Spuitgieten

We bieden hoogwaardige aangepaste spuitgietservices voor zowel kleine als grote spuitgietonderdelen, met bijbehorende spuitgietapparatuur voor aluminium- en zinklegeringen, waar we uitgebreide ervaring mee hebben. Voor andere materiaalvereisten kunnen we via e-mail communiceren voor maatwerk. Onze gegoten onderdelen worden veel gebruikt in verschillende toepassingen, zoals auto's, motorfietsen, koellichamen en industriële apparatuur.

Ons bedrijf heeft een professioneel team van technische ingenieurs die met u zullen communiceren op een één-op-één manier tijdens het hele proces van het project, van productontwerp, ontwerp van schimmels, monsterproductie en massaproductie, tot verpakking en transport tijdens het hele projectproces, zullen we diepgaand met u communiceren en u aan uw professioneel advies en snelle offerte geven.

Productcategorieën

- CNC-bewerking (4)

- Spuitgieten (53)

- Spuitgieten (5)

- Vormen (1)

De geschiedenis van spuitgieten

De wortels van het spuitgieten gaan terug tot het begin van de 19e eeuw, met aanzienlijke vooruitgang in het midden van de 20e eeuw waardoor het een wijdverspreide industriële praktijk werd. Innovaties in matrijsontwerp en metallurgie speelden een sleutelrol in de ontwikkeling.

Spuitgieten is een metaalgietproces waarvan de oorsprong teruggaat tot het begin van de 19e eeuw. In die tijd werd deze technologie gebruikt om kleine gietstukken en onderdelen te produceren, voornamelijk in sectoren zoals de machine- en autofabricage. Het was echter pas in het midden van de 20e eeuw dat het spuitgieten geleidelijk een algemeen aanvaarde industriële praktijk werd, omdat de technologie zich bleef ontwikkelen en innoveren.

Bij de ontwikkeling van de spuitgiettechnologie hebben innovaties in matrijsontwerp en metallurgie een sleutelrol gespeeld. De matrijs is een belangrijk onderdeel van het spuitgietproces en het ontwerp en de productiekwaliteit hebben een directe invloed op de kwaliteit en productie-efficiëntie van het gietstuk. In het midden van de 20e eeuw, met de voortdurende vooruitgang van matrijsontwerp en productietechnologie, zijn de nauwkeurigheid en levensduur van spuitgietmatrijzen aanzienlijk verbeterd, waardoor de efficiëntie en kwaliteit van spuitgietproductie verder zijn verbeterd.

Tegelijkertijd biedt de vooruitgang van de metallurgische technologie ook sterke ondersteuning voor de ontwikkeling van de spuitgiettechnologie. In het spuitgietproces zijn de vloeibaarheid en het vullend vermogen van het metaal sleutelfactoren die de kwaliteit en productie-efficiëntie van het gietstuk beïnvloeden. Door het metallurgische proces te verbeteren, kunnen de samenstelling en structuur van het metaal worden geoptimaliseerd en kunnen de vloeibaarheid en het vullend vermogen van het metaal worden verbeterd, waardoor de efficiëntie en kwaliteit van de spuitgietproductie verder verbeteren.

Bovendien heeft de moderne spuitgiettechnologie met de voortdurende ontwikkeling van computertechnologie en automatiseringstechnologie een hoog niveau van automatisering en intelligentie bereikt. Door middel van computersimulatie en een geoptimaliseerd ontwerp kunnen verschillende parameters in het spuitgietproces nauwkeurig worden geregeld om een nauwkeurige productie van gietstukken te bereiken. Tegelijkertijd heeft de toepassing van geautomatiseerde productielijnen de productie-efficiëntie en -kwaliteit sterk verbeterd.

De ontwikkeling van de spuitgiettechnologie kan niet los worden gezien van innovaties in matrijsontwerp en metallurgie, evenals de voortdurende ontwikkeling van computertechnologie en automatiseringstechnologie. De vooruitgang van deze technologieën heeft de efficiëntie en kwaliteit van de spuitgietproductie sterk ondersteund en de wijdverspreide toepassing en ontwikkeling van spuitgiettechnologie bevorderd.

Inhoudsopgave

Soorten spuitgieten

Volgens de verschillende krachtbronnen bij het spuitgieten, is spuitgieten onderverdeeld in verschillende types; elk type heeft zijn eigen specifieke toepassingen en behoeften. De volgende drie zijn de belangrijkste types spuitgieten:

Spuitgieten onder hoge druk:

- Principe: vloeibaar metaal onder druk in een mal injecteren. Deze druk zorgt ervoor dat het metaal de mal snel en gelijkmatig vult, waardoor gietstukken van hoge kwaliteit en met precieze afmetingen worden geproduceerd.

- Toepassing: Drukgietwerk wordt voornamelijk gebruikt om onderdelen te produceren die een hoge sterkte en precisie vereisen, zoals motoronderdelen, tandwielen, lagers, enz.

- Voordelen: Door injectie onder hoge druk vult het metaal de matrijs snel en gelijkmatig, waardoor er minder holtes en krimpholtes ontstaan.

Spuitgieten met zwaartekracht:

- Principe: Vloeibaar metaal stroomt onder zwaartekracht in de mal. Mallen worden meestal ontworpen met een poort waardoor vloeibaar metaal in de mal stroomt.

- Toepassing: Het afgietsel van de zwaartekrachtmatrijs wordt hoofdzakelijk gebruikt om eenvoudige delen te produceren die geen hoge precisie vereisen, zoals autodelen en meubeldelen.

- Voordelen: De apparatuur is eenvoudig, goedkoop en geschikt voor massaproductie.

Spuitgieten onder lage druk:

- Principe: Vloeibaar metaal wordt onder lagere druk in de mal gespoten. Deze druk ligt ergens tussen die van het zwaartekrachtgieten en hogedrukgieten in.

- Toepassing: Spuitgieten onder lage druk is geschikt voor de productie van onderdelen met een gemiddelde complexiteit en precisie, zoals onderdelen van huistoestellen, bouwonderdelen, enz.

- Voordelen: Het combineert de hoge kwaliteit van spuitgieten onder druk met de lage kosten van spuitgieten onder zwaartekracht, terwijl schade aan de gietvorm door hoge druk vermeden wordt.

Materialen die worden gebruikt bij spuitgieten

De materialen die worden gebruikt in het spuitgietproces hangen voornamelijk af van de specifieke vereisten van het gietstuk en het toepassingsscenario. Bij de keuze van de gietmaterialen moet rekening worden gehouden met factoren zoals het toepassingsscenario, de grootte, de vorm, het gewicht en de kosten van het gietstuk. De juiste materiaalkeuze en verwerkingstechnologie hebben een directe invloed op de kwaliteit, prestaties en levensduur van het gietstuk. Hieronder volgen enkele veelgebruikte gietmaterialen en hun eigenschappen:

Aluminium:

- Fysische eigenschappen: Aluminium is een licht, glanzend metaal met een goed elektrisch en thermisch geleidingsvermogen. De dichtheid is lager, ongeveer 2,7 g/cm3.

- Mechanische eigenschappen: Aluminium heeft een relatief lage sterkte en hardheid, maar een goede vervormbaarheid en plasticiteit. Hierdoor kan het aluminium gemakkelijk vloeien en de mal vullen tijdens het spuitgietproces.

- Corrosiebestendigheid: Aluminium is gevoelig voor oxidatie in bepaalde omgevingen, waarbij een dichte beschermende laag aluminiumoxide wordt gevormd, wat de corrosiebestendigheid ten goede komt.

- Toepassingen: Aluminium is een van de meest gebruikte materialen in de spuitgietindustrie en wordt veel gebruikt in de auto-industrie, elektronica, bouw en consumptiegoederen.

Zink:

- Fysische eigenschappen: Zink is een grijs, glanzend metaal met een hoge dichtheid (ongeveer 7,14 gram per kubieke centimeter).

- Mechanische eigenschappen: Zink heeft een relatief lage sterkte en hardheid, maar een goede vervormbaarheid en plasticiteit. Tijdens het spuitgietproces vloeit zink snel en vult het de mal.

- Corrosiebestendigheid: Zink oxideert gemakkelijk in vochtige omgevingen en vormt een beschermende zinkoxidelaag die de corrosiebestendigheid helpt verbeteren.

Toepassing: Zink wordt voornamelijk gebruikt bij de productie van kleine spuitgietonderdelen, zoals sloten, speelgoed, meubeldelen, enz.

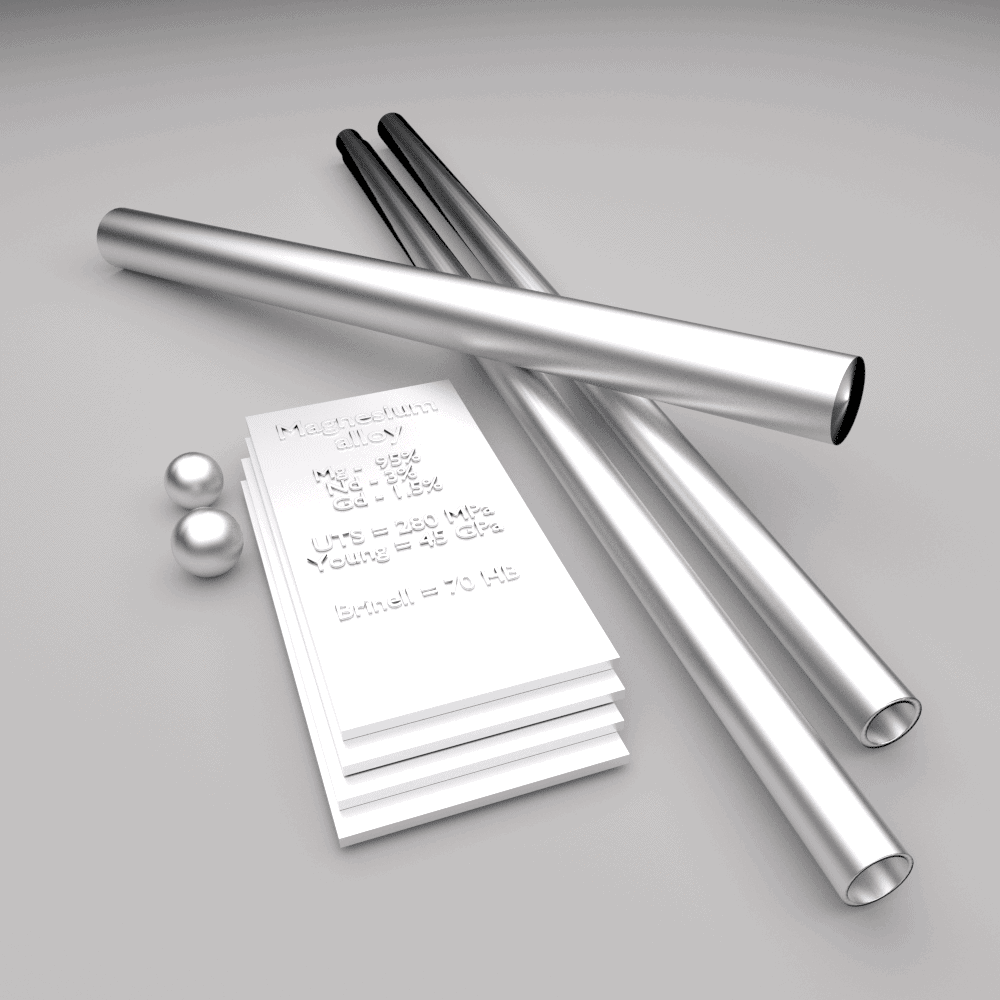

Magnesium:

- Fysische eigenschappen: Magnesium is een licht, glanzend metaal met een lage dichtheid (ongeveer 1,74 gram/kubieke centimeter).

- Mechanische eigenschappen: Magnesium heeft een hoge sterkte en stijfheid, maar ook een goede vervormbaarheid en plasticiteit. Tijdens het spuitgietproces vloeit magnesium snel en vult het de mal.

- Corrosiebestendigheid: Magnesium heeft een relatief lage corrosiebestendigheid en vereist een oppervlaktebehandeling of coating om de corrosiebestendigheid te verhogen.

Toepassing: Magnesium wordt voornamelijk gebruikt bij de vervaardiging van elektronische producten, auto-onderdelen, enz. Magnesium wordt ook veel gebruikt in de lucht- en ruimtevaart vanwege zijn lichte gewicht en hoge sterkte.

Alle drie de materialen vereisen de juiste behandeling en nabewerking tijdens het spuitgietproces om de kwaliteit en prestaties van het gietstuk te garanderen. Bovendien kunnen specifieke toepassingsscenario's en vereisten de selectie van andere soorten materialen of speciale behandelingen vereisen.

Naast de bovengenoemde metalen worden ook bepaalde niet-metalen materialen zoals kunststoffen en keramiek vaak gebruikt om specifieke soorten spuitgietwerk te maken. Kunststoffen worden bijvoorbeeld vaak gebruikt om onderdelen te maken met eenvoudige structuren en lage sterktevereisten, terwijl keramiek wordt gebruikt om onderdelen te maken met een hoge hardheid en slijtvastheid.

Beschrijving spuitgietproces

The die-casting process is an efficient and precise manufacturing method suitable for producing a variety of metal parts with complex shapes and high precision requirements. By optimizing process parameters and controlling every aspect of the production process, the quality and production efficiency of die-cast products can be further improved. The following is a detailed description of the die-casting process from Mindwell:

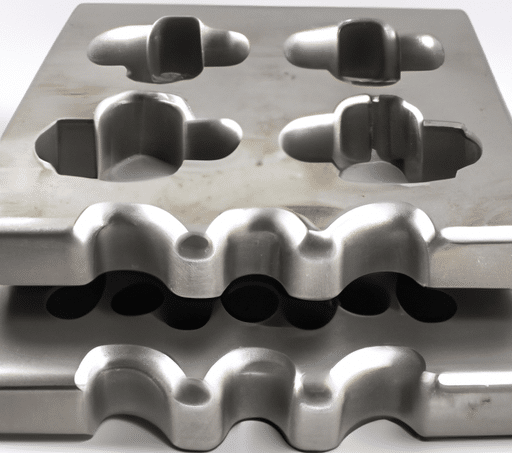

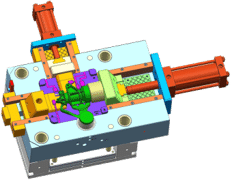

1.Mold design and manufacturing:

The first step in the die casting process is to design and build the mold. The design of the mold needs to consider factors such as the product’s shape, size, material, and production requirements.

Molds are usually made of high-strength steel and can withstand high pressure and temperature. The internal structure of the mold is complex to ensure that the molten metal can be evenly distributed and fill the entire mold when injected.

2.Molten metal preparation:

Select appropriate metal materials such as aluminum, zinc, magnesium, etc. according to product requirements. These metals are heated to a molten state for injection into molds.

During the preparation of molten metal, the metal’s temperature and composition need to be controlled to ensure the quality of the final product.

3.Injection process:

Molten metal is injected into the mold at high pressure. Injection pressure usually ranges from tens to hundreds of MPa, depending on the product requirements and the properties of the metal.

Parameters such as injection speed, pressure, and temperature need to be controlled during the injection process to ensure that the metal can fill the mold evenly and completely.

4.Cooling and solidification:

After the metal fills the mold, it needs to be cooled quickly to allow the metal to solidify and form into the desired shape. Cooling methods can be natural cooling or forced cooling, depending on production requirements.

During the cooling process, the cooling speed and time need to be controlled to avoid internal stress and distortion.

5.Ejection and pickup:

When the metal is completely solidified, the molded part can be ejected from the mold by an ejection mechanism. The design of the ejection mechanism needs to take into account the shape and size of the product to ensure that the parts can be demoulded smoothly.

After taking out the parts, they need to be inspected and cleaned to remove burrs and other undesirable defects.

6.Post-processing and inspection:

Perform post-processing on parts as needed, such as heat treatment, surface treatment, machining, etc. These treatments improve the performance and appearance quality of the part.

Strict inspection and testing of finished products is carried out to ensure that they meet design requirements and quality standards. This includes testing of dimensional accuracy, surface quality, mechanical properties and more.

Advantages of die casting

The die-casting process offers a variety of advantages that make it the preferred manufacturing method in many industries. These advantages give the die-casting process significant advantages in improving product quality, reducing costs, and increasing production efficiency. Here are the main advantages of the die-casting process:

- High precision: The die-casting process is capable of producing parts with high precision and dimensional stability. The dimensional accuracy of die-cast parts is very high due to the precision of mold design and manufacturing, as well as pressure and temperature control when injecting metal.

- High production efficiency: The die-casting production process has a high degree of automation and high production efficiency. The dimensional accuracy of die-cast parts is very high due to the precision of mold design and manufacturing, as well as pressure and temperature control when injecting metal.

- Cost Savings: Because die-cast parts are formed in one go, there is no need for subsequent machining or adjustments. This significantly saves post-processing costs and time and improves production efficiency.

- Full utilization of materials: In the die casting process, metal materials can be fully utilized. Because the metal is injected into the mold under high pressure, it is evenly distributed throughout the mold, leaving no unused portions.

- Strong applicability: The die-casting process can be used to produce a variety of parts with complex shapes, small sizes, and light weight. This makes it the preferred manufacturing method in many industries such as automotive, electronics, consumer goods, and more.

- Highly customizable: The design and manufacturing of die-casting molds are relatively flexible and can be customized according to customer needs. This allows the die casting process to meet a variety of specific needs and design requirements.

- Environmentally Friendly: The die-casting process generates less waste and off-gassing than other manufacturing methods. In addition, with the advancement of technology, many die-casting equipment have adopted environmentally friendly designs to further reduce the impact on the environment.

- Easy to automate: The die-casting process is easy to realize automated production. By using advanced robotics and automation equipment, efficient and continuous production can be achieved, manual intervention reduced, and production efficiency and quality improved.

- Quick mold change: In die-casting production, mold replacement is relatively fast and simple. This makes it more cost-effective to produce multiple different parts or in small batches.

- Good mechanical properties: Die-cast parts usually have excellent mechanical properties, such as strength, hardness, wear resistance, corrosion resistance, etc. This enables them to maintain stable performance in a variety of harsh environments.

Application of die casting

The die-casting process is widely used in various fields. It can meet a variety of different needs and produce high-quality, high-precision parts. Here are the main applications of die casting in various fields:

Auto-industrie:

Die casting plays a major role in the automotive industry. Key components such as engines, transmissions, and wheels are manufactured through the die-casting process.

Die-cast parts have the characteristics of high precision, high strength and lightweight, and can meet the performance and safety requirements of cars.

Electronic field:

The electronic field requires high precision and reliability of components, and the die-casting process can meet these requirements.

Die-cast parts are used to make housings, connectors, koellichamen, etc. for electronic equipment. These parts often need to have good electrical conductivity and corrosion resistance.

Consumer goods sector:

The field of consumer goods has high requirements on the appearance and durability of products, and the die-casting process can meet these requirements.

Die-cast parts are used to manufacture a variety of consumer products such as furniture, lighting fixtures, tableware, and more. These parts often need to have an aesthetic appearance and good corrosion resistance.

Aerospace sector:

The aerospace industry has very high requirements on precision and reliability of parts, and the die-casting process can meet these requirements.

Die-cast parts are used to manufacture parts for aircraft, rockets and other aircraft, such as engine components, structural parts, etc. These parts typically require excellent strength and corrosion resistance.

Medical area:

The medical field also requires high precision and reliability of components, and the die-casting process can meet these requirements.

Die-cast parts are used to make medical devices, such as surgical instruments, medical device accessories, etc. These parts typically need to have excellent strength and corrosion resistance while meeting medical-grade requirements.

Furnishing industry:

In the furniture industry, the die-casting process is commonly used to manufacture parts for furniture such as chairs and tables.

Die-cast parts feature high precision, high strength and are lightweight, ensuring the stability and safety of furniture.

For example, the seat’s support parts, connectors, etc. are manufactured through a die-casting process to ensure the durability and safety of the seat.

Security surveillance field:

In the field of security monitoring, die-casting technology is often used to manufacture parts for cameras, monitors and other equipment.

These parts often need to have good strength and corrosion resistance to ensure the stability and durability of the equipment.

For example, the camera’s bracket, base, etc. are manufactured through the die-casting process to ensure the stability and safety of the equipment.

Die casting quality control

Maintaining strict quality control measures is essential for die casting. Inspection and testing procedures ensure the final product’s reliability and functionality. The following is a detailed introduction to Mindwell’s die casting quality control measures:

Mold quality control:

- Mold is the core of the die-casting process, and its quality directly affects the quality and performance of the final product.

- The design and manufacture of molds need to follow strict standards and specifications to ensure the precision, strength and durability of the molds.

- During the production process, molds need to be inspected and maintained regularly to ensure they are in good working order.

Raw material control:

The quality of raw materials has an important influence on the quality of die-casting products.

- The metal materials purchased by Mindwell should comply with relevant standards and specifications and undergo strict inspection and testing to ensure that their composition and physical properties meet the requirements.

- Contamination or damage to raw materials should be avoided during storage and transportation.

Manufacturing process control:

- The die-casting production process needs to be strictly controlled to ensure the stability and consistency of each process.

- Parameters during the production process, such as injection pressure, injection speed, mold temperature, etc., should be precisely controlled to ensure the uniformity and completeness of metal filling.

- During the production process, equipment should be inspected and maintained regularly to ensure the stability and reliability of the equipment.

Product Inspection and Testing:

- Die-cast products require rigorous inspection and testing during and after production.

- A comprehensive evaluation of the product is carried out through appearance inspection, dimensional measurement, mechanical property testing and other means.

- For unqualified products, they should be reworked or scrapped in time to avoid entering the market.

Quality management system:

- Mindwell Company has established a perfect quality management system.

- Mindwell ensures that each department and employee is clear about their responsibilities and requirements by formulating clear quality standards and operating procedures.

- Our quality management system is regularly reviewed and improved to adapt to changing market needs and technological developments.

Employee training and awareness improvement:

- Employees are important factors in the die casting production process, and their skills and awareness have a direct impact on product quality.

- Mindwell provides regular training and skills improvement to its employees so that they can understand and master the key technologies and quality control requirements of the die-casting process.

- Improve the quality awareness of employees so that they can consciously comply with quality standards and operating procedures.

Continuous improvement and innovation:

- Die-casting quality control is a continuous improvement process. Mindwell engineers collect and analyze data during the production process to identify problems and take appropriate measures for improvement.

- Mindwell encourages employees to put forward opinions and suggestions for improvement, stimulate their innovative spirit, and promote the continuous progress of die-casting technology.

In short, die-casting quality control is a systematic work, involving molds, raw materials, production processes, product inspection and other links. By implementing strict quality control measures, the reliability and functionality of the final product can be ensured, Mindwell’s competitiveness can be improved, and high-quality die-cast parts can be brought to customers.

The impact of die casting on the environment

The die-casting process has a certain impact on the environment, but by adopting environmentally friendly practices and recycling measures, the development of sustainable manufacturing processes can be promoted and the environmental impact reduced. Mindwell actively takes measures to strengthen environmental management, improve environmental awareness, and ensure that the die-casting production process meets environmental requirements. The following is a detailed introduction to the environmental impact of die casting:

Exhaust gas emissions:

During the die-casting process, metal heating and melting will produce a large amount of exhaust gas. These exhaust gases may contain harmful substances, such as heavy metals and other chemicals, which if directly discharged into the atmosphere, can cause negative effects on the environment and human health.

- In order to reduce exhaust emissions, the following measures can be taken:

Use environmentally friendly melting agents and release agents to reduce the generation of harmful substances. - Equipped with exhaust gas treatment equipment to filter and purify the exhaust gas to ensure that the exhaust gas emissions meet environmental protection standards.

- Adopt closed smelting and pouring systems to reduce waste gas emissions.

Wastewater treatment:

During the die casting process, metal cleaning, cooling and grinding generate a large amount of wastewater. These wastewaters may contain heavy metals and other harmful substances, which if directly discharged into the environment without treatment, can cause harm to aquatic life and human health.

In order to reduce the environmental impact of wastewater, the following measures can be taken:

- Equip wastewater treatment equipment to perform filtration, neutralization, precipitation and other treatments on wastewater to ensure that wastewater meets discharge standards.

- Adopt a water recycling system to reduce the use of fresh water and reduce wastewater emissions.

Waste water is recycled and reused, such as for cooling during pouring processes.

Waste disposal:

During the die-casting process, some waste materials will be generated, such as metal scraps, defective products, etc. If these wastes are not properly disposed of, they can cause environmental pollution.

To reduce the impact of waste on the environment, you can take the following steps:

- Collect and process waste materials into categories, such as metal scraps that can be recycled and reused and defective products that can be sold as scrap or otherwise processed.

- Use environmentally friendly and recyclable materials to manufacture molds and auxiliary equipment to reduce the consumption of resources.

Centralize the processing, recycling and reuse of recyclable waste materials, such as sending them to professional recycling companies for recycling and reuse.

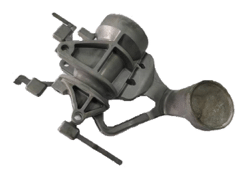

Die casting case

A manufacturer in a certain country needs to produce a complex aluminum alloy die casting for use in parts of their equipment. In order to meet production needs, we decided to use the die-casting process after in-depth communication and discussions with our customers.

Mold design:

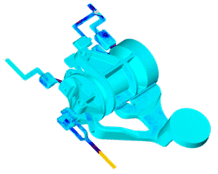

First, Mindwell’s mold designers designed the structure and size of the mold based on product drawings and technical requirements. We used professional CAD software for modeling and simulated the flow path and filling process of the metal liquid to ensure that the mold could meet production requirements.

Mold making:

In the mold manufacturing process, we use high-strength steel as the mold material to ensure the stability and durability of the mold. During the manufacturing process, the design drawings are strictly followed to ensure that the mold’s accuracy and size meet the requirements. At the same time, the mold was heat treated and surface treated to improve the mold’s hardness and wear resistance.

Die casting production:

After the mold manufacturing is completed, die-casting production begins. During the die casting process, the metal liquid flows into the mold through the flow channel, and then solidifies under high pressure into the casting. During the production process, injection pressure, injection speed, mold temperature and other parameters are controlled to ensure that the metal liquid can fill the mold evenly and fully. At the same time, post-processing is performed on the castings, such as cleaning, grinding, polishing, etc., to improve the finish and precision of the castings.

Die casting FAQ

What is die casting and how does it work?

Die casting is a widely used manufacturing process that involves the production of metal parts through the injection of molten metal into a mold cavity, known as a die. This process is highly efficient and allows for the production of complex and precise parts with excellent dimensional accuracy.

The die casting process typically involves the following steps:

- Clamping: The two halves of the die, known as the cover die and ejector die, are securely clamped together.

- Injection: Molten metal, usually an alloy of aluminum, zinc, or magnesium, is injected under high pressure into the die cavity through a gate.

- Cooling: The molten metal quickly solidifies and takes the shape of the die cavity. Cooling channels within the die help expedite the solidification process.

- Ejection: Once the metal has solidified, the two halves of the die are separated, and the newly formed part is ejected.

Trimming and - Finishing: The part may undergo additional processes such as trimming, deburring, and surface finishing to achieve the desired final product.

There are two main types of die casting:

- Hot Chamber Die Casting: In this process, the injection system is immersed in the molten metal, eliminating the need for a separate furnace. This method is commonly used for alloys with low melting points, such as zinc.

- Cold Chamber Die Casting: In this process, the molten metal is ladled into a separate injection chamber before being injected into the die cavity. This method is suitable for alloys with high melting points, such as aluminum and magnesium.

Conclusie

Die casting is a versatile and efficient manufacturing process that enables the production of high-quality metal parts with exceptional precision. With its numerous advantages and wide-ranging applications, die casting continues to be a preferred choice for manufacturers across various industries.

What are the common challenges in die casting?

There are indeed some common challenges with the die casting process, and below I’ll go over them in more detail and how to deal with them.

1. pores

Porosity is one of the common defects in the die casting process. It is usually caused by insufficient fluidity or insufficient filling of the metal liquid. Porosity can lead to reduced strength and corrosion resistance in the casting, and in some cases, the pores can even serve as the starting point for cracks.

To reduce porosity, you can take the following steps:

Optimize the mold design to ensure smooth flow channels and reduce the flow resistance of metal liquid.

Control the temperature and fluidity of the metal liquid to ensure that the metal liquid can fully flow and fill the mold.

Adjust the injection pressure and speed so that the metal liquid can fill the mold cavity more fully.

2. Shrink

Shrinkage is another common challenge during the die casting process. Metal liquid will shrink during the cooling and solidification process. If the shrinkage is not controlled properly, it may cause dimensional deviation, deformation and other problems of castings.

To control shrinkage, the following measures can be taken:

Optimize the mold design to make the heat conduction between the mold and the casting more uniform and reduce the difference in shrinkage of each part of the casting.

Control the cooling rate and temperature gradient of the metal liquid to reduce the shrinkage of the casting.

Dimensional measurements and adjustments are made during the production process to ensure that the casting dimensions meet the requirements.

3. Quality control

In order to cope with these challenges, it is very important to establish a strict quality control system. This includes:

Develop detailed quality standards and operating procedures to ensure that every employee is aware of their responsibilities and requirements.

Regularly inspect and maintain equipment and processes to ensure their stability and reliability.

Collect and analyze data during the production process to identify problems and take corresponding measures for improvement.

In short, there are indeed some challenges in the die-casting process, but by optimizing the mold design, controlling the flow and cooling of the metal liquid, and establishing a strict quality control system, these challenges can be effectively dealt with and the quality and production efficiency of the die-casting products can be improved.

How does die casting compare to other manufacturing processes like forging and machining?

Die casting is a manufacturing process in which molten metal is injected into a mold and then cooled and solidified to obtain metal products of the desired shape and size. Compared to other manufacturing processes, die casting offers the following advantages:

- High precision: The precision of the die-casting mold is very high, reaching the micron level, so the dimensional accuracy of the die-cast products is also very high.

- High efficiency: During the die casting process, the molten metal is quickly cooled and solidified under high pressure, so the production efficiency is very high.

- Good surface quality: Because the molten metal is cooled and solidified in the mold during the die-casting process, the surface of the product is smooth and does not require too much post-processing.

- Complex shapes can be manufactured: Due to the very high precision of die-casting molds, products of very complex shapes and sizes can be manufactured.

- Low cost: Compared with traditional processes such as forging and machining, die casting is less expensive.

In short, die casting is a very efficient, precise and economical manufacturing process suitable for manufacturing various metal products, such as automotive parts, electronic products, etc.

Is die casting environmentally friendly?

Die casting is a widely used manufacturing process that involves injecting molten metal under high pressure into a mold cavity. It is known for its ability to produce complex shapes with high accuracy and excellent surface finish. However, when assessing the environmental impact of die casting, there are several factors to consider.

energy efficiency

One of the key factors that determine the environmental friendliness of any manufacturing process is its energy efficiency. Die casting is known for its high energy efficiency compared to other metal forming technologies. This process requires less energy to produce finished parts as it involves minimal material waste and shorter production cycles. The use of advanced technologies such as electric machines can further increase energy efficiency by reducing power consumption.

Materials used

Die-casting uses nonferrous metals such as aluminum, zinc and magnesium, which are highly recyclable. These metals can be melted and reused multiple times without losing their properties. The ability to recycle and reuse materials significantly reduces the need for primary metal extraction, thereby protecting natural resources and minimizing environmental impact.

reduce waste

Die casting is a near-net-shape manufacturing process, meaning it requires minimal post-processing. This reduces the generation of scrap compared to other metal forming techniques such as machining. Any scrap produced during the die casting process can be collected and recycled, further reducing waste sent to landfill.

Emissions and air quality

Although die casting is generally considered environmentally friendly, the process does produce emissions that need to be managed properly. Melting metal can release volatile organic compounds (VOCs) and other air pollutants. However, with the implementation of advanced pollution control technology such as exhaust systems and filters, emissions can be effectively controlled and minimized.

water consumption

Die casting requires water for cooling, but the amount is relatively low compared to other manufacturing processes. In addition, the water used in the die-casting process can be recovered and reused, reducing overall water consumption.

overall environmental impact

Taking into account energy efficiency, material recyclability, waste reduction, and controlled emissions, die casting can be considered an environmentally friendly manufacturing process. Its ability to produce complex parts with minimal material waste and its potential for recycling make it a sustainable option for various industries.

continuous improvement

Despite the positive impact of die casting on the environment, the industry continues to strive to further reduce its impact on the environment. Mindwell continues to develop more sustainable alloys, improve energy efficiency and implement advanced pollution controls. These efforts make die casting even more environmentally friendly in the future.

In summary, die casting offers a variety of environmental benefits due to its energy efficiency, material recyclability, waste reduction and controlled emissions. At Minidwell, we prioritize sustainable practices and continue to improve processes to further reduce our impact on the environment.

What recent innovations have impacted the die casting industry?

The latest innovations in die casting include advanced technologies, automation and sustainable practices. These innovations increase efficiency and reduce costs. These innovations play an important role in the field of die casting, improving production efficiency and reducing costs, while also contributing to environmental protection.

1.Advanced technology:

- 3D printing molds: Using 3D printing technology to manufacture molds can achieve more complex shapes and finer details. This technology reduces the time and cost of mold manufacturing and improves the accuracy and durability of the mold.

- Additive manufacturing: Additive manufacturing technology can create complex metal structures by adding materials layer by layer. This technology can be used to make complex die-casting molds, improving the accuracy and durability of the molds.

2. Automation:

- Robots and automation equipment: During the die-casting process, robots and automation equipment can be used to automate pouring, picking, polishing and other processes. This automation can improve production efficiency, reduce manual operations, and reduce costs and error rates.

- Intelligent control system: By introducing an intelligent control system, the die-casting process can be monitored and adjusted in real time, thereby improving product quality and production efficiency.

3. Sustainable practices:

- Scrap recycling: As mentioned earlier, scrap recycling is an important innovation in the field of die casting. By recycling waste materials and reusing them, you can reduce the generation of waste materials, reduce costs, and also help environmental protection.

- Energy optimization: By optimizing the heating system, cooling system, etc., you can reduce energy consumption and reduce the impact on the environment.

- Environmentally friendly materials: The use of environmentally friendly materials can reduce pollution to the environment and also help protect human health.

Why Choose Mindwell as a Die Casting Service Manufacturer?

When choosing a die casting service provider, it is crucial to choose a company that can meet your specific requirements and provide high-quality products. Mindwell has established itself as a reliable and trustworthy supplier in the industry. Our company has the following advantages:

1. Experience and expertise

Mindwell has been in the die-casting industry for many years and has accumulated rich experience and expertise. Our team of professionals possess highly skilled and knowledgeable staff in all aspects of die casting. Whether you need intricate designs or intricate parts, Mindwell has the capabilities to meet your needs.

Mindwell also offers value-added services such as machining, finishing and assembly. This comprehensive approach ensures that the finished product you receive will exactly meet your specifications.

2.Quality assurance

At Mindwell, quality matters. I have implemented strict quality control measures at every stage of the manufacturing process. From material selection to final inspection, each step is carefully monitored to ensure that the final product meets the highest standards.

Mindwell Corporation is ISO 9001 certified, demonstrating our commitment to continuous improvement and customer satisfaction.

3. State-of-the-art facilities

The Mindwell Company is proud of its state-of-the-art facility. We have invested in advanced machinery to ensure efficient and precise manufacturing processes. Our facility is equipped with the latest technology, allowing us to produce high-quality die-cast parts with tight tolerances.

Additionally, Mindwell Company regularly updates its equipment to stay at the forefront of industry advancements. This commitment to innovation enables us to provide our customers with cutting-edge solutions.

4.Customization and Flexibility

Every customer has unique needs, and Mindwell understands the importance of customization and flexibility. We work closely with our clients to understand our specific needs and provide tailored solutions.

Whether you need help with design optimization, material selection, or surface preparation, Mindwell Corporation has the expertise to guide you through the entire process. They are dedicated to providing solutions that not only meet your expectations but exceed them.

5. Competitive pricing

Mindwell offers competitive prices without compromising on quality. We understand the importance of cost-effectiveness and strive to provide value to our clients. By optimizing the manufacturing process and leveraging our expertise, we are able to offer competitive pricing for die cast parts.

In addition, Mindwell Company believes in transparency and honesty in pricing. We provide detailed quotes that clearly outline the costs involved, making sure there are no hidden surprises.

6.customer satisfaction

Customer satisfaction is at the heart of Mindwell’s business philosophy. We prioritize building long-term relationships with our customers by providing superior products and services. Our dedicated customer support team is always ready to resolve any questions or inquiries promptly.

Mindwell Corporation’s experience, expertise, commitment to quality, state-of-the-art facilities, customization options, competitive pricing and customer satisfaction make us an excellent choice. When you choose Mindwell Corporation, you can be confident that you are working with a reliable and trustworthy supplier that will provide quality die cast parts to meet your specific needs.