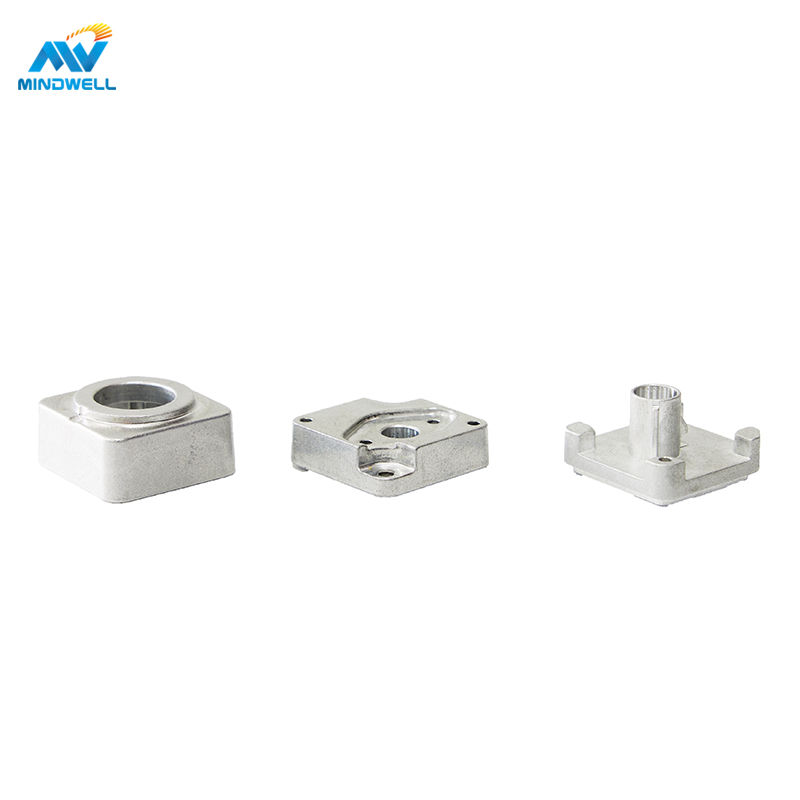

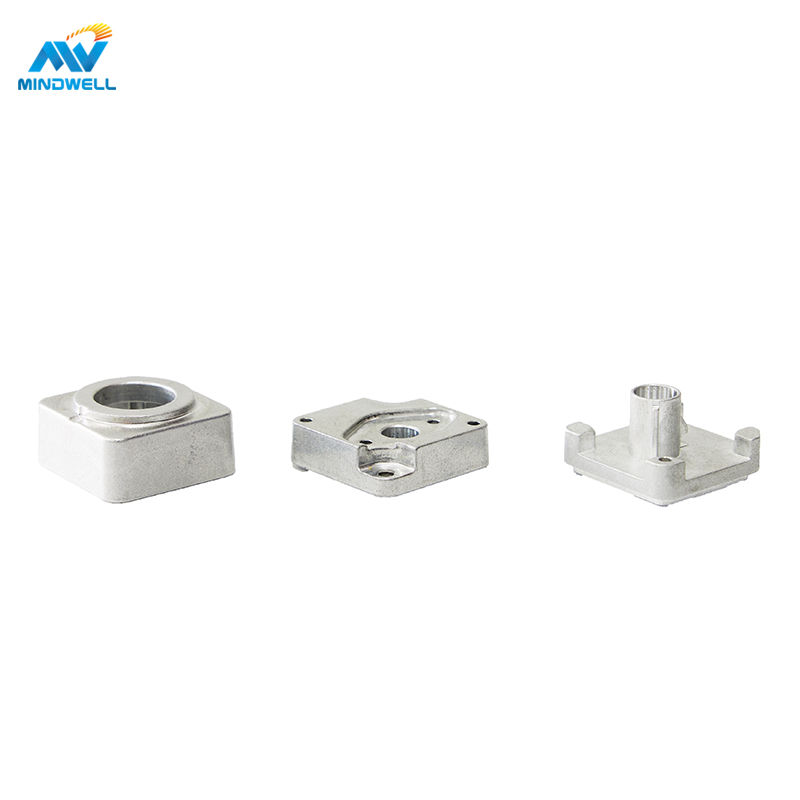

The backup camera housing is the protective housing for the backup camera unit. It is die-cast from lightweight metal materials such as aluminum alloy or magnesium alloy. The strength of the metal material can ensure that the camera maintains stable functions and is not damaged under different weather conditions. Manufacturing rear view camera housing through a die-casting process can achieve efficient, precise and consistent production, and can be produced in large quantities with good strength and durability. Therefore, the die-casting process is widely used in the automotive industry to manufacture various metal casings and parts.

Custom Case Sizes

The shape and size of the backup camera housing of each car are different, depending on the specific camera installation position and style requirements of the car design. Aluminum alloy material is normally used to ensure long-lasting protection of the camera. It can be custom designed according to the mounting bracket or other linkage requirements of the car, so that it can be firmly installed in the use position near the vehicle license plate.

Advantages of our company

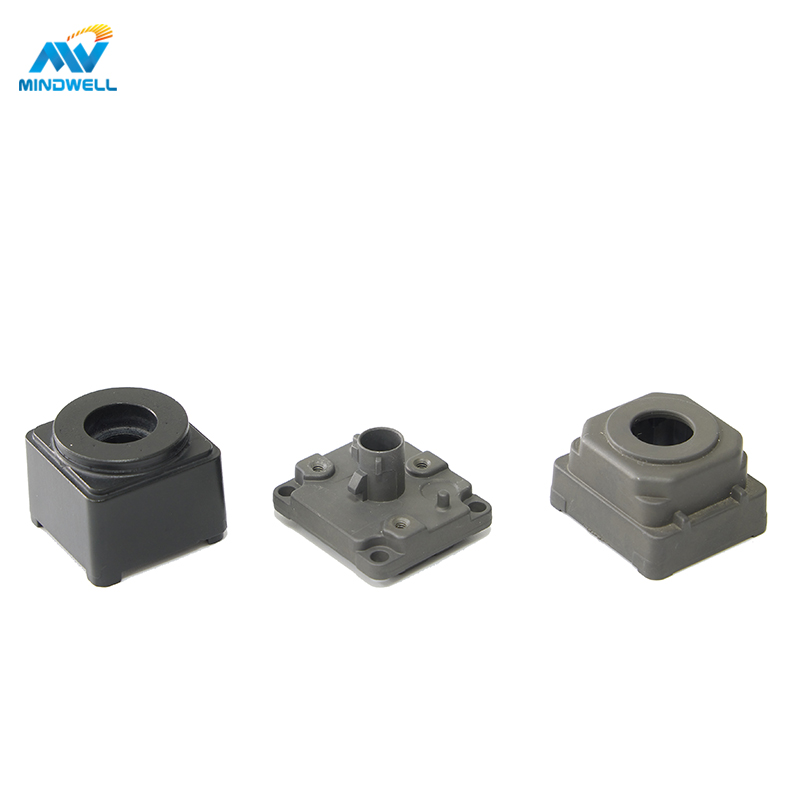

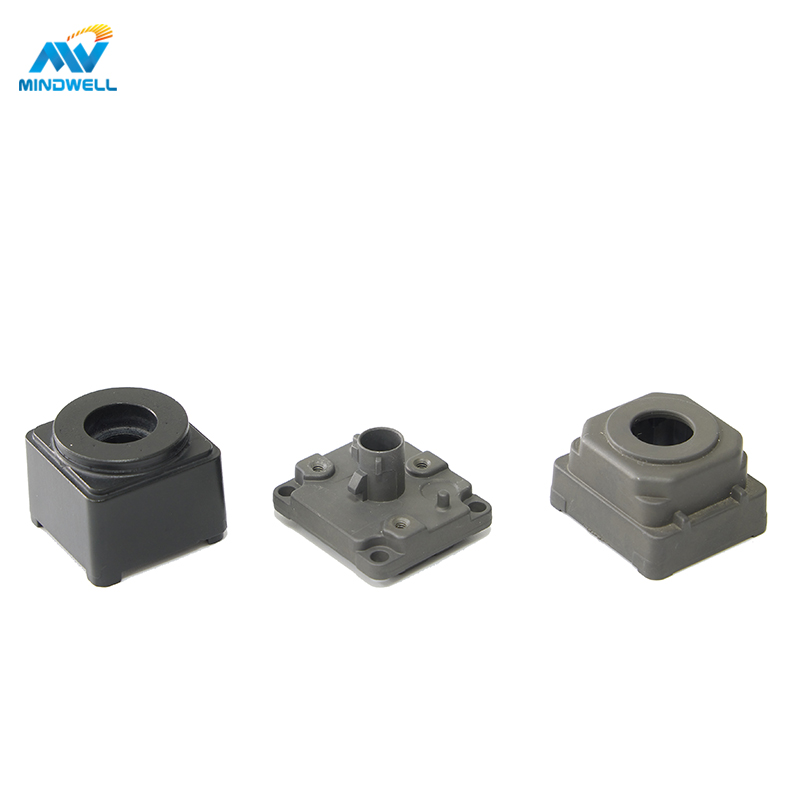

Our company is a professional die-casting company. We provide high-quality, high-precision automotive die-casting parts for the automotive industry. We have customized backup camera housing for Volkswagen and other car companies, as shown in the picture below. Our skilled technicians and engineers ensure that the auto parts we produce meet the highest standards of quality and durability.

In addition to the professional team, we have advanced die-casting equipment, secondary processing equipment and quality testing equipment. According to your customized needs, rear view camera housing can be produced efficiently and in large quantities to achieve high-quality, high-precision auto parts production. If you are a refitting car company or a reversing camera manufacturer and have custom needs for die-casting reversing camera housings, please contact us and we will give you professional advice and quotations.

Application of backup camera housing

Die-casting backup camera housing is an integral part of the reversing camera system applied to the rear of the vehicle. The main function of the housing is to protect the backup camera and its related electronic components to ensure that it works properly and provides clear images.

The reversing camera system is one of the common safety aids in modern cars. By installing a camera at the rear of the vehicle and transmitting the image to the display screen in the car, it can help the driver to observe the situation behind the vehicle more clearly to reduce the risk of reversing. Accidents happen. At present, almost all vehicles are equipped with reversing images. It can mainly provide the following functions:

The role of the aluminum die-casting reversing image housing:

- protect the camera

- Waterproof and dustproof

- Anti-seismic performance:

- Adapt to various vehicle installation environments

In general, the application of the backup camera housing is to protect the camera in the reversing camera system and provide a stable working environment. The aluminum alloy has the characteristics of stability and high strength to ensure that the driver can obtain clear and reliable image information when reversing the car, without shaking or falling of the installation, so as to improve driving safety.

Our Customization Process

Our company has more than ten years of experience in the die-casting industry, especially in the die-casting of auto parts. If you have the needs of customizing auto parts and backup camera housing, welcome to communicate with us. Our custom die casting process flow includes the following steps:

- Demand communication: You can send us the drawings of the auto parts you want to customize. We support basically all drawing formats. After receiving your drawings, the engineer will calculate according to your requirements and parameters, and finally give you a quick quotation. and professional advice.

- Confirmation of production: We will conduct in-depth communication with you on the customized parts to ensure that the produced parts are what you want and meet your use requirements. After confirmation, we will enter the production process.

- Mold Preparation: Create a specific mold that incorporates the geometry and details of the reversing camera housing.

- Molten Metal: Heating a suitable metallic material, such as an aluminum alloy or magnesium alloy, to a molten state.

- Injection into molds: Injecting molten metal into previously prepared molds.

- Cooling and solidification: After the metal is cooled and solidified in the mold, the shell is taken out.

- Trimming and Machining: Trimming of the enclosure, removal of excess material, and necessary machining and surface treatment.

- Inspection and Quality Control: Die-cast housings are inspected to ensure they meet specifications and quality standards.

In our company, we attach great importance to quality inspection and after-sales service, so we have a special quality inspection department equipped with various inspection tools, such as X-ray inspection and so on. And set up a special project team for production projects, with a clear division of labor, and let customers know our production progress at any time.