they may be readily tailored to fulfil certain design specifications. Their broad variety of mechanical and physical qualities make it simple for producers to produce precise features and complicated designs.

- Excellent corrosion resistance is a feature of aluminum’s natural oxide layer formation on the surface. Die-cast aluminum alloys increase this benefit by adding alloying elements that improve their resistance to corrosion, which qualifies them for use in outdoor and marine environments.

- Thermal conductivity: Die-cast aluminum alloy dissipates heat rapidly and has good thermal conductivity. Because of this characteristic, it’s perfect for industries like electrical equipment and automobile engines where temperature control is crucial.

- Economical: Die-cast aluminum alloy offers an economical way to produce intricate pieces. Compared to other manufacturing techniques, the die-casting process offers great productivity and minimum material waste, which lowers production costs.

Application of die-cast aluminum alloy

Many different industries employ die-cast aluminum alloys, including:

- Automobile: Die-cast aluminum components’ excellent strength and low weight make them popular in the automobile sector. They are present in many different parts, including suspension parts, engine blocks, and gearboxes.

- aircraft: Die-cast aluminum alloys’ exceptional strength-to-weight ratio is essential to the aircraft sector. These alloys are used in the construction of wing structures, landing gear, and engine components for airplanes.

- Electronics: Because of its electrical and thermal conductivity, die-cast aluminum alloy is often used in the electronics sector. They are used in casings, dissipateurs thermiques, and other parts that need effective heat dissipation.

- Consumer goods: Die-cast aluminum alloys are often used in the manufacturing of household goods including power tools, sports equipment, and kitchen appliances. Their durability, low weight, and attractive appearance make them a preferred option for producers.

Choose the right die-cast aluminum alloy

It is important to take into account many characteristics including heat conductivity, corrosion resistance, and mechanical qualities when choosing a die-cast aluminum alloy for your particular application. Getting advice from an experienced manufacturer or supplier might help you choose the alloy that will work best for you.

Several frequently used die-cast aluminum alloys include:

- ADC12: This alloy resists corrosion well, casts easily, and is very strong. It is often used in electrical and automotive applications.

- A380: This material is renowned for having good dimensional stability and flowability. often used in the manufacturing of intricate parts with thin walls.

- AlSi9Cu3: This alloy has a reputation for having outstanding machinability and strong thermal conductivity. It is often used in electronic enclosures and heat sinks.

en conclusion

Die-cast aluminum alloys are an economical and adaptable choice for many different sectors. It is perfect for applications requiring lightweight, long-lasting components because of its remarkable strength, adaptability, and resistance to corrosion. Working with a reliable manufacturer and selecting the appropriate die-cast aluminum alloy can help you guarantee a high-quality product that satisfies your unique needs.