Servizio di lavorazione CNC

The company has advanced FANUC 4-axis machining center, turning and milling machining center, the company is also equipped with high-precision electric discharge machine, wire cutting machine and other equipment, which can realize high-precision processing of various materials, such as steel, Copper, aluminum, plastic, etc. The machining accuracy can reach 0.005mm.

- High processing precision

- CAD/CAM software customized on demand

- The company passed ISO9001 certification

custom machining services

CNC Turning And Milling

Our company’s CNC turning and milling centers use modern software and technology to increase productivity, reduce labor costs and increase the precision of the final product. Ensuring that MNW can consistently produce high-quality precision parts with tight tolerances is widely used in aerospace, automotive, medical and manufacturing.

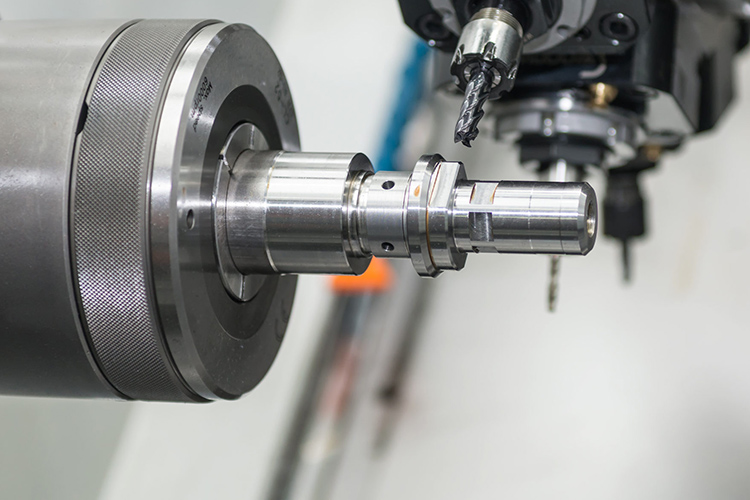

CNC Turning

In turning, a single-point cutting tool is placed parallel to the axis of the workpiece, and the workpiece is rotated relative to it, removing excess material until the desired shape is achieved.

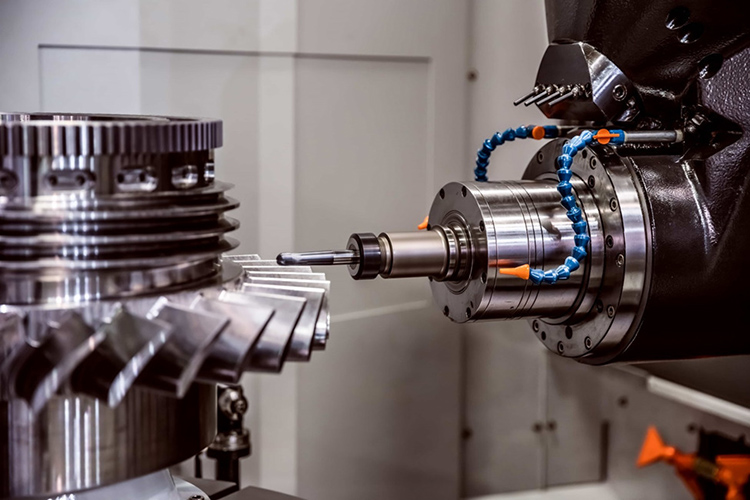

CNC Milling

Milling machines use rotating cutters to remove material from workpieces, forming complex shapes. Ability to perform precise and repetitive movements controlled by a computer.

Materials for Custom CNC Machining Parts

We offer machining in a wide variety of metals and plastics, giving you options for completing rapid prototyping and custom production runs of complex parts.

Alluminio

Aluminum has excellent processing performance, high strength, light weight and corrosion resistance. CNC machining can precisely cut aluminum, producing high-precision, high-quality parts.

Rame

Copper has good electrical and thermal conductivity, so the CNC machining process of copper can achieve very high machining accuracy and machining efficiency.

Brass

Brass can be milled and drilled at high speeds, and copper shavings and swarf generation can be more easily controlled during CNC machining.

Stainless Steel

Stainless steel has good rationality, rigidity and corrosion resistance, and CNC processing technology can perform complex processing on stainless steel workpieces, such as drilling, milling, turning and other processing.

Titanium

Titanium metal requires the use of high-speed cutting tools and advanced processing technology to ensure processing quality and efficiency. Appropriate cutting and tool path control techniques are required for CNC machining.

Plastics

Plastic materials can be processed by CNC machining centers for cutting, milling, drilling, and lettering to produce various complex parts and products. Different plastic materials require different tools and processing parameters in processing

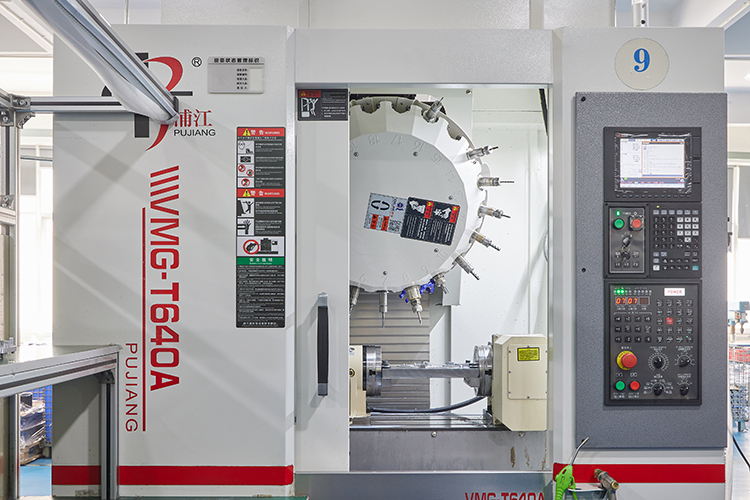

MINDWELL's CNC Machine Capabilities

Our company continuously invests in advanced machinery and equipment to ensure the highest level of precision and quality in our machining processes. Equipped with state-of-the-art technology, our FANUC 4-axis machining centers are capable of handling complex geometries, high volumes and tight tolerances. In addition, our turning and milling machining centers allow us to efficiently produce a wide range of components to meet our customers’ specific needs.

processing workshop

Our team of skilled mechanics undergoes rigorous training and continuous improvement to ensure they operate our machines optimally so that our work is consistent and accurate. We strive to provide precision machining that exceeds our customers' expectations

Equipment Center

We ensure the precision of our machining is always at the forefront of our operations. With machining accuracy of 0.005mm, we can confidently ensure that our components are of the highest quality and meet the strictest standards,ensuring part quality

Get Started Now with Custom CNC Machining Services According to Your Needs!

Surface Finishes for CNC Machining

Trattamento della superficie can make the appearance of CNC parts more beautiful and smooth, and the color stability gives people better visual effects. And can improve corrosion resistance, improve hardness and wear resistance.

MINDWELL provides the following surface treatment services to improve the surface quality of CNC parts and improve the quality of parts.

- 1. Electroplating

- 2. Spraying

- 3. Hard anodizing

- 4. Polished and slippery

- 5. Heat treatment

- 6. Passivation

- 7. Sandblasting

CNC Machined Parts Library

As a professional Chinese CNC machining parts manufacturer, our company provides high quality machined metal parts with high precision and reliable quality. Aluminum, copper, brass and other materials can be selected for processing according to requirements, and are widely used in the fields of auto parts and mechanical parts.

Our CNC Machining for Various Industrial Applications

The CNC machining center is suitable for processing parts that are complex, have many processes, have high requirements, require various types of ordinary machine tools and many tool holders, and can only be processed after multiple clamping and adjustments. The main objects of its processing are box-type parts, complex curved surfaces, special-shaped parts, disc-covered parts and special processing.

Industria automobilistica

In the automobile manufacturing industry, CNC parts are mainly used in the manufacture of key components such as automobile engines, chassis, exhaust systems, braking systems, steering systems, and transmission systems.

Energy Equipment Manufacturing

CNC parts manufacturing technology plays an important role in improving the production efficiency and product quality of energy equipment manufacturing industry due to its high efficiency, high precision and programmable characteristics

Advantages of choosing MindWell Custom CNC Machining Services

MINDWELL has modern equipment and technology and a professional technology and team, which can precisely process various materials, provide high-quality processing services, and ensure high-quality products. And provide a full range of pre-sales, sales and after-sales services to ensure that customers can get satisfactory processed products and services.

Mindwell pays great attention to customer needs and quality, follows high standards of safety and quality requirements, and adopts safe and reliable CNC processing technology to ensure the safety and quality stability of the processing process. The following are the advantages of choosing MINDWELL for CNC machining:

- High quality machined parts

- Good service

- Professional technology and team

- High security

- Cost advantage

Domande frequenti

A CNC machining service is a high-tech manufacturing service that uses computer numerical control technology and precision machines to cut and machine parts, molds or mechanical parts. It can make parts of any shape or size, either as a single piece or in high-volume production.

The file formats used by our engineers are supported: .dwg, .dxf, .iges, .step, .stl, etc.

Timing depends on the size and complexity of the project. Generally, simple designs can be completed in a few hours, while complex designs can take days or longer to complete.

Materials include: non-ferrous metals, plastics and other materials. Different materials are suitable for different projects and budgets, common CNC machining materials are aluminum, copper, brass, titanium, plastic, stainless steel, etc.

We have a dedicated QC department that will continue to track product quality and communicate with customers to ensure that the project meets all requirements during production to ensure the final product quality.

We will take various measures, such as reasonable packaging design, appropriate marking and labeling, etc. We work hard to ensure that the product you receive is undamaged.

We are committed to protecting our clients’ intellectual property and business secrets from unauthorized disclosure. Also, a confidentiality agreement will be signed before signing a formal contract.

Richiedi un preventivo immediato

Richiedete oggi stesso il vostro preventivo gratuito per lo stampaggio a iniezione e vi contatteremo per stabilire una comunicazione.