LED照明製造におけるアルミダイカストの役割

アルミダイカストは、LED電球の製造において重要な役割を果たしており、主にLEDランプのランプホルダー、シェル、ラジエーターなどの部品に使用されています。アルミダイカストの利点は、材料が強く、軽量で硬いことです。ランプの品質要求を満たすと同時に、重量を最大限に軽減し、ランプをより安全で信頼性の高いものにします。さらに、アルミニウムは放熱性にも優れており、LED電球は長期的な安定性と信頼性を維持するために、通常、優れた放熱性を必要とします。そのため、電球から発生する熱を逃がすために、LED電球のハウジングとして使用されています。

つまり、当社はアルミ合金ダイカストでアルミケーシングを製造しています。製造工程が比較的簡単で、短時間で効率よく生産できるため、生産コストを抑えることができます。一般的には、放熱機能を高めるために内部回路基板の後ろにアルミ放熱板を設置し、固定設置を容易にするために外側にブラケットを追加します。ダイキャストシェルの表面処理は、一般的に屋外で溶射され、ポリエステル溶射のものもあれば、フッ素溶射のものもある。カーボンスプレー、特別な保護条件の屋外パウダー。

つまり、アルミダイカストはLED電球の製造において、主に放熱、熱伝導、軽量、防錆の役割を担っている。

アルミニウム合金ダイカスト付属品を照明産業に応用する利点

軽量

アルミ合金の密度は、鋼や他の材料より小さい。アルミ合金のダイキャストアクセサリーを使用すると、ランプの重量を減らすことができ、輸送や設置が容易になります。

高い熱伝導性

アルミニウム合金は熱伝導率が高く、LEDランプビーズから発生する熱を素早く放散し、LEDランプの寿命を延ばす。

加工しやすい

アルミニウム合金は可塑性に優れ、さまざまな形状に加工しやすいため、さまざまな形状のLEDランプを容易に製造できる。

低コスト

アルミ合金は比較的手頃な価格で一般ユーザーにも受け入れられるため、LEDランプのコスト削減に役立つ。

酸化防止

アルミニウムの表面には酸化アルミニウムの緻密な層があり、酸化や腐食を防ぐのに効果的で、製造されたLEDランプの耐久性を保証する。

要約すると、アルミニウム合金ダイカスト付属品は照明業界において、装置の放熱性能を向上させ、装置の重量を軽減し、装置の美観を向上させるなど、幅広い応用の見込みがある。Mindwell会社は高品質のダイカスト金型とアルミ合金製品を提供する専門メーカーです。高品質な製品、先進的な技術、優れたサービスで業界から高い評価を得ています。

LED電球ヒートシンク

放熱性能はLED電球の設計において非常に重要である。なぜなら、LEDチップは動作時に一定量の熱を発生するからである。放熱性能が低いと、LEDチップの温度が高くなりすぎ、LED電球の寿命や性能に影響を与える。

アルミダイキャストがLED電球の放熱性能を向上させる理由

- アルミニウムは熱伝導性と放熱性に優れているため、アルミダイカストはLED電球において重要な役割を果たしています。ここでは、アルミダイカストがLED電球の熱性能をどのように向上させるかについて、いくつかの重要な側面をご紹介します:

- 放熱方法:一般的に、自然放熱と強制空冷の2種類があり、それぞれの使用環境や要求に応じて選択する必要がある。

- 放熱構造の最適化:アルミダイキャストにより、複雑なヒートシンクとフィンを持つ放熱構造を設計し、放熱表面積を増加させることで、放熱効率を向上させることができます。これにより、LEDバルブの温度を低く抑えることができます。

- 材料の安定性:アルミニウム合金は熱伝導性に優れ、LEDから発生する熱を素早く伝えることができる。これにより、熱を電球の外面に分散させ、LED素子の周囲に熱がこもるのを防ぎます。また、アルミニウム合金材料は、異なる温度でも安定性を保つことができ、変形や膨張を起こしにくい。このため、LEDバルブは長期間の使用においても、温度変化による性能の問題を生じることなく、構造的な安定性を維持することができる。

要旨:LED電球の設計過程において、アルミダイカストはLED電球の放熱性能に重要な役割を果たし、LED電球の熱管理上の課題を解決し、LEDの寿命を延ばし、性能と信頼性を向上させるのに役立ちます。Mindwellでは、LED電球が優れた放熱性能を持つように、シミュレーション実験などを通じて調整と最適化も行っています。

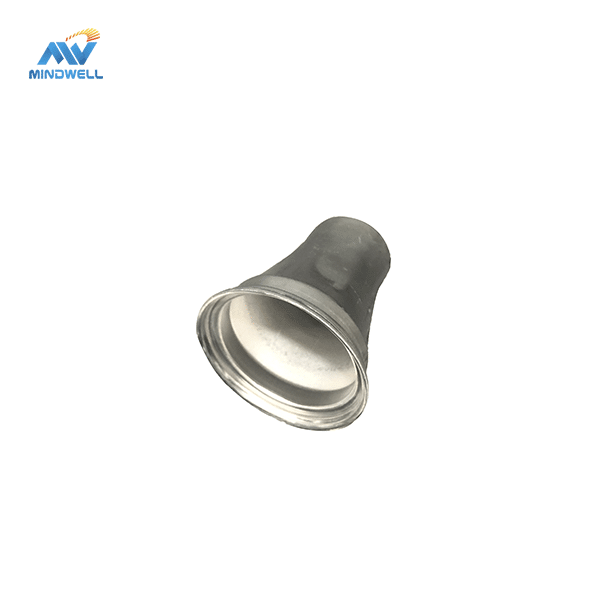

導かれた球根アルミニウム ハウジング

導かれた球根アルミニウム ハウジングは LED の球根の構造の重要な部分です。導かれた球根アルミニウム ハウジングにライト級選手、高力および高い安定性の特徴があります。それは LED の部品を保護し、球根の安定性を保障できます。LED の球根アルミニウム ハウジングは LED の照明解決の長寿、性能および審美性を改善するのを助けます。

LED電球の固定設置

アルミダイカストは、LED電球に強力な構造支持を提供し、LED部品の適切な設置と長期的な安定性を確保するために不可欠です。ここでは、アルミダイカストが構造支持にどのような役割を果たしているかをご紹介します:

- 頑丈で安定している

- 耐振動性と耐衝撃性

- 強度と軽量性

- 耐食性

要約すると、アルミダイカストは構造的な支えを提供し、アルミの強度と安定性はLED部品の長期的な安定設置に役立ち、LED電球がさまざまな環境でその性能と信頼性を維持することを可能にします。これは、顧客のニーズと期待に応えるために不可欠です。

アルミダイカストには持続可能性と環境面での利点がある

リサイクル性

アルミニウムはリサイクル性の高い金属であるため、アルミダイカストのスクラップは溶かして形を変え、再び新しいダイカスト製品に使用することができます。このリサイクルプロセスは、原材料を節約するだけでなく、廃棄物による環境汚染も軽減します。

材料の無駄を省く

アルミダイカストの工程では、ダイカストの特性上、材料の使用量を正確にコントロールすることができ、生産工程での無駄を省くことができます。アルミダイカストは、他の金属加工法よりも材料を効率的に利用するため、材料の無駄が少なくなります。

省エネとカーボンフットプリント削減のメリット

アルミダイカストは、他の金属加工方法よりも効率的で、エネルギー消費を削減することができます。同時に、アルミの軽量特性により、アルミダイカストを使用することで製品の重量を減らすことができ、輸送や使用時のエネルギー消費を削減し、カーボンフットプリントの削減に貢献します。

アルミダイカストは、アルミニウムのリサイクル性、材料廃棄物の削減、エネルギー消費量とカーボンフットプリントの削減など、複数の持続可能性と環境上の利点を提供します。このため、環境保護と持続可能な開発の原則に沿った、環境に優しい製造方法となっています。

LED電球用アルミダイカスト:イルミネーションイノベーション

LED電球用アルミダイカストの変革的役割をご覧ください。精度工学、耐久性、カスタマイズ・オプションの詳細をご覧ください。この包括的な アルミダイキャストガイド LED電球用。

1.アルミダイカストの起源

アルミダイカストの歴史は19世紀まで遡ることができる。重要な製造方法として、アルミダイカストはLED電球などの分野で重要な役割を果たしています。精密工学の設計と生産を通じて、アルミダイキャストプロセスは、複雑な形状と微細な構造を持つ部品を作成することができ、光の方向と分布を正確に制御して、LED電球の最高の性能を達成することができます。今後、技術の絶え間ない進歩とアプリケーションの要求の増加により、アルミダイキャストプロセスはますます発展し、革新し続け、製造業の発展に大きく貢献することでしょう。その詳細な発展プロセスについては、次のような側面から探ることができる:

- アルミダイカスト技術の原点19世紀後半、産業革命の進展と製造技術の絶え間ない発展に伴い、ダイカスト技術が徐々に人々の注目を集めるようになった。当初のダイカスト技術は、主に鉛型などの小型で単純な金属部品を製造するために使用されていました。この時期のダイカストマシンは主に手動のピストン式ホットチャンバーダイカストマシンであり、その生産効率と精度は比較的低かった。

- 20世紀に入ってから、ダイカスト技術はさらに発展し、利用されるようになった。1905年、H.H.デーラーは工業生産用のダイカストマシンの開発に成功した。この発明は、ダイカスト技術が大規模で高効率の生産能力を持つことを示した。製造技術の継続的な進歩に伴い、ダイカスト工程の生産効率と品質も向上し続けています。

- アルミダイカスト技術の発展20世紀前半、アルミダイカスト技術は徐々に発展し、応用されるようになった。アルミニウムの軽さと優れた導電性により、アルミニウムダイカストは電子、電気などの分野で広く使用されています。技術の絶え間ない進歩と応用により、アルミダイカスト工程はさらに改善され、革新されてきました。現代のアルミダイカスト工程は、複雑な形状や微細な構造を持つアルミダイカスト部品を生産することができ、その生産効率と製品品質は大幅に向上しています。

- アルミダイカスト技術のLED電球への応用LED電球の生産において、アルミダイカスト技術は内部の高精度部品の製造に広く使用されている。これらの部品は、LED電球の発光効率と寿命を向上させる上で重要な役割を果たしている。精密工学の設計と生産を通じて、アルミダイキャストプロセスは、複雑な形状と微細な構造を持つ部品を作成することができ、LED電球の最高の性能を達成するために、光の方向と分布を正確に制御することができます。

2.LED電球にアルミダイカストの利点が現れる

LED電球におけるアルミダイカストの利点は、主に高い熱効率、長い耐用年数、軽量性と耐久性、設計の柔軟性に反映されています。これらの利点により、アルミダイカストプロセスはLED照明の分野で幅広い応用の見通しと市場の可能性を持っています。以下では、LED電球におけるアルミダイカスト部品の利点を詳しく紹介する:

1.高い熱効率

アルミニウムは熱伝導性に優れているため、アルミダイカストはLED電球の熱を効果的に伝導・放熱することができます。LED電球は作動時に大量の熱を発生します。この熱を効果的に放熱できないと、LEDチップの温度が上昇し、発光効率や寿命に影響を及ぼします。アルミダイキャストの高い熱伝導率は、LED電球が動作中に適切な温度を維持し、過熱による性能低下や寿命の短縮を確実に防ぐことができます。

2.長い耐用年数

アルミダイカスト部品は放熱性能が良いだけでなく、耐食性、耐摩耗性も高いため、LED電球の安定した使用状態を長期間維持し、LED電球の寿命を延ばすことができます。同時に、アルミダイカスト部品の高精度製造と安定した寸法精度も、長期使用中のLED電球の安定性と信頼性を保証します。

3.軽量で耐久性がある。

アルミニウムの密度が低く軽量であるため、アルミニウムダイカストはLED電球の軽量化を実現します。同時に、アルミダイカスト部品は高い強度と優れた靭性を持ち、外力による衝撃や振動に耐えることができるため、過酷な環境でもLED電球の正常な動作を保証します。この軽量性と耐久性により、アルミダイカストはLED照明ソリューションの全体的な効率向上とエネルギー消費の削減に貢献します。

4.設計の柔軟性

アルミダイキャストプロセスは、複雑な形状や微細な構造の製造を実現することができ、LED電球のデザインに多くの可能性を提供します。デザイナーは想像力をフルに発揮し、様々な顧客のニーズを満たすために、様々なユニークで美しいLED電球の形状を作成することができます。同時に、アルミダイカストの高精度な製造は、LED電球の光学性能と使用効果を保証します。

3.LED照明アプリケーション

アルミダイカストは、LED照明アプリケーションにおいて重要な役割を果たしており、その用途はLEDアセンブリ内のハウジングから複雑な部品まで多岐にわたります。この多様性と適応性により、さまざまな異なる環境でLED電球の効率的で安定した性能が保証されます。以下は、LED照明におけるアルミダイカストの主な用途の一部です:

ハウジングとヒートシンク

放熱効果:アルミダイキャストハウジングとラジエーターは、その高い熱伝導率を利用して、LEDチップから発生する熱を効果的に周囲に伝導・放熱し、過熱を防ぎ、LED電球の安定性と長寿命を確保します。

軽量で丈夫:アルミニウムの軽量特性により、十分な強度と耐久性を維持しながら、LED照明器具をより軽く、設置や持ち運びが容易になります。

反射鏡と光学部品

精密な光制御:アルミダイカストは、光の方向と分布を正確に制御し、光効率と照明品質を向上させるために、複雑な反射鏡とレンズを製造することができます。

耐食性:アルミダイカストは耐食性に優れ、湿潤環境や腐食環境でも安定した光学性能を維持できる。

回路基板および電子部品ホルダー

電気的特性:アルミニウムの優れた電気伝導性は、回路基板や電子部品サポートに理想的な材料であり、電気のスムーズな流れを保証します。

正確な位置決め:アルミダイキャストプロセスの高精度は、電子部品の正確な位置とインストールを保証し、LED電球の全体的なパフォーマンスを向上させます。

コネクターと固定具

安定性:アルミダイキャスト製のコネクターと固定具が強力なサポートと安定性を提供し、振動や衝撃環境下でもLED電球が正常に動作することを保証します。

加工のしやすさ:アルミニウムは加工が容易なため、コネクターや固定具を他の部品と簡単に組み立てることができ、生産効率が向上します。

クリエイティブなデザインとカスタマイズ

設計の柔軟性:アルミダイキャストプロセスの高い柔軟性により、設計者は市場や消費者の多様なニーズを満たすために、様々なユニークでカスタマイズされたLED電球を作成することができます。

コスト管理:アルミダイキャストプロセスは、低コストを維持しながら大規模生産を可能にし、高品質のLED照明製品をより身近なものにします。

全体的に、LED照明の用途におけるアルミダイカストの多様性と適応性は、さまざまな環境におけるLED電球の高効率と安定した性能を保証します。技術の継続的な進歩と市場の需要の拡大により、LED照明分野におけるアルミダイカスト部品の応用は、より広範かつ深化していくでしょう。

4.生産工程

LED電球のアルミダイキャスト部品の製造は、最終製品の品質と性能にとって各工程が非常に重要な、多工程で非常に繊細なプロセスです。以下は、製造工程の主なステップです:

金型の設計と製造:

設計する:LED電球の仕様と要件に応じて、CADソフトウェアを使用して金型を設計します。

材料の選択:金型の耐久性と精度を確保するため、アルミダイカストに適した金型材料、通常は高硬度鋼を選択する。

加工:CNC工作機械やその他の高精度機器を使用して金型を加工し、金型の精度と表面品質を確保する。

アルミダイカスト製造:

製錬:アルミニウム地金は融点まで加熱され、製錬の過程で不純物が取り除かれる。

射出:予熱された金型にアルミニウム溶湯を高圧で注入し、アルミニウム液が金型キャビティを完全に満たすようにします。

冷却と凝固:溶融アルミニウムを金型内で冷却固化させ、所望の部品形状を形成すること。

脱型:金型を開き、凝固したアルミダイカストを取り出す。

後処理と仕上げ:

トリミング:ダイカスト部品の縁からバリや余分な材料を取り除くこと。

Heat treatment: The mechanical properties of aluminum die castings are further improved through the heat treatment process.

Surface treatment: Carry out surface treatments such as spraying and electroplating to improve the corrosion resistance and aesthetics of parts.

Inspection and QC:

Dimensional inspection: Use measuring tools to conduct dimensional inspection of aluminum die castings to ensure they meet design requirements.

Performance testing: Perform pressure testing, tensile testing, etc. to verify the performance indicators of aluminum die castings.

Appearance inspection: Check the surface quality of the product to ensure that it is free of defects and imperfections.

5. Customization options

The high flexibility of the aluminum die-casting process provides LED light bulb manufacturers with a wealth of customization options. These options not only meet the needs of the market and consumers for unique designs and functions, but also help manufacturers stand out in the highly competitive LED market. Here are some highlights among the customization options:

- Shape and size customization: Manufacturers can customize the shape and size of LED light bulbs based on customer needs or specific application scenarios. Whether it is a traditional spherical shape, a tube shape, or a more creative special-shaped design, the aluminum die-casting process can all be achieved.

- Optimization of heat dissipation structure: In response to the heat dissipation requirements of LED light bulbs, manufacturers can customize the structure and size of the radiator to ensure that the LED chip can effectively dissipate heat under different working environments, thus extending product life.

- Optical performance adjustment: By adjusting the shape and surface treatment of optical components such as reflectors and lenses, manufacturers can customize the light distribution and efficacy of LED bulbs to meet different lighting needs.

- Personalized surface treatment: The surface treatment of aluminum die-casting parts can also be customized, including color, texture, coating, etc. This provides LED light bulb manufacturers with more design freedom to create more attractive product appearances.

6. Quality Assurance: Demonstrate Reliability

In the production process of LED bulbs, quality assurance measures are a key link in ensuring product reliability and stable performance. Here are several important quality assurance measures:

- Non-destructive testing: Use non-destructive testing technologies such as X-ray and ultrasonic waves to detect internal defects in aluminum die-casting parts to ensure that there are no pores, cracks and other problems inside the product.

- Dimensional accuracy control: Through advanced measuring equipment and strict inspection processes, we control the dimensional accuracy of aluminum die castings to ensure that each part meets the design requirements.

- Environmental adaptability test: Conduct high-temperature, low-temperature, humidity-heat and other environmental adaptability tests on LED light bulbs to verify the product’s working stability and reliability in different environments.

7. Sustainability in LED manufacturing

With the increasing awareness of environmental protection, LED manufacturing industry is also paying more and more attention to sustainable development. The aluminum die-casting process plays an active role in this regard:

- Resource recycling: Aluminum is a highly recyclable material. Used aluminum die-casting parts can be recycled and reused, reducing the demand and exploitation of primary resources.

- Reduce energy consumption: By optimizing production processes and upgrading equipment, we can reduce energy consumption during the aluminum die-casting process and improve energy utilization efficiency.

- Reduce waste emissions: Implement a strict waste management system to reduce solid waste emissions during the production process, and reasonably classify and process waste.

- Use environmentally friendly materials: Environmentally friendly coatings, solvents and other auxiliary materials are used in the aluminum die-casting process to reduce harmful emissions to the environment.

How does Aluminum Die Casting enhance the performance of LED bulbs?

LED light bulbs are becoming more and more popular due to their high energy efficiency and long lifespan. A key factor that affects the overall performance of an LED bulb is the materials used in its construction. Die-cast aluminum, in particular, has become the first choice among LED bulb manufacturers. In this article, we’ll explore the reasons for using die-cast aluminum and how it can improve the performance of LED bulbs.

1. Heat dissipation

One of the main advantages of using die-cast aluminum in LED bulbs is its excellent heat dissipation properties. LED bulbs will generate heat during operation. If they cannot be effectively dissipated, it will lead to reduced performance and shortened life. Die-cast aluminum has high thermal conductivity, allowing it to effectively transfer heat away from the LED component. This ensures the LEDs remain cool, preventing overheating and maintaining optimal performance.

2. Durability and Protection

Die-cast aluminum provides exceptional durability and protection for precision LED components. Its rugged characteristics make it resistant to shock, vibration and external environmental factors. This is especially important for LED light bulbs used outdoors or in industrial settings, where they may be exposed to harsh conditions. The die-cast aluminum housing acts as a protective shield, protecting the internal components from damage and extending the life of the LED bulb.

3. Lightweight and compact design

Die-cast aluminum is known for its lightweight yet strong properties, making it an ideal material for LED light bulb construction. Its light weight makes installation easier and reduces stress on fixtures. In addition, the compact design achieved through die-casting allows LED bulbs to be installed into a variety of lighting fixtures, including recessed lighting, track lighting, and decorative fixtures. This versatility ensures that LED bulbs can be integrated seamlessly into different environments without compromising performance.

4. Corrosion resistance

LED light bulbs can be exposed to moisture and other corrosive elements, especially outdoors or in humid areas. Die-cast aluminum is highly corrosion-resistant, making it an excellent choice for this type of application. The corrosion-resistant nature of die-cast aluminum ensures that LED bulbs are protected and maintain their performance even in challenging environments.

5. Design flexibility

Die-cast aluminum allows for complex designs, giving manufacturers greater flexibility in creating LED light bulbs with innovative features. The versatility of die-casting allows various components, such as heat sinks and optics, to be integrated into the bulb’s structure. This results in improved light distribution, better color rendering, and enhanced overall performance of the LED bulbs.

おわりに

Die-cast aluminum plays a vital role in enhancing the performance of LED bulbs. Its excellent thermal performance, durability, lightweight design, corrosion resistance and design flexibility make it an ideal material for LED bulb construction. By using die-cast aluminum, manufacturers can ensure optimal performance, longer service life of LED bulbs, and provide efficient lighting solutions for a variety of applications.

Can Aluminum Die Casting be applied to various types of LED bulb designs?

Yes, aluminum die-casting can be applied to various types of LED light bulb designs.

Aluminum die-casting is a manufacturing process that uses aluminum metal as raw material. The aluminum is melted and injected into the mold through a die-casting machine, and then cooled and solidified into the required shape. This process can create a variety of complex shapes and structures, so it can be applied to various types of LED light bulb designs.

For example, the shell, radiator, bracket, etc. of LED bulbs can be manufactured using aluminum die-casting. Through reasonable mold design and processing technology, LED bulb casings with excellent heat dissipation performance, high strength, high precision, and beautiful appearance can be produced.

In addition, the aluminum die-casting process can also be combined with other manufacturing processes, such as injection molding, spraying, etc., to create more complex and diversified LED bulb products.

In summary, aluminum die-casting is a manufacturing process that is well suited to be applied to various types of LED bulb designs.

What role does thermal efficiency play in Aluminum Die Casting for LED bulbs?

Thermal efficiency plays an important role in aluminum die castings for LED light bulbs.

First, thermal efficiency directly affects the performance and life of LED bulbs. LED chips generate heat when working. If the heat is not properly controlled, the performance of the LED chip will decrease or even be damaged. Therefore, improving the thermal efficiency of aluminum die castings can effectively dissipate the heat generated by LED chips and maintain the stability and life of LED bulbs.

Secondly, thermal efficiency also affects the energy-saving effect of LED light bulbs. If the thermal efficiency of aluminum die castings is low, the LED bulb will generate more heat when working and require more energy to maintain work, which will increase energy consumption and operating costs. Therefore, improving the thermal efficiency of aluminum die-casting parts can reduce the energy consumption of LED light bulbs and improve energy-saving effects.

To sum up, thermal efficiency plays an important role in LED bulb aluminum die castings, which directly affects the performance, life and energy-saving effect of LED bulbs. Therefore, when designing and manufacturing LED light bulb aluminum die castings, thermal efficiency factors need to be fully considered to improve product performance and reduce energy consumption.

Is the lightweight nature of aluminum beneficial for LED bulb manufacturing?

When it comes to LED bulb manufacturing, material selection plays a vital role in determining the performance, efficiency, and overall quality of the final product. One material that has attracted a lot of attention in recent years is aluminum, mainly due to its lightweight properties and the numerous advantages it offers during manufacturing. In this article, we’ll look at why aluminum’s lightweight properties are beneficial in the manufacturing of LED light bulbs.

1. Energy efficiency

LED light bulbs are known for their excellent energy efficiency, and aluminum’s lightweight properties contribute to this. Aluminum is a lightweight metal that can better dissipate heat, reducing the risk of overheating and increasing the overall energy efficiency of LED bulbs. By efficiently dissipating heat, aluminum helps extend the life of the LED chip, ensuring the bulb maintains brightness and performance for longer.

2. Design flexibility

Aluminum’s lightweight nature gives manufacturers greater design flexibility in the production of LED bulbs. Aluminum’s malleability allows it to be easily formed into intricate shapes, enabling the creation of innovative and beautiful LED light bulb designs. This flexibility also extends to the integration of additional features such as heat sinks, which are essential to maintaining optimal operating temperatures.

3. Easy to install

Another advantage of aluminum being lightweight is its ease of installation. LED light bulbs made of aluminum are much lighter than those made of other materials, making them easier to handle and install. This lightweight feature is particularly useful where large numbers of LED bulbs need to be installed, such as in commercial or industrial settings.

4. Durability

Despite its light weight, aluminum is a highly durable material. Made of aluminum, LED bulbs are resistant to corrosion, ensuring their longevity even in harsh environments. This kind of durability is critical for LED bulbs, which can be exposed to moisture, dust, or other factors that can affect their performance. By using aluminum, manufacturers can create LED light bulbs that are not only lightweight but also strong and durable.

5. Environmentally friendly

Aluminum is known for its recyclability, making it an eco-friendly choice for LED light bulb manufacturing. Aluminum’s lightweight nature reduces overall material consumption, allowing for a more sustainable manufacturing process. Additionally, aluminum can be easily recycled without losing its inherent properties, further reducing the environmental impact associated with the production of LED light bulbs.

おわりに

Aluminum’s lightweight nature provides numerous advantages for LED bulb manufacturing. From improved energy efficiency and design flexibility to ease of installation, durability and environmental friendliness, aluminum is proving to be an excellent choice for manufacturers looking to produce high-quality LED bulbs. As the demand for energy-efficient lighting solutions continues to grow, leveraging aluminum’s lightweight properties in LED bulb manufacturing will undoubtedly play an important role in meeting these needs.

How does customization in Aluminum Die Casting contribute to LED bulb innovation?

With the rapid development of science and technology, LED light bulbs have become the mainstream of modern lighting. In this field, the customized application of aluminum die-casting technology is opening up a new world for LED bulb innovation. Aluminum die-casting not only provides excellent heat dissipation performance and lightweight design for LED bulbs, but its highly customized characteristics promote the diversity and flexibility of LED bulb design.

1. Design freedom brought by aluminum die-casting technology

Aluminum die-casting technology allows manufacturers to customize the shape, size and structure of LED light bulbs according to specific needs and application scenarios. Whether it’s a complex heat dissipation structure or a unique appearance, aluminum die casting can achieve high-precision manufacturing. This provides designers with greater creative space, making the design of LED light bulbs more colorful and meeting different market demands.

2. Optimize heat dissipation performance and improve LED efficiency.

The efficiency and lifespan of LED light bulbs are largely affected by their heat dissipation performance. Aluminum die-casting technology can produce LED bulb housings with excellent heat dissipation structures, ensuring that the heat generated by the LED chips during operation can be quickly and effectively dissipated. Through customized heat dissipation design, the thermal efficiency of LED bulbs can be further improved, extending their service life, while reducing energy consumption, and realizing a more energy-saving and environmentally friendly lighting solution.

3. Lightweight design, easy to install and apply

The lightweight properties of aluminum allow LED bulbs to achieve lightweight design while maintaining high performance. This not only facilitates the installation and replacement of light bulbs, but also makes LED lamps more advantageous in scenarios that require hanging or fixing, such as chandeliers and wall lamps. Customized aluminum die-casting technology can produce accurately adapted LED bulb structures according to different installation requirements, simplifying the installation process and improving ease of use.

4. Adapt to harsh environments and enhance durability

Aluminum has good corrosion resistance and strength. The LED bulb housing manufactured through aluminum die-casting technology can resist the erosion of harsh environments and ensure stable working performance in various climates and environments. Customized designs can be adjusted according to different regions and environmental conditions to create LED light bulb products that are more suitable for specific environments.

5. Conclusion

The customized application of aluminum die-casting technology has injected strong impetus into the innovation of LED light bulbs. It not only improves the quality and lifespan of LED bulbs in terms of physical performance, but also brings greater flexibility and diversity to them in terms of design. With the continuous advancement of technology and the diversification of market demand, the potential of aluminum die-casting customization will be further explored, helping the LED lighting industry move towards a better future.

What are the key advantages of using aluminum in LED bulb production?

The main advantages of using aluminum in LED bulb production include:

- Heat dissipation performance: Aluminum has excellent thermal conductivity and can conduct heat quickly. LED bulbs generate heat when they work. If the heat is not dissipated in time, it will affect the life of the LED. The aluminum casing helps reduce the operating temperature of the LED chip and prolongs the service life of the LED.

- Corrosion Resistance: Aluminum is highly resistant to moisture, oxidation and chemical attack. This makes the aluminum housing ideal for outdoor applications, capable of withstanding harsh weather conditions for extended periods of time.

- Environmentally Friendly: Aluminum is a renewable material that is easy to recycle and reuse. Therefore, the aluminum housing of LED street lights helps reduce resource waste and environmental impact, and is in line with the principles of sustainable development.

- Appearance and Durability: Aluminum housings can be given different surface treatments, such as anodized, spray-coated or electrocoated, for different looks and colors and increased durability.

- Cost-effectiveness: Aluminum is a relatively economical material, so the manufacturing cost of the aluminum housing of LED street lights is relatively low, which is conducive to controlling the overall cost.

- Lightweight: Aluminum is a lightweight material, which means LED bulbs made of aluminum are relatively lightweight, which makes them more convenient during installation and transportation.

To sum up, using aluminum as the main material of LED bulbs has multiple advantages, including heat dissipation performance, corrosion resistance, environmental protection, beauty and durability, high cost performance, portability, etc.

How does quality assurance in Aluminum Die Casting ensure reliable LED bulb performance?

In LED lighting equipment, the quality of aluminum die-casting plays a vital role in the reliability and performance of the bulb. The aluminum die-cast shell is not only the decoration of the light bulb, it also plays an important role in heat dissipation, mechanical strength, corrosion resistance and other aspects, thereby ensuring the performance and life of the LED light bulb.

1. Material quality

First, the material quality of the aluminum die-cast housing is key. Aluminum that is not pure enough or contains impurities may lead to a decrease in key properties such as thermal conductivity and mechanical strength. Therefore, choosing high-purity aluminum or aluminum alloy is the first step to ensure die-casting quality.

2. Mold design

The design of the mold has a decisive influence on the shape and accuracy of the aluminum die-cast housing. Any defects or errors in the mold may be directly transferred to the final product. Therefore, accurate mold design is the second step to ensure die casting quality.

3. Production process control

During the production process, from the injection of molten aluminum to cooling and demoulding, every step requires precise control. For example, the injection rate and temperature of molten aluminum, the cooling rate of the mold, etc. will all affect the quality of the product. Therefore, strict process control is the third step to ensure die-casting quality.

4. Product testing

Each batch of aluminum die-cast housings requires strict quality inspection, including appearance, size, mechanical properties, thermal conductivity, etc. Through these tests, you can ensure that the quality of your products meets expectations and standards. This is the fourth step to ensure die casting quality.

5. Environmental factors

In addition, the storage and working environment will also have an impact on the quality of the aluminum die-cast housing. For example, a humid environment may cause the aluminum casing to corrode and rust, affecting its thermal conductivity and appearance. Therefore, maintaining suitable storage environment and usage conditions is the fifth step to ensure die casting quality.

To sum up, the quality assurance of aluminum die-casting is a key link to ensure the reliable performance of LED bulbs. From material selection, mold design, production process control to product testing, every link requires strict control and management. Only in this way can we ensure the reliable performance of LED bulbs and provide users with high-quality products and services.

Can aluminum die-cast components be recycled in LED bulb manufacturing?

In the manufacturing process of LED light bulbs, aluminum die castings can be recycled.

Aluminum is a recyclable material, so aluminum die castings can be recycled, remelted and made into new aluminum products or aluminum die castings after they are scrapped. This method of recycling and reuse can not only reduce resource waste, but also reduce environmental impact and is in line with the principle of sustainable development.

In the LED light bulb manufacturing process, in order to realize the recycling of aluminum die castings, some measures need to be taken:

- There is a need to ensure that aluminum die castings are not damaged or contaminated during use so that their good material properties can be maintained when recycled.

- A complete recycling system needs to be established, including recycling sites, transportation and processing facilities, etc., to ensure that the recycling and processing process of aluminum die castings proceeds smoothly.

It should be noted that the recycling of aluminum die castings may be affected by some factors, such as the purity of the aluminum, impurity content, recycling process, etc. Therefore, during the recycling process, aluminum die castings need to be strictly inspected and processed to ensure that their quality and performance meet the requirements.

What sustainability initiatives are associated with Aluminum Die Casting for LED bulbs?

Sustainable Development Measures for Aluminum Die Castings for LED Bulbs

As the world pays increasing attention to sustainable development, the LED lighting industry is also actively seeking environmentally friendly and energy-saving solutions. Aluminum die-casting is an important material in the manufacturing of LED bulbs, and its sustainable development measures are of great significance in promoting the green development of the entire industry. This article will discuss sustainable development measures for aluminum die castings used in LED light bulbs.

1. Optimize design and improve material utilization

In the design stage of LED light bulbs, through optimized design, the use of aluminum die castings can be reduced and material utilization improved. For example, lightweight design is adopted to reduce unnecessary structural parts, thereby reducing the use of aluminum. At the same time, rationally plan the layout of parts to reduce waste in the mold manufacturing process, further reducing costs and resource consumption.

2. Use environmentally friendly materials

Choosing environmentally friendly aluminum materials and coatings is an important measure for the sustainable development of aluminum die castings for LED light bulbs. For example, recyclable aluminum alloy materials are used to reduce the burden on the environment. At the same time, low-volatile organic compound (VOC) coatings are used to reduce environmental pollution during the production process.

3. Promote circular economy

Circular economy is an important way to achieve sustainable development. In the manufacturing process of LED light bulbs, the recycling of aluminum die-casting parts should be promoted. By establishing a complete recycling system, we can recycle, classify, and reuse scrap aluminum die-casting parts to achieve effective utilization of resources and reduce dependence on natural resources.

4. Improve production efficiency

Improving production efficiency is an important means to reduce energy consumption and resource consumption. By introducing advanced production equipment and technology, optimizing the production process and improving production efficiency, energy consumption and raw material waste can be reduced and contribute to sustainable development.

5. Strengthen R&D and innovation

Innovation is an important driving force for sustainable development. In the field of aluminum die castings for LED bulbs, R&D innovation should be strengthened to develop more environmentally friendly and efficient manufacturing technologies and materials. Through technological breakthroughs, we can reduce energy and resource consumption in the manufacturing process and provide strong support for the sustainable development of the industry.

6. Strengthen policy guidance and supervision

The government should strengthen policy guidance and supervision of the LED lighting industry to promote the sustainable development of the industry. Formulate relevant policies and regulations to encourage companies to adopt environmentally friendly materials and manufacturing technologies, while increasing penalties for violations to ensure the green development of the industry.

In short, the sustainable development of aluminum die-casting parts for LED bulbs needs to start from multiple aspects such as design, materials, production, recycling, etc., through optimizing design, using environmentally friendly materials, promoting circular economy, improving production efficiency, strengthening R&D innovation, and strengthening policy guidance and regulatory measures to jointly promote the green development of the industry.

What emerging trends and innovations can be expected in Aluminum Die Casting for future LED bulbs?

In the future, aluminum die-casting technology for LED bulbs may have the following new trends and innovations:

- Lightweight design: As LED light bulbs increase in power and efficiency, aluminum die castings need to withstand higher thermal loads and mechanical stresses. Therefore,lightweight design will become an important trend in future aluminum die-casting technology. By optimizing materials and structures, the quality of aluminum die-casting parts can be reduced and their strength and durability improved.

- High-precision manufacturing: As the LED lighting market continues to expand and consumers have higher requirements for product quality, high-precision manufacturing will become an important development direction of aluminum die-casting technology. By introducing advanced manufacturing equipment and processes, the accuracy and consistency of aluminum die-casting parts can be improved to meet the needs of different application scenarios.

Intelligent manufacturing: With the rapid development of - Industry 4.0 and intelligent manufacturing, intelligent manufacturing will become an important innovation direction for aluminum die casting technology. By introducing advanced sensors, Internet of Things technology and big data analysis, we can achieve automated, flexible and intelligent manufacturing of aluminum die castings, improving production efficiency and product quality.

- Environmentally friendly materials: With the improvement of environmental awareness and the requirements of sustainable development, environmentally friendly materials will become an important innovation direction in aluminum die-casting technology. By introducing environmentally friendly materials such as recyclable aluminum alloy materials and low-VOC coatings, we can reduce the environmental impact of aluminum die castings and improve the environmental performance of products.

- Personalized customization: As consumers’ demand for personalization increases, personalization will become an important innovation direction in aluminum die-casting technology. By introducing advanced 3D printing technology and personalized customization platform, we can achieve rapid and personalized customization of aluminum die-casting parts to meet the personalized needs of consumers.

In short, in the future, the aluminum die-casting technology of LED bulbs will develop in the direction of lightweight, high precision, intelligence, environmental protection and personalization to meet market demand and promote the sustainable development of the industry.