Industrial Equipment and Machinery Parts

The parts we produce are also widely used in industrial equipment parts. Industrial equipment parts are an indispensable part of industrial production. Their quality, reliability and performance directly affect the stability and work efficiency of equipment.

- Various processing techniques are optional

- Fast Quote Fast Delivery

- 7/24 hours team service

Produzione su richiesta

Industrial Equipment and Machinery spare parts Manufacturing

The manufacturing of mechanical equipment spare parts usually uses precise manufacturing processes. Mindwell has the ability to produce precision. We provide different manufacturing processes, from material control to mold design and manufacturing to quality control. We strictly control and provide Provide professional services to customers.

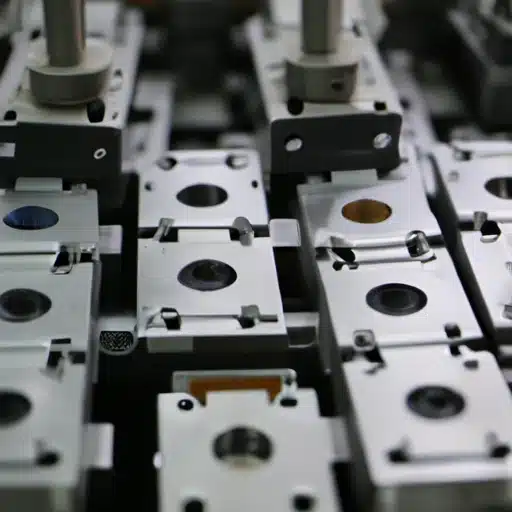

Plastic Injection Molding

Injection molding has the advantages of high accuracy, high production efficiency, and high product yield, and can produce products of various complex shapes.

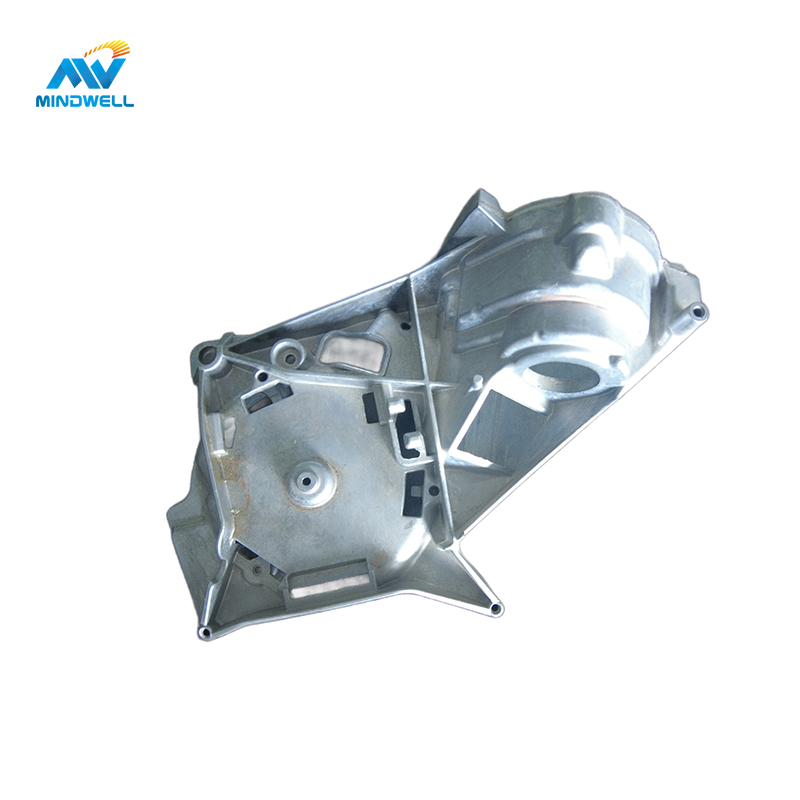

Pressofusione

We use die casting, sand casting, casting, gravity casting and other processes in the production of large and complex mechanical parts

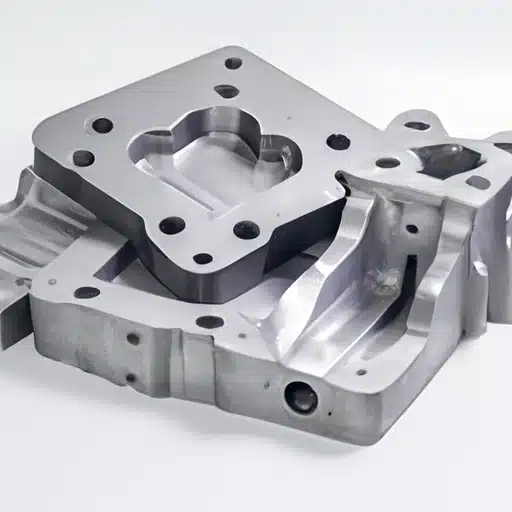

Lavorazione CNC

We use CNC machining technology when processing some mechanical parts that require high precision and high efficiency, including CNC turning and CNC milling .

Stamping Parts

Stamping is suitable for high-volume production because of the high productivity of the stamping process. Able to deliver quickly

MindWell Prototyping & Production Solutions for Industrial Equipment and Machinery Industry

Industrial equipment parts processing includes processing various parts such as mechanical parts, electronic components, and mechanical structural parts. MindWell has die-casting, injection molding, CNC and other processing equipment and advanced technology

stampaggio a iniezione

MindWell has 50-1300 tons of injection molding machines, which can manufacture parts of various shapes and sizes.

Lavorazione CNC

CNC machining of industrial equipment parts is an efficient, precise and repeatable manufacturing technique that can meet the needs of various industries.

Get Started Now with Custom Industrial Spare Parts According to Your Needs!

Custom Parts for Industrial Applications

Mechanical parts refer to elements used in mechanical structures. Common mechanical parts include fasteners, transmission components, seals, elastic components, etc. These parts are widely used in machine tools, automobiles, airplanes, ships and other mechanical equipment.

MindWell offre la produzione personalizzata di vari componenti per auto. Le applicazioni automobilistiche più comuni che realizziamo includono:

1. Fasteners

Fasteners refer to bolts, screws, nuts, etc. used to connect and fix various parts

2. Transmission parts

Transmission parts refer to various parts used to transmit power, such as gears, shafts, couplings, etc.

3. Seals

Seals refer to various parts used to seal the machine structure, such as O-rings, oil seals, gaskets, etc.

4. Elastic parts

Springs, washers, shock absorbers, etc. are all elastic parts

5. Moving parts

Moving parts are parts used to generate motion in mechanical equipment, including cams, cranks, connecting rods, etc.

About Our Company

MindWell pays attention to technological improvement and personnel training, adopts advanced CAD/CAM/CAE technology as the core, optimizes design, manufacture and processing of molds, and has passed ISO 9001 quality management system certification. The company has introduced a sophisticated CNC machining center, supporting advanced EDM, wire cutting and conventional machining equipment. And excellent talents, advanced technology and equipment have greatly improved the precision and speed of mold making. The company also has six cold chamber die-casting machines (1250T, 800T, 550T, 400T, 280T, 200T) and machining centers, CNC lathes, vibration finishing machines, shot blasting machines and other post-processing equipment for castings, outsourced processing and spraying, Electrophoresis, electroplating, baking varnish and other surface treatments can directly provide customers with one-stop production line services from mold design to finished products, and provide high-quality die-casting products.

Richiedi un preventivo immediato

Richiedete oggi stesso il vostro preventivo gratuito per lo stampaggio a iniezione e vi contatteremo per stabilire una comunicazione.