PVC射出成形

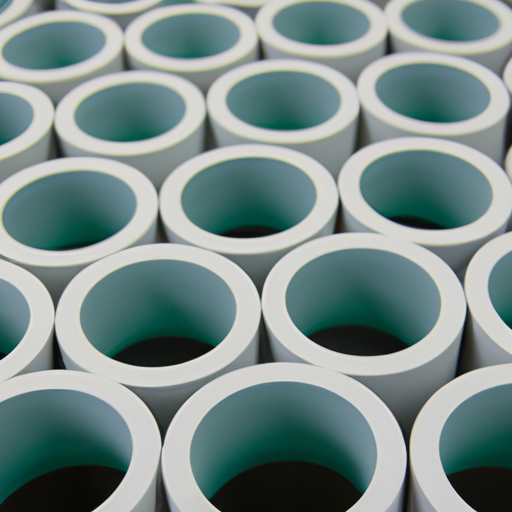

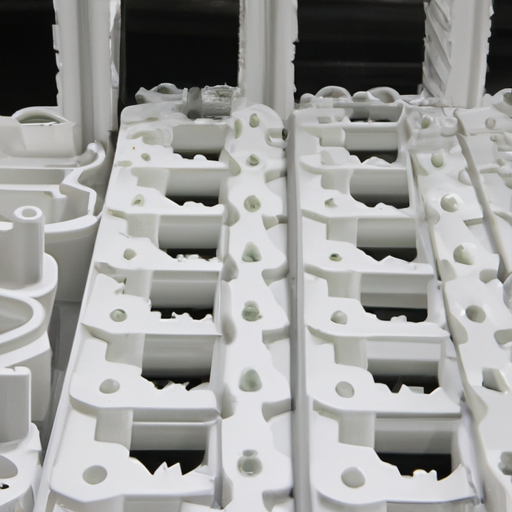

PVC Injection Molding We use in the production of various plastic products such as pipes, panels, window frames, flooring etc. Its process includes: material handling, mold design and manufacturing, injection molding machine operation, product cooling and molding, processing technology, etc. The advantages are high production efficiency, low production cost, and stable product quality.

PVC Injection Moulding Process

PVC injection molding process can make products in various shapes, such as pipes, cable bushings, workshop tools, etc. The manufactured products have excellent characteristics such as acid and alkali resistance, corrosion resistance and high temperature resistance.

PVC injection molding process is a manufacturing process that heats and melts polyvinyl chloride (PVC) resin and injects it into a mold to form the desired shape. Specific steps are as follows:

- PVC raw material preparation

- Heating and melting

- 射出成形

- cooling and solidification

- Take out the finished product

Get Started Now with Custom PVC Injection Moulding Services According to Your Needs!

Application of PVC Injection Moulding

PVC is also a commonly used injection molding material in injection molding services. It is mostly used in the production of window frames, door frames, pipes, drainage systems, wall panels and other construction industries. It is also used in the manufacture of insulation layers for wires and cables, automotive interior parts, dashboards, door panels, and window seals.