Pengecoran Mati Paduan Magnesium

Paduan magnesium adalah bahan logam yang ringan dan berkekuatan tinggi. Bahan ini memiliki ketahanan kompresi, ketahanan lelah, ketahanan guncangan dan sifat redaman yang sangat baik. Karena kemampuannya yang ringan dan kompatibilitas elektromagnetik yang baik. Saat ini, bahan paduan magnesium yang umum adalah AZ91, AM60, AZ31, WE43, ZE41, dll. Mereka memiliki kekuatan, plastisitas, dan ketahanan korosi yang berbeda, yang dapat memenuhi kebutuhan berbagai bidang.

Perusahaan die casting OEM

Proses die casting magnesium MindWell

Ada beberapa jenis proses pengecoran magnesium alloy, termasuk die casting, sand casting, dan investment casting. Tergantung pada aplikasi yang diinginkan dan persyaratan produksi, kami dapat menawarkan layanan proses yang berbeda.

Mencair dan menuangkan

Magnesium dilebur dalam tungku dan dituangkan ke dalam cetakan yang telah dipanaskan sebelumnya.

Pendinginan

Cetakan yang berisi magnesium cair mendinginkan dan memadatkan logam, membentuk bentuk yang diinginkan.

emoval

Setelah logam mengeras sepenuhnya, produk cor dikeluarkan dari cetakan dengan menggunakan berbagai teknik seperti ejektor mekanis atau pukulan hidrolik.

Penyelesaian

Setelah dilepas, produk cor melalui proses finishing untuk menghilangkan tepi kasar atau ketidaksempurnaan permukaan.

Pemesinan dan perakitan

Terakhir, coran magnesium menjalani pemrosesan lebih lanjut, seperti pemesinan dan perakitan, sebelum siap digunakan.

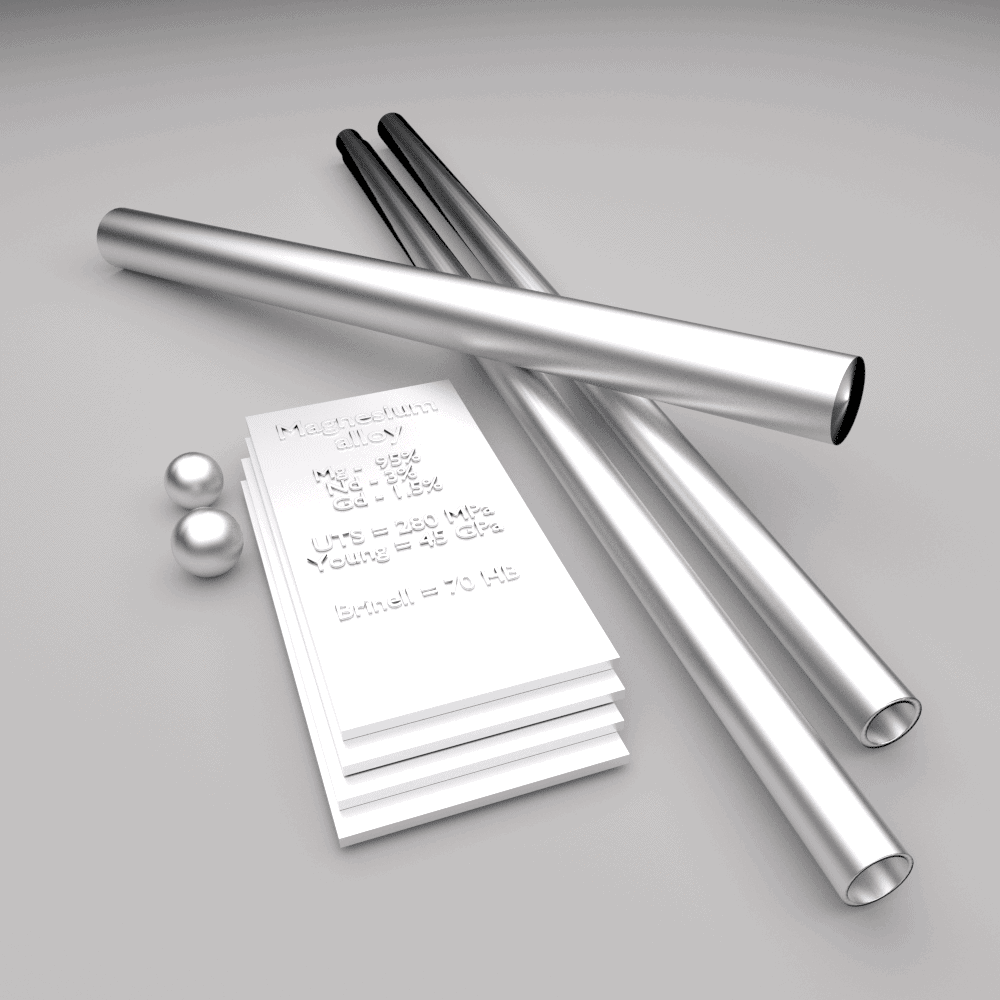

Apa saja bahan dari paduan magnesium

Paduan magnesium adalah bahan logam yang ringan dan berkekuatan tinggi. Material ini memiliki ketahanan kompresi yang sangat baik, ketahanan terhadap kelelahan, ketahanan terhadap goncangan dan sifat redaman. Karena kemampuannya yang ringan dan kompatibilitas elektromagnetik yang baik, paduan magnesium banyak digunakan dalam bidang penerbangan, otomotif, elektronik, medis dan olahraga.

Saat ini, bahan paduan magnesium yang umum adalah AZ91, AM60, AZ31, WE43, ZE41, dll. Mereka memiliki kekuatan, plastisitas, dan ketahanan korosi yang berbeda, yang dapat memenuhi kebutuhan berbagai bidang.

- AZ91 memiliki kandungan magnesium tertinggi, sekitar 9%, dan memiliki kekuatan dan kekerasan yang tinggi, tetapi ketangguhannya buruk;

- Kandungan magnesium AM60 sedikit lebih rendah, kekuatan dan kekerasannya sedang, dan ketangguhannya lebih baik;

- AZ31 memiliki kandungan magnesium terendah, sekitar 3%, dan kekuatannya lebih lemah, tetapi ketangguhan dan kemampuan mesinnya lebih baik;

- WE43 dan ZE41 adalah paduan magnesium tanah jarang dengan kekuatan tinggi dan kinerja suhu tinggi yang baik;

- Bahan yang berbeda, juga memiliki perbedaan dalam pemrosesan dan pengelasan, dan proses yang sesuai perlu dipilih;

- Ada juga perbedaan dalam penggunaan, seperti AM60 sering digunakan dalam komponen otomotif;

- WE43 dan ZE41 cocok untuk digunakan di lingkungan bersuhu tinggi;

- AZ91 digunakan di bidang kedirgantaraan, dll.

Mulailah Sekarang dengan Die Casting Paduan Magnesium Kustom Sesuai Kebutuhan Anda!

Penerapan Aluminium Die Casting

Selain industri yang terdaftar, paduan magnesium juga dapat digunakan di kapal, kereta api, konstruksi, dan bidang lainnya. Pengecoran paduan magnesium mempromosikan modernisasi industri. Jika Anda memiliki persyaratan khusus, silakan hubungi kami secara langsung.

1. Industri kedirgantaraan

Paduan magnesium adalah bahan logam penting yang digunakan dalam manufaktur kedirgantaraan, seperti pesawat terbang, pesawat terbang, rudal, dll.

2. Industri otomotif

Paduan magnesium banyak digunakan pada kendaraan ringan, yang dapat mengurangi berat kendaraan, meningkatkan efisiensi bahan bakar dan mengurangi emisi karbon dioksida.

3. Produk elektronik:

Paduan magnesium memiliki konduktivitas listrik dan termal yang baik, misalnya, bingkai aluminium paduan magnesium yang biasa digunakan pada ponsel dan komputer tablet.

4. Peralatan olahraga:

Karena kekuatannya yang tinggi, ringan, ketangguhan yang baik dan ketahanan terhadap korosi, magnesium alloy digunakan pada peralatan olahraga seperti stik golf dan sepeda.