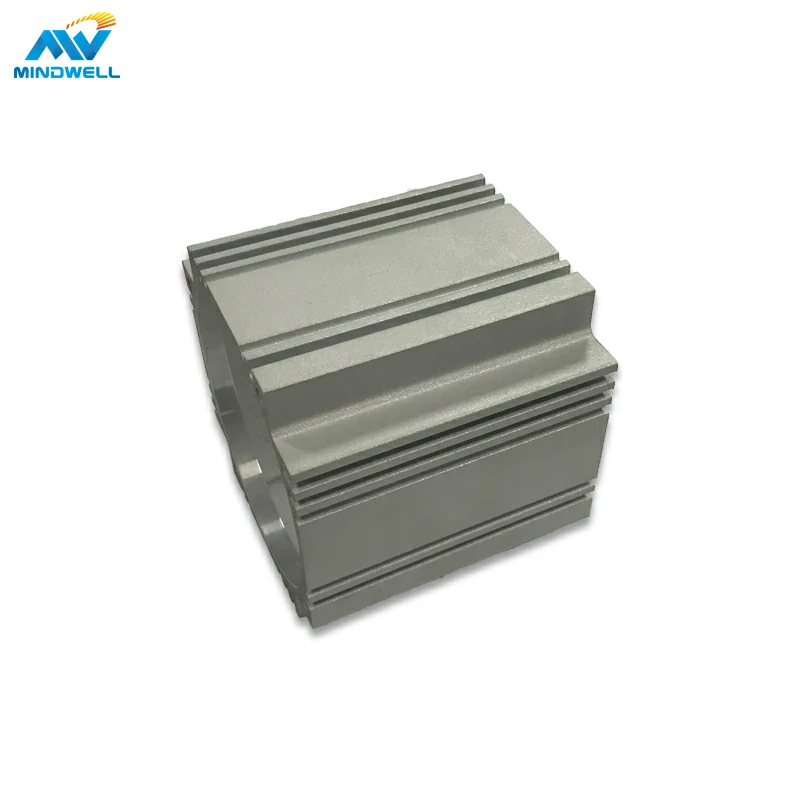

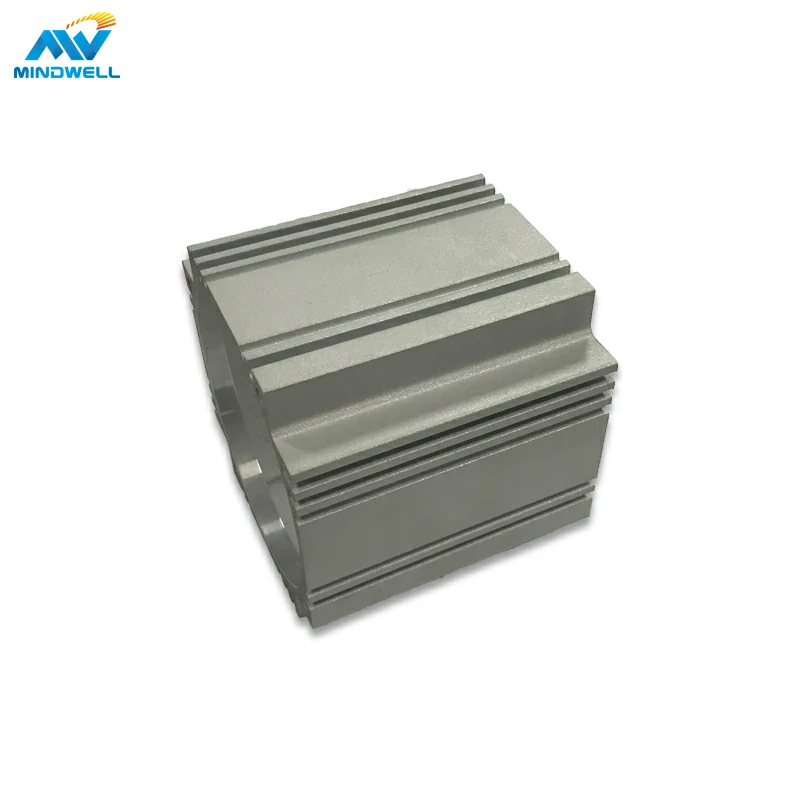

Aluminum electric motor housing is a type of motor housing that protects the motor body and serves as a component mounting bracket to protect the motor components from dust and damage. The aluminum alloy motor casing is produced by aluminum alloy die-casting. The hardness and heat dissipation properties of the aluminum alloy enable the motor casing to also dissipate heat or sound insulation.

We can custom design motor housings according to customer needs, and our expertise and advanced equipment will provide reliable and consistent functionality to the motor while maintaining good performance. Aluminum alloy motor housings are made solely from aluminum alloy materials, making them strong, durable and resilient. All aluminum alloy motor casings fit around your car motor like clothing, providing unmatched protection and heat dissipation.

Mindwell, as a professional aluminum die-casting manufacturer, our company has multiple die-casting machines and equipment and has the ability to produce large-scale products. We have a team of engineers who can custom design the motor housing. Whether it is a fin-shaped or integrated housing die-cast, we can customize it according to the usage requirements. Motor housings can also be produced through standardized customization or low-volume production equipment.

Aluminum motor housing material

- A356 aluminum alloy:A356 aluminum alloy has the characteristics of high strength, high toughness, good resistance to thermal expansion and good corrosion resistance. The density of this material is 2.7g/cm³, and it is mainly used in high-end aluminum motor casings, automobile wheels and other fields.

- ADC12 aluminum alloy:ADC12 aluminum alloy has good mechanical properties and thermal fatigue resistance, and its density is 2.73~2.75g/cm³. It is mainly used in fields such as motors, automobile parts and building materials.

- 6061 aluminum alloy:6061 aluminum alloy has excellent corrosion resistance and heat resistance, and its density is 2.7g/cm³. It is mainly used in fields such as aerospace, electronics, automobiles and machinery equipment manufacturing.

- 5083 aluminum alloy:5083 aluminum alloy is an aluminum alloy material with high strength, corrosion resistance, and outstanding heat resistance, with a density of 2.66g/cm³. It is mainly used in fields such as shipbuilding, shipbuilding and ocean engineering.

To sum up, the commonly used aluminum materials for aluminum motor casings are A356 aluminum alloy, ADC12 aluminum alloy, 6061 aluminum alloy and 5083 aluminum alloy. Different materials have different characteristics and application fields. Choosing the appropriate aluminum material can better protect the motor and extend its service life.

Advantages of aluminum motor housings

- Good heat dissipation: During the working process of the motor, energy will be converted, and a large part of it is converted into heat. We know that aluminum has good heat dissipation, and can quickly cool down the motor and last longer.

- Lightweight: Metal aluminum is very light. Using aluminum motor housing can reduce the weight of the entire motor. Easy to install and transport.

- Aluminum has good moldability. Aluminum has a higher elongation than iron, is easy to process, and has good plasticity. It can be made into a variety of shell shapes that meet the requirements, such as fin shape.

- The aluminum alloy motor casing can also reduce the vibration of the motor, reduce the noise, and has waterproof, dustproof, anti-corrosion and other protective functions.

Aluminum motor housings have good load-bearing capacity and heat dissipation effects and are widely used in industrial motors, automotive motors and other industries. Using aluminum as motor housings has great advantages.

Surface treatment options for motor housings

- Surface brushing treatment:Metal drawing is a manufacturing process in which lines are repeatedly scraped out of aluminum sheets using sandpaper.

- Electroplating electrophoresis treatment:Electroplating electrophoresis uses electrolysis to attach a metal film to the surface of metal or other material parts to prevent metal oxidation (such as rust) and improve wear resistance, conductivity, reflectivity, and corrosion resistance (copper sulfate etc.) and enhance aesthetics.

- Surface grinding and polishing treatment:The polishing process is mainly divided into: mechanical polishing, chemical polishing, and electrolytic polishing. The aluminum motor casing is mechanically polished + electrolytic polished to achieve a stainless steel mirror effect.

- Surface sand blasting and shot blasting treatment:Using the impact of high-speed sand flow to clean and roughen the metal surface can achieve a certain degree of cleanliness and different roughness on the surface of the workpiece, thereby improving the mechanical properties of the workpiece surface, thereby improving the fatigue resistance of the workpiece and increasing its and The adhesion between coatings extends the durability of the coating and is also beneficial to the leveling and decoration of the coating.

- Anodizing:The most commonly used surface treatment for aluminum shells is anodizing. Anodizing can not only solve the defects of aluminum surface hardness, wear resistance, etc., but also extend the service life of aluminum and enhance its aesthetics. It is the most common surface treatment process among all aluminum shells. It is commonly used and is the most mature process.

Why choose us

- One-stop service: We not only focus on the die-casting manufacturing of aluminum alloy products, but also cover multiple fields such as aluminum alloy extrusion and processing, and aluminum die-casting mold development. This diversified production capacity enables us to meet the diverse needs of our customers and provide customers with one-stop comprehensive solutions.

- Advanced equipment and processes: We have a series of special production equipment, such as die-casting machines, shot blasting machines, ultrasonic cleaning machines and anodizing surface treatment equipment. We are also equipped with CNC lathes, CNC milling machines, multi-function drilling machines and other general precision machines. process equipment. These modern equipment and processes ensure the high quality and production efficiency of the products.

- Mature technology and experience: After years of continuous improvement and optimization, our company’s production technology has a mature and complete production process, ensuring product consistency and reliability. Our team has extensive experience and is able to handle a variety of challenges and your needs.

- Advanced Quality Control: We have advanced product testing equipment to ensure that our products meet high quality standards. We have established a sound and comprehensive quality assurance system to ensure that every product meets or exceeds customer expectations.

- Customer customization service: We are willing to provide samples, drawings, and fine processing according to customer requirements to produce qualified finished products. We pay attention to our customers’ needs and are committed to providing personalized solutions.

In short, our company has extensive experience, advanced equipment and processes, and diversified production capabilities in the field of aluminum alloy manufacturing. These factors make us your ideal partner, able to meet your various needs and provide high-quality High quality aluminum alloy housing products.