Servizi di stampaggio a iniezione personalizzati

- Equipment tonnage: 50 to 1300 ton

- Unmanned automated manufacturing

- ISO class 5 clean room function

On-Demand Manufacturing

Our Injection Molding Capabilities

Our advanced injection molding equipment and professional team ensure that we can provide customers with high-performance plastic injection parts, achieving excellent quality, fast delivery and competitive advantage.

Plastic Injection Molding

Our injection molding equipment, including Sumitomo, Demag, Nippon Steel and Haitian, covers a tonnage range from 50 tons to 1300 tons. Customers can customize injection molding services according to their needs,and the price is favorable, so as to achieve excellent quality, fast delivery and price advantage.

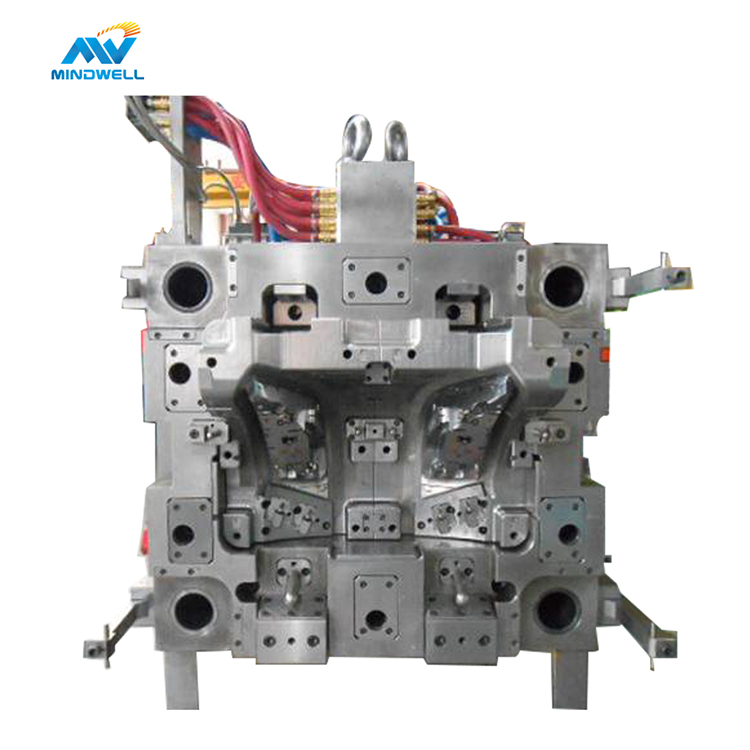

Plastic Injection Mold

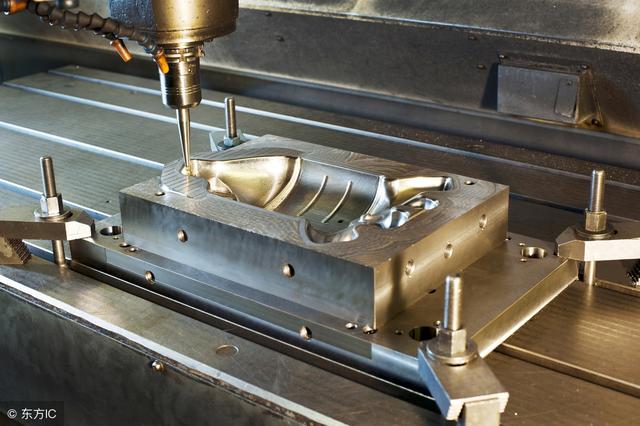

The company has advanced mold making and processing equipment, such as Swiss Charmilles wire cutting machine, Japanese animal husbandry processing center, Japanese animal husbandry spark machine, etc. The maximum mold processing can reach 10 tons, and the processing accuracy can reach 0.005mm

Insert Injection Molding

Insert injection molding is to embed one or several small parts into injection molded parts when manufacturing products. Insert molding has higher production efficiency and lower manufacturing costs, because insert injection molding can complete the entire part in one shot during the injection molding process, combining insert and injection molded parts into a single part.

Overmolding Molding

Molten plastic is applied to the surface of another material by an injection molding machine, creating a single article with two different material properties. Common overmolding materials include ABS, PC, PC/ABS, etc. , this product has excellent physical properties, surface quality and durability. Widely used in automotive, electronics, medical and other industries.

Custom Plastic Injection Molding Materials

According to the size, shape and performance of injection molded parts, we can meet the needs of different industries. We carry out strict quality control in the selection and use of injection molding materials to ensure that the quality of the final product meets the requirements and expectations of customers and can achieve efficient performance.

Mold Materials

Different mold materials can be selected according to different injection molding processes and injection molding materials, and CNC with the highest tolerance is required for precision machining to ensure the accuracy of customized injection molded parts.

The most commonly used materials include:

Tool steel: P20, H13, S7, NAK80, S136, S136H, 718, 718H, 738

Stainless steel:

420, NAK80, S136, 316L, 316, 301, 303, 304

Aluminum: 6061, 5052, 7075

Injection Material

Injection molding service According to the different characteristics of materials, including impact strength, stiffness, heat resistance, chemical resistance, etc., select suitable materials for injection molding services. Commonly used injection molding materials are:

ABS

PVC

PE

PP

PPE

PC

Modified plastics and additives

During injection molding production, standard plastic materials may fall short for custom injection molded parts. For example, if the toughness is not enough, color, etc., additives and fibers can be added to improve aesthetics and functional properties, and provide additional functions for your injection molded parts.

UV absorber

Colorant

flame retardant

glass fiber

plasticizer

Capacità di produzione del servizio di stampaggio a iniezione di MINDWELL

Our injection molding equipment, including Sumitomo, Demag, Nippon Steel and Haitian, covers a tonnage range from 50 tons to 1300 tons. These injection molding equipment adopt the most advanced unmanned automatic manufacturing technology, which can greatly improve production efficiency and quality stability, and reduce labor costs.

Injection molding factory workshop

Our company's injection molding workshop covers an area of 3,000 square meters. We have multiple injection molding machines. Workshop management and lean production mode ensure that we can provide high-quality injection molding parts

Different tonnage injection molding machine

Injection molding machines of different tonnages can provide customized injection molding services with different shapes and sizes. Whether it is large injection molding parts or small injection molding parts, we can design, manufacture and deliver on time according to your design requirements.

Get Started Now with Custom Injection Molding Services According to Your Needs!

Custom Injection Molding Design Guidelines

How does MNW go about the process of a custom injection molding order, from quotation to mass production to final packaging. Our professional technical team, after-sales team and our production department cooperate perfectly to ensure that your molds and custom injection molded parts are delivered to you quickly.

Custom Requirements Communication

Before we start designing injection molded parts, we need a clear understanding of your product requirements. This includes understanding the purpose, shape, size and color of the product. These requirements will help to select the correct material, determine the appropriate mold size and shape, and formulate the correct molding parameters and process flow.

choose the right injection material

Proper selection of injection molding materials is critical. Different materials have a great influence on product performance, molding process and product cost. You need to understand material properties such as heat resistance, chemical resistance, hardness and strength to ensure your products perform as expected while ensuring reliability and efficiency in the molding process.

Mold size and shape

Mold design is a key factor in determining the shape and size of injection molded parts. Our engineers will determine the size and shape of the mold according to the shape and size of the injection molded part, which depends on your product requirements. Proper mold design will ensure stable quality of injection molded parts, mold manufacturing we use CNC machining to ensure machining accuracy up to 0.005mm.

parameters and processes

Parameters such as molding parameters, molding time, injection pressure and injection speed need to be mastered and ensured that they are appropriate. At the same time, we strictly implement the company's production requirements in the process of understanding mold cleaning, filling materials, mold unloading and component quality control.

strict quality control

Injection molding quality control is the key to achieving production quality goals. MindWell has established strict quality control standards, including testing piston positions, verifying product specifications, checking the size and shape of molded parts, and monitoring mold wear. These quality control steps will ensure that your injection molded parts meet expected quality standards

packaging and shipping

We can choose different packaging methods according to customer requirements, including box packing, parts packing separately, etc. Better protection parts will not be damaged during transportation. We support air transportation, sea transportation and railway transportation in terms of transportation methods. We can make reasonable arrangements for these after confirming the order.

Surface Finishes of Injection Molding

We provide surface treatment services for injection molding. The surface treatment factories within three kilometers around the company are not put together with our injection molding workshop because they are related to environmental protection. Everything is for the environment. Appropriate surface treatment can be selected according to the use of injection molded parts.

Surface treatment of injection molded parts can improve the appearance quality and service life of injection molded parts. Common surface treatment methods for injection molded parts include:

- Spraying

- Coating

- Plasma treatment

- Thermal transfer printing

- Lucidatura

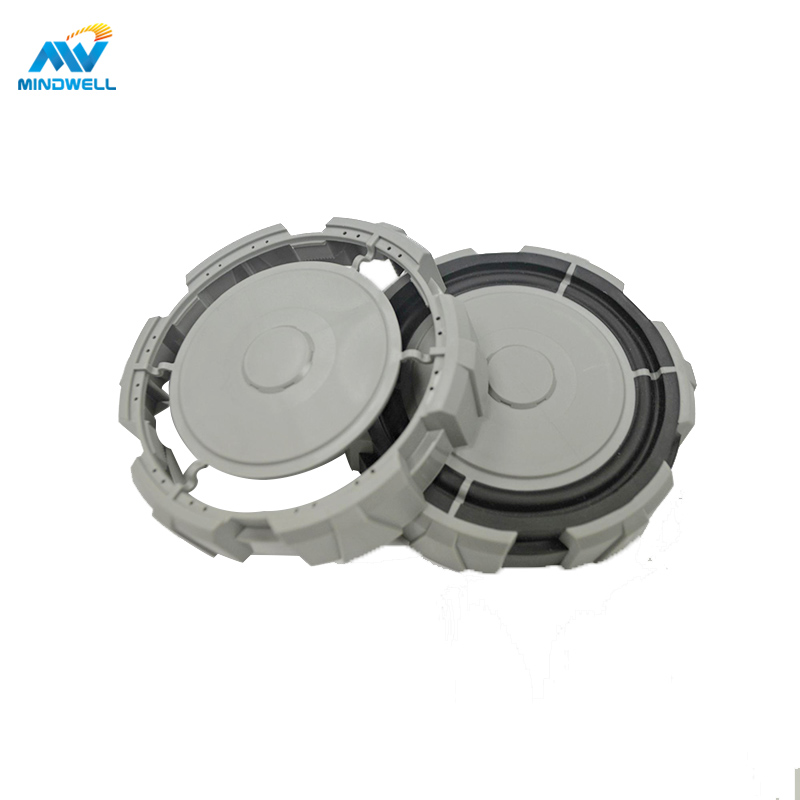

Injection Molded Parts Product Library

The injection molded parts currently displayed are all injection molded products produced by the MNW factory, and they can be displayed after being confirmed by the customer. These parts have been cooperating with the MNW factory for a long time and have established a relationship with friends.

Our Injection Molding Services Applicable to Various Industries

Injection molding is a widely used manufacturing process, MNW company accepts on-demand customization, and our injection molded parts are also widely used in many industries.In addition to these common industries, there are toys, pet supplies, machinery industry, etc.

Industria automobilistica

Automobile injection molding parts are one of the industries that use the most injection molding technology at present. At present, MNW makes more air outlets for air conditioners, car master controls, rearview mirror accessories, gear housings, wiring housings, etc.

Mobili

Injection molding not only improves the quality and reliability of furniture, but also allows for faster and more efficient production of high-volume components. Mainly include: tables, chairs, lampshades and bases of lamps, shells of home appliances, bathroom furniture, home decorations, etc.

Electronic

The injection molding process is widely used in the manufacture of electronic products, which can meet the design needs and market demands of electronic products, and can also reduce costs and improve production efficiency. Including mobile phones, computer casings, internal spare parts, etc.

Machinery

The injection molding process is widely used in the machinery industry, and can be applied to components, mechanical parts, automation equipment and industrial supplies in various machinery industries. These include motor parts, hydraulic parts, instruments and display devices, tools and mold parts

Advantages of choosing MindWell Custom Injection Molding Services

MINDWELL has rich experience in injection molding technology and advanced production equipment, providing customized injection molding services, capable of fast and timely delivery and product quality assurance.

MINDWELL can provide customers with personalized injection molding customization services according to the needs and requirements of customers to meet the needs of different industries and application fields. Choosing MINDWELL has the following 5 advantages:

- Expertise

- Customized service

- Exact match

- Timely delivery

- Garanzia di qualità

Domande frequenti

Injection molding is a technique of making plastic parts by injecting molten plastic into an already prepared injection molding machine, then cooling and solidifying the shape in the mold. This technique is often used in the mass production of plastic products.

Injection molding can use a wide variety of materials such as polyamide, polyethylene terephthalate, polycarbonate, polyethylene, polypropylene, polystyrene, etc. Different materials have different physical and chemical properties, so choosing the right material is very important.

Our company’s Injection Molding services have minimum order quantity requirements. Depends on the size and complexity of the parts required. Generally speaking, the minimum order quantity usually ranges from hundreds to thousands of pieces. If the order quantity is small, we suggest that you can choose our other process methods, such as 3D printing.

The lead time for injection molding depends on the complexity of the part, the type of material, the capacity of the production line, and the number of parts to be produced. After receiving your drawings and production requirements, MNW will contact you quickly to confirm the parameters of the parts, and the engineers will give suggestions and quotations as soon as possible.

Injection molding can minimize environmental pollution with proper management and disposal. Our company chooses to use environmentally friendly materials and production processes to guarantee minimal impact on the environment.

MNW is a reliable custom injection molding service manufacturer, our company has more than ten years of injection molding experience, we have a professional engineer team, and QC department. Our customized parts are also exported to dozens of countries around the world and have won wide acclaim from customers.

Richiedi un preventivo immediato

Richiedete oggi stesso il vostro preventivo gratuito per lo stampaggio a iniezione e vi contatteremo per stabilire una comunicazione.