Aluminum alloy die-casting is a manufacturing technology with a very wide range of applications. In order to ensure the final molding effect of die-casting parts, an excellent aluminum alloy die-casting mold is indispensable.

Mold material selection

The material used to design the mold will directly affect the difficulty of the entire mold design and the service life of the mold. At Mindwell, professional mold designers will select mold materials according to actual needs. Analyze the target product, then comprehensively consider various manufacturing costs, process parameters, equipment requirements and other factors, and select a more suitable mold material, which can effectively extend the service life of the mold and reduce manufacturing costs.

The material selection of aluminum alloy die-casting molds generally requires consideration of multiple factors, such as cost, wear resistance, high temperature performance and toughness. Common aluminum die casting mold materials include:

- H13 steel: H13 steel is the most commonly used type of mold steel. It has good wear resistance and high temperature performance and is suitable for the production of large quantities of aluminum alloy parts.

- 8407 steel: 8407 steel has higher wear resistance and thermal fatigue resistance and can replace H13 steel to a certain extent.

- The third generation of aluminum alloy mold steel: The third generation of aluminum alloy mold steel is very popular due to its excellent performance and relatively low manufacturing cost, and is widely used in mass production.

At the same time, the difficulty of repair and maintenance of the mold, as well as the service life and cost of the mold also need to be considered.

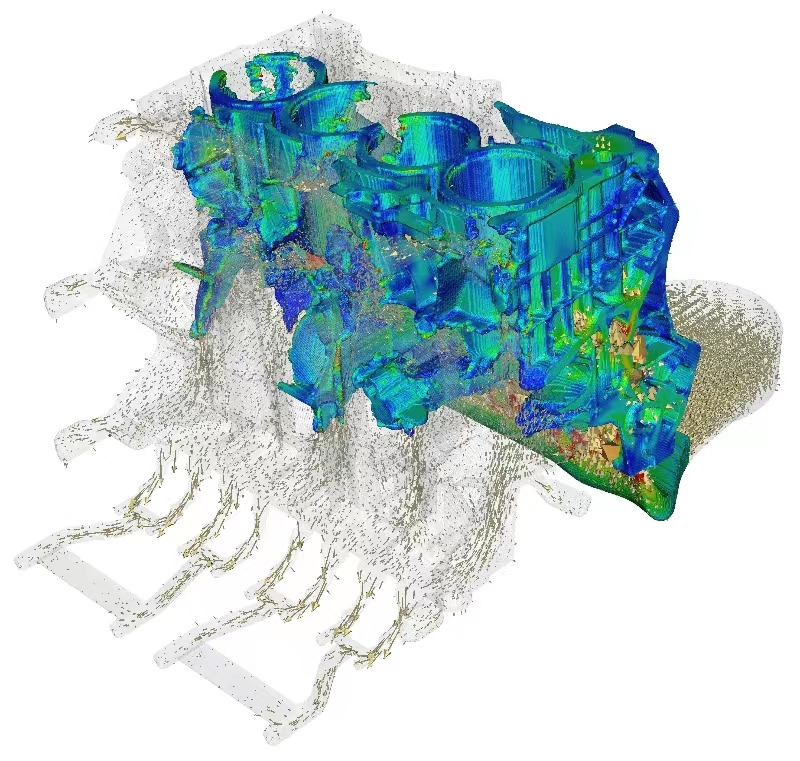

Shape design of the mold

The shape design of the mold is also one of the important factors affecting the quality of aluminum alloy die-casting. Mindwell will formulate the optimal matrijsontwerp plan according to the needs of the customer, analyze and evaluate the size and shape of the entire product, and then select the most suitable mold shape. and size. To ensure that the aluminum alloy solution can be filled evenly in the mold, thereby obtaining ideal molding effect and product quality.

Aluminum alloy die-casting molds include the following main categories:

- Fixed mold: The fixed mold is the most basic aluminum alloy die-casting mold. It consists of a template, a mold box, a mold core, etc., and is used to manufacture aluminum alloy parts with simple structures.

- Detachable mold: Detachable mold has the advantages of easy installation, disassembly and cleaning, and can produce more complex aluminum alloy parts.

- Sliding plug mold: The sliding plug mold adopts a sliding mechanism, which can effectively control the flow and dimensional accuracy of aluminum alloy, and is used to manufacture more complex aluminum alloy parts.

- Composite mold: Composite mold usually consists of two or more molds with different structures, and can produce aluminiumlegering parts with complex shapes and internal structures.

- Automated molds: Automated molds use automated control technology to fully automate the aluminum alloy die-casting process, improving production efficiency and quality stability.

- Cooling system design

The mold needs to be preheated before production. However, due to the technological characteristics of aluminum alloy die-casting, it is easy to age during the production process, which makes the cooling system in the mold design very important. When designing molds, Mindwell generally uses an internal cooling system. This method can adjust the temperature inside the mold through specific pipelines, speed up product molding, improve production efficiency, and effectively reduce mold aging and damage caused by excessive temperature.

Aluminum alloy die casting mold design is the most critical part of the entire die casting manufacturing process. Mindwell has professional designers and complete processing facilities. Through scientific mold design combined with many years of experience in the industry, it can provide users with perfect aluminum alloy die-casting molds so that it can produce higher-quality products more efficiently.