Une technique de production très efficace et adaptable, moulage sous pression de l'aluminium est utilisée pour créer avec précision des composants en aluminium complexes et détaillés. Parce qu'elle permet de produire des formes complexes, des tolérances précises et des produits finis de haute qualité, cette technologie est devenue de plus en plus populaire dans divers secteurs. Les principes, les avantages et les utilisations du moulage sous pression de l'aluminium seront abordés dans cet article.

Qu'est-ce que le procédé de moulage sous pression de l'aluminium? ?

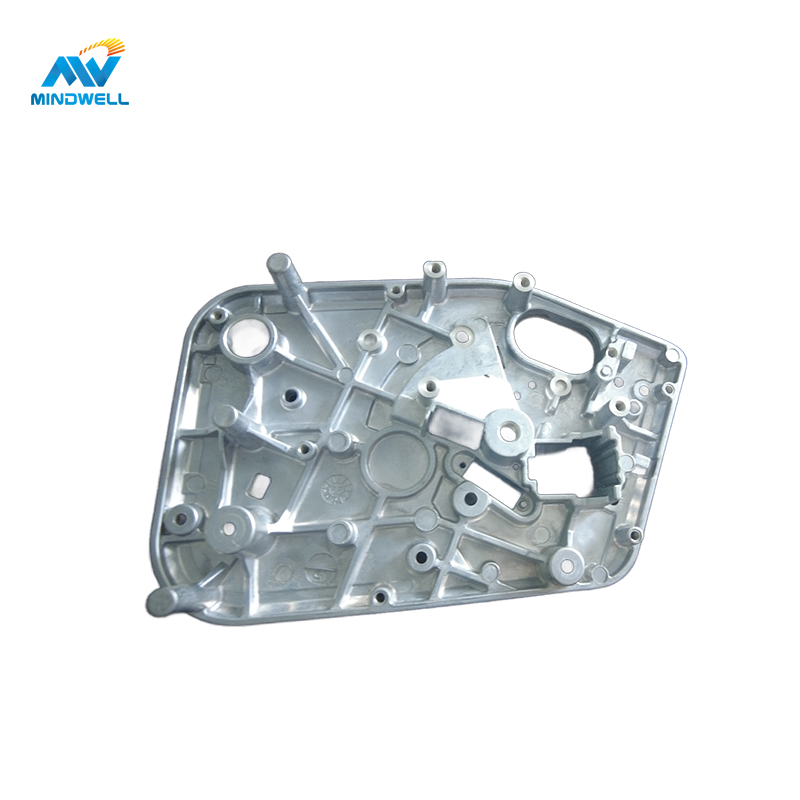

Une technique de fabrication sophistiquée, le moulage sous pression de l'aluminium, est utilisée pour créer avec précision des composants métalliques complexes et détaillés. Pour créer des formes complexes et des tolérances précises, l'aluminium en fusion est injecté sous haute pression dans la cavité d'un moule. La préparation du moule, l'injection de l'aluminium en fusion, le refroidissement, la solidification et l'éjection de la pièce moulée sont les étapes essentielles du processus de moulage sous pression de l'aluminium.

La principale caractéristique du moulage sous pression de l'aluminium est sa pression et sa vitesse d'injection élevées, qui permettent au métal de remplir rapidement les coins du moule et de produire des pièces d'une grande précision et d'une grande densité. La majorité des pièces moulées sous pression n'ont pas besoin d'être ébavurées, percées ou taraudées une fois produites.

En outre, l'aluminium étant très résistant et léger, les pièces moulées sous pression en aluminium peuvent remplacer une partie de l'acier dans un produit, réduisant ainsi son poids total sans sacrifier sa résistance.

Procédé de moulage sous pression de l'aluminium :

Préparation des moules :

La première étape de la procédure consiste à créer un moule métallique dans la forme du composant requis. Ce moule est généralement en acier ou en fer. La pression et la température élevées impliquées dans le processus de moulage sont censées être tolérées par le moule.

L'aluminium en fusion est injecté.

L'aluminium est fondu dans un four, puis versé dans le moule à une pression très élevée, souvent comprise entre 1 500 et 25 000 psi (livres par pouce carré). L'aluminium peut également être recyclé. Cette pression élevée garantit que le métal fond entièrement dans les cavités du moule.

Le processus de refroidissement et de solidification.

Après avoir rempli le moule, l'aluminium en fusion refroidit et se solidifie, prenant ainsi la forme du moule. Pour garantir les qualités correctes du matériau et éviter les défauts, le processus de refroidissement est minutieusement réglementé.

Retrait de la coulée :

Le composant en aluminium fraîchement formé est démoulé une fois qu'il s'est solidifié. Le moule peut ensuite être réutilisé pour d'autres coulées.

Comment fonctionne le procédé de moulage sous pression ?

- Après avoir été chauffé à son point de fusion, le métal en fusion se transforme en liquide.

- Une pression élevée est utilisée tout au long du processus de moulage sous pression pour forcer rapidement le métal liquide à pénétrer dans la cavité précise du moule métallique.

- Le métal en fusion se refroidit et se solidifie sous pression pour créer le moulage souhaité.

- Ouvrir le moule de coulée sous pression, retirer la pièce moulée et terminer le processus de coulée sous pression après la prise complète du métal liquide.

Les deux techniques fondamentales de production de pièces moulées sous pression en aluminium sont le moulage sous pression à chambre froide et le moulage sous pression à chambre chaude. Le métal fondu est versé dans la chambre de pression d'une machine de coulée sous pression à chambre froide à l'aide d'un système de coulée manuel ou automatisé. Le métal est ensuite forcé hydrauliquement dans la cavité du moule par le poinçon d'injection au fur et à mesure qu'il avance. Dans la méthode de coulée sous pression à chambre chaude, la chambre de pression est positionnée perpendiculairement au creuset. Le métal fondu entre automatiquement dans la chambre de pression par l'orifice d'alimentation et le poinçon d'injection descend pour forcer le métal fondu dans la cavité du moule.

Avantages du moulage sous pression de l'aluminium :

- Précision et densité élevées : L'injection à haute pression peut garantir une précision et une densité élevées dans les pièces moulées en aluminium, ce qui permet d'obtenir des produits de meilleure qualité.

- Idéal pour les moulages massifs en aluminium : la technique de moulage sous pression de l'aluminium permet de produire des moulages de grande taille, ce qui la rend idéale pour les grandes applications industrielles.

- Efficacité de production élevée : Le moulage sous pression de l'aluminium permet de fabriquer constamment un grand nombre de pièces et d'accroître l'efficacité de la production, car il peut se solidifier rapidement sous haute pression pour former le produit requis.

- Coûts de production minimes : La méthode de moulage sous pression de l'aluminium consiste à injecter du métal en fusion dans un moule, qui se solidifie rapidement sous haute pression pour créer le résultat souhaité. Le coût de production est peu élevé car cette technologie permet de créer un grand nombre de composants de petite et moyenne taille tout en économisant beaucoup d'énergie et de ressources.

- Grande précision de fabrication : La précision des produits manufacturés peut approcher le millimètre puisque le moulage sous pression de l'aluminium est produit de manière entièrement automatisée.

- Qualité stable des produits : La technologie de traitement du moulage sous pression de l'aluminium peut éliminer le travail manuel et prévenir les problèmes de qualité des produits dus à des facteurs humains. Simultanément, chaque étape du processus de fabrication, y compris le choix des matières premières, garantit que les produits sont de la plus haute qualité.

- Le moulage sous pression de l'aluminium présente un temps de cycle rapide et une grande efficacité de production par rapport à d'autres méthodes de fabrication. Dans la plupart des cas, l'ensemble du processus, de la conception du produit à sa fabrication, ne prend que quelques semaines. L'efficacité de la production de l'entreprise peut être considérablement accrue par ce cycle de fabrication rapide.

- Grande plasticité : Le procédé de moulage sous pression de l'aluminium permet de fabriquer des produits de formes variées. En outre, le moulage précis de l'aluminium sous pression peut satisfaire les demandes des différentes industries en matière de formes de produits grâce à la grande plasticité de l'aluminium.

- Protection de l'environnement et économie d'énergie : La méthode de fabrication du moulage sous pression de l'aluminium utilise un alliage d'aluminium fondu au lieu de solvants, d'adhésifs ou d'autres produits chimiques dangereux, ce qui satisfait aux normes de protection de l'environnement et d'économie d'énergie. Afin de recycler les ressources et de réduire les coûts de fabrication, les déchets d'aluminium peuvent également être recyclés pendant la fabrication du produit.

Moulage sous pression et moulage sous pression de l'aluminium

L'aluminium et d'autres métaux sont coulés selon deux procédés différents : le moulage sous pression (HPDC) et le moulage sous pression (LPDC). C'est au niveau de la pression utilisée pendant le processus de coulée que ces techniques divergent le plus.

Moulage sous haute pression (HPDC) :

Processus:

- Dans le cas du HPDC, le métal en fusion est injecté à grande vitesse et à haute pression dans une cavité de moule métallique.

- La haute pression est maintenue tout au long du processus de solidification afin de garantir la formation de pièces moulées détaillées et précises.

Pression :

En règle générale, le moulage sous pression implique des pressions allant de 10 000 à 30 000 psi (70 à 200 MPa).

Avantages :

- Des taux de production élevés : HPDC est connu pour sa capacité à produire rapidement de grandes quantités de pièces complexes et de haute intégrité.

- Excellente précision dimensionnelle et finition de surface.

- Convient pour les parois fines et les dessins complexes.

Inconvénients :

- Equipment costs can be relatively high.

- Tooling costs are significant.

- Limited to smaller casting sizes compared to low-pressure processes.

Die Casting at Low Pressure (LPDC):

Method:

Melted metal is poured into the mold using a regulated low-pressure mechanism in LPDC.

Usually, throughout the casting process, the pressure is kept at a lower level.

Apply pressure:

Generally speaking, LPDC operates at lower pressures, between a few hundred and several thousand psi (about 0.07 and 3 MPa).

Benefits

- less expensive tools and equipment than high-pressure procedures.

- Ideal for bigger, more substantial castings.

- Reduced turbulence in the molten metal may lead to a decrease in the number of gas porosities.

Drawbacks:

- lower output rates in contrast to die casting at high pressure.

- may not be able to achieve elements that are really complex and elaborate.

A number of variables, including the part’s size and complexity, production volume, financial concerns, and necessary material qualities, must be taken into account when deciding between high-pressure and low-pressure die casting. Low-pressure die casting could be more appropriate for bigger, simpler parts with lower production quantities, whereas high-pressure die casting is often used for high-volume manufacturing of smaller, intricate components. The choice of procedure is contingent upon the particular demands of the casting project, since each method has a unique combination of benefits and drawbacks.

Why is aluminum material suitable for high-pressure die casting?

The reasons why aluminum materials are suitable for high-pressure die-casting are as follows:

- Low melting point: Aluminum has a relatively low melting point, about 660°C, which makes it easy to melt and inject into molds under high pressure.

- Good fluidity: Aluminum has good fluidity and can be smoothly injected into fine parts of the mold under high pressure to obtain a complete product.

- Good corrosion resistance: Aluminum is a corrosion-resistant material that does not easily react with oxygen, carbon dioxide, water, and other substances in the air, so it can maintain its performance and appearance for a long time.

- Moderate density: The density of aluminum is relatively low, about 2.7 g/cm2, which means aluminum products are lightweight and easy to transport and use.

- Recyclable: Aluminum is a recyclable material that meets the requirements of sustainable development.

- To sum up, the reason why aluminum material is suitable for high-pressure die-casting is mainly due to its low melting point, good fluidity, good corrosion resistance, moderate density and recyclability.

High-Pressure Aluminum Die Casting Applications:

Automobile Sector:

Automobile structural elements, engine components, and gearbox cases benefit from high-pressure die-cast aluminum’s strength and lightweight qualities.

Electronics for consumers:

This method is often used to create housings for complex components such as heat sinks and electrical gadgets.

Airspace:

High-pressure die-cast aluminum is lightweight and strong, making it a great choice for a variety of aviation components, including housings and structural sections.

Engineering in general:

A large variety of components for tools, machinery, and industrial equipment may be produced because to the process’s adaptability.

A popular and effective technique for creating aluminum components that satisfy industrial requirements and high quality standards is high-pressure aluminum die casting. Because of its capacity to create intricate forms and preserve dimensional precision, it is essential to the production of many goods in a variety of industries.

Conclusion :

High-pressure aluminum die casting is a sophisticated and efficient manufacturing process that has revolutionized the production of complex aluminum components. Its ability to achieve high precision, cost-effectiveness, and versatility makes it a preferred choice across diverse industries, driving innovation and advancements in product design and manufacturing. As technology continues to evolve, high-pressure aluminum die casting is likely to play a crucial role in shaping the future of manufacturing.

What are 3 limitations of high pressure die casting?

High-pressure die casting (HPDC) has several drawbacks in addition to its numerous benefits. The following three main restrictions apply to high-pressure die casting:

Costs of tooling:

For high-pressure die casting, the initial tooling costs might be somewhat substantial. It takes a lot of money to create the molds, or die tooling, that are used to shape and form the molten metal. The complexity and expense of their manufacturing are increased by the molds’ need to endure high pressures and temperatures. Tooling expenses may be a big issue, especially when developing prototypes or limited production runs.

Limited Choice of Alloys:

Alloys that exhibit excellent fluidity and castability at elevated temperatures are often suitable candidates for high-pressure die casting. Due to their advantageous qualities, aluminum and zinc are often employed in HPDC; nevertheless, certain alloys that have poor castability or are prone to porosity at high pressures may not be as well suited for the process. Certain specific alloys could require different casting techniques or adjustments to the process parameters.

Limitations on Part Size:

Smaller to medium-sized components are often better suited for high-pressure die casting. The size and weight of the pieces that can be produced efficiently may be restricted by the machinery and equipment employed in the process. It might be difficult to cast larger, heavier components using high-pressure die casting methods. Other casting techniques, including sand casting or low-pressure die casting, can be better suited for bigger pieces.

It’s crucial to remember that high-pressure die casting is still appropriate for many applications despite these drawbacks. The method is still very useful for producing a variety of components, especially those that need to be produced in huge numbers with a high degree of accuracy and complexity. However, while choosing a casting technique for a particular project, designers and manufacturers should carefully analyze these limits and assess if high-pressure die casting fits with their needs and limitations.

What are the pressures for die casting?

Die casting is a process that creates intricate and precise objects by forcing molten metal under great pressure into a mold chamber. One important factor influencing the speed, integrity, and quality of the casting process is the pressure applied during the die casting process. The material being cast, the size and complexity of the component, and the particular die casting technique (e.g., high-pressure die casting or low-pressure die casting) may all affect the required pressure. The following are typical pressure ranges for several die casting types:

High-Pressure Die Casting (HPDC):

The pressure range often used in high-pressure die casting is 10,000 to 30,000 psi (70 to 200 MPa).

During the injection step, considerable pressure is used to guarantee that the molten metal fills the mold cavity fully and quickly.

Low-Pressure Die Casting (LPDC):

In contrast to high-pressure die casting, low-pressure die casting employs lower pressures.

Generally speaking, pressures in LPDC vary from a few hundred to a few thousand psi (or from 0.07 to 3 MPa).

Throughout the casting process, the lower pressure is maintained, enabling a slower, more deliberate fill of the mold.

Gravity Die Casting:

Melted metal is poured into the mold using gravity in gravity die casting, rather than using a lot of external pressure.

The height at which the molten metal is poured determines the pressure in gravity die casting, which is much lower than in high-pressure die casting.

It’s crucial to remember that the precise pressure needs might change depending on the alloy being cast, the part’s design, and the casting apparatus used. In order to achieve full mold filling, reduce errors, and guarantee the manufacture of castings of superior quality, pressure is an essential element.

The pressure numbers shown here are just suggestions; the actual pressures used in die casting may vary according to the particular needs of the project and the equipment’s capacity. In order to achieve the intended outcomes, casting process optimization requires careful consideration of these characteristics by designers and manufacturers.

Why does high pressure die casting?

For the manufacturing of intricate metal components, high-pressure die casting (HPDC) is used for a number of reasons, chief among them being the benefits it provides in terms of effectiveness, accuracy, and affordability. Here are several main justifications for the widespread usage of high-pressure die casting:

Quick Production:

High-pressure die casting makes it possible to produce intricate pieces quickly and precisely in huge numbers.

The method allows for quick cycle times, which makes it appropriate for large-scale production.

intricate geometries:

For casting complicated, detailed forms with precise features, HPDC is a good fit.

High pressure is used throughout the casting process to guarantee that molten metal fills complex mold cavities, resulting in components with fine details and tight tolerances.

Dimensional Precision:

Excellent dimensional precision and reproducibility are the outcome of maintaining a high pressure during the whole solidification process.

High-pressure die-casting components usually don’t need much further machining.

Slender Walled Areas:

Lightweight components and thin-walled sections may be produced using high-pressure die casting without compromising structural integrity.

Because of this, the procedure may be used in situations when losing weight is essential.

Superior Material Integrity:

The cast pieces’ material integrity is improved and porosity is reduced thanks to the high pressure.

Better mechanical qualities, such increased strength and enhanced surface polish, are the outcome of this.

Economical for Large Volumes:

Large production runs make high-pressure die casting cost-effective, despite the potentially expensive initial tooling costs.

The low amount of post-casting machining and high production rates add to the overall cost effectiveness.

Versatility of Alloy:

High-pressure die casting is a flexible process that works with a variety of alloys, the most popular ones being zinc and aluminum.

This makes it possible to choose materials with flexibility in accordance with certain performance criteria.

Diminished Waste:

Reduced scrap and material waste are a result of the die casting process’s great accuracy and control.

The need for extra material reduction is reduced when near-net-shape components may be produced.

Even though high-pressure die casting has several benefits, it’s important to take the particular needs of a given application into account. When selecting the best casting technique, consideration should be given to elements including component size, complexity, production volume, and material qualities.

What type of aluminum is used for die casting?

Good mechanical qualities, outstanding castability, and resistance to the high pressures and temperatures needed in the die casting process define aluminum alloys that are often used in die casting. The following aluminum alloys are most often used in die casting:

1. Aluminum Alloy 380 (A380):

One of the most popular alloys of aluminum for die casting is A380.

It has excellent machining and casting qualities.

Because of its exceptional fluidity, the A380 is a good choice for manufacturing intricate components with thin walls.

2. Aluminum Alloy 383 (A383):

A383 and A380 are comparable, while A383 has better resistance to heat cracking.

It is very useful for die casting complex components because of its increased fluidity.

3. Aluminum Alloy 360 (A360):

High strength, superior resistance to corrosion, and exceptional pressure tightness are attributes of A360.

It is often used for items that need to be machined as well as cast.

4. Aluminum Alloy 413 (A413):

Excellent fluidity and pressure tightness are provided by A413.

It is often applied to components that need to be very durable and resistant to corrosion.

5.Aluminum Alloy 390 (A390):

Excellent corrosion resistance and pressure tightness are two of A390’s best qualities.

It is often used in applications needing high-performance qualities, such as automobile components.

6. Aluminum Alloy 356 (A356):

The popular aluminum-silicon alloy A356 is renowned for its excellent casting qualities and thermal treatability.

It provides an excellent balance of corrosion resistance, ductility, and strength.

7. Aluminum Alloy 319 (A319):

When applications call for more fluidity and pressure tightness than some other alloys, A319 is often used.

The requirements of the application, which include elements like mechanical qualities, corrosion resistance, thermal conductivity, and economic considerations, determine which particular aluminum alloy is best for die casting. Depending on how these qualities need to be balanced for a given part or application, several alloys may be used. It’s also important to remember that new aluminum alloys may eventually be used in die casting applications as a result of developments in die casting technology and alloy development.

What is the difference between die casting and high pressure die casting?

Although die casting and high-pressure die casting are similar techniques, they are often used synonymously. There is a little difference between the two, however. Let’s explain the distinction:

Die Casting:

Definition: The technique of pumping molten metal into a mold, or die, to create a particular form or component is known as die casting.

Alternatives: Depending on the pressure used during the casting process, die casting may be roughly divided into several categories. These variations include gravity die casting, low-pressure die casting, and high-pressure die casting.

Pressure Range: Generally speaking, die casting may entail a variety of pressures. There are variations for both high and low pressures.

High-Pressure Die Casting (HPDC):

Definition: The method of die casting in which molten metal is pumped into a mold at high pressures is known as high-pressure die casting.

Features: During the injection phase of an HPDC, pressures usually vary from 10,000 to 30,000 psi (70 to 200 MPa).

Benefits: HPDC is renowned for its quick turnaround times on intricate, high-precision products with superior surface polish and dimensional accuracy.

Materials: often used for alloys made of zinc and aluminum.

To sum up, not all die casting is high-pressure die casting; nonetheless, all die casting is die casting. The phrase “die casting” refers to a group of procedures that include the injection of molten metal into a mold, sometimes at different pressures. High-pressure die casting is a subclass of die casting that focuses on using high injection pressures to obtain certain benefits including high material integrity, quick manufacturing, and complex component geometries.