Компания Mindwell специализируется на производстве высококачественных деталей, отлитых под давлением из цинкового сплава, для широкого спектра отраслей промышленности и применений. Наш опыт в технологии литья под давлением в сочетании с нашим стремлением поставлять исключительную продукцию делает нас предпочтительным выбором для предприятий, которым нужны надежные и долговечные детали.

Что такое литые детали из цинкового сплава?

Детали из цинкового сплава, полученные методом литья под давлением, представляют собой компоненты, изготовленные путем заливки расплавленного цинкового сплава в форму и его застывания. Этот производственный процесс, известный как литье под давлением, позволяет получать детали с отличной точностью размеров, сложным дизайном и превосходной отделкой поверхности.

Преимущества литья под давлением деталей из цинкового сплава

Детали, отлитые под давлением из цинкового сплава, обладают многочисленными преимуществами по сравнению с деталями, изготовленными из других материалов:

- Прочность и долговечность: Детали, отлитые под давлением из цинкового сплава, известны своей исключительной прочностью и долговечностью, что делает их пригодными для различных применений, требующих надежных компонентов.

- Легкий вес: Несмотря на свою прочность, детали из цинкового сплава, полученные методом литья под давлением, имеют относительно небольшой вес, что делает их идеальными для применения в тех областях, где снижение веса имеет решающее значение.

- Устойчивость к коррозии: Цинковые сплавы обладают превосходными антикоррозийными свойствами, обеспечивая долговечность литых деталей даже в суровых условиях.

- Высокая точность: Технология литья под давлением позволяет изготавливать детали сложной формы и замысловатого дизайна с высокой точностью, обеспечивая соответствие деталей требуемым техническим характеристикам.

- Экономичность: Детали, отлитые под давлением из цинкового сплава, являются экономически выгодным решением по сравнению с деталями из других материалов, поскольку процесс литья под давлением обеспечивает эффективное производство и сокращает отходы материалов.

Области применения литья под давлением деталей из цинкового сплава

Детали, отлитые под давлением из цинкового сплава, находят применение в различных отраслях промышленности, включая:

- Автомобиль: Наши литые детали из цинкового сплава широко используются в автомобильной промышленности для изготовления таких компонентов, как детали двигателя, корпуса трансмиссии и дверные ручки.

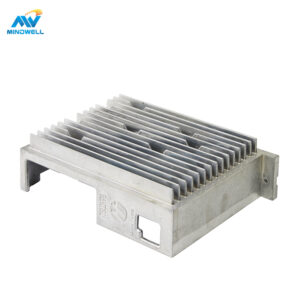

- Электроника: Отличная электропроводность цинковые сплавы что позволяет использовать их для изготовления электронных компонентов, включая разъемы, клеммы и радиаторы.

- Мебель: Детали, отлитые под давлением из цинкового сплава, широко используются в производстве мебельной фурнитуры, такой как ручки, ручки и петли.

- Приборы: От кухонных приборов до бытовой техники - детали из цинкового сплава, отлитые под давлением, используются в различных устройствах благодаря своей прочности, долговечности и эстетической привлекательности.

- Промышленное оборудование: Наши детали, отлитые под давлением из цинкового сплава, пользуются доверием в отраслях промышленности, где требуются надежные и долговечные компоненты для машин и оборудования.

Процесс литья под давлением цинкового сплава

Процесс литья цинкового сплава под давлением - это процесс, в котором литейная машина используется для впрыска расплавленного цинкового сплава в форму, и после застывания и охлаждения получается формованный продукт. Этот процесс широко используется при производстве различных изделий из цинкового сплава, таких как автозапчасти, корпуса электронного оборудования, бытовые товары и т.д.

Ниже приведена основная схема работы цинковый сплав процесс литья под давлением:

- Подготовьте формы и материалы: Выберите подходящую форму и подготовьте необходимые материалы из цинкового сплава.

- Нагрев материалов из цинкового сплава: нагрев материалов из цинкового сплава до соответствующей температуры плавления. Обычно температура плавления цинкового сплава составляет около 419℃.

- Открытие пресс-формы: Нагретый до расплавленного состояния цинковый сплав впрыскивается в форму.

- Запечатайте форму: Запечатайте форму, чтобы предотвратить вытекание цинкового сплава в процессе застывания.

- Охлаждение и затвердевание: Дайте цинковому сплаву остыть и затвердеть в пресс-форме, чтобы сформировать изделие нужной формы.

- Формование: извлечение отформованного изделия из формы.

- Постобработка: Необходимая постобработка формованных изделий, такая как шлифовка, полировка и т.д., для улучшения их внешнего вида, качества и эксплуатационных характеристик.

Следует отметить, что такие параметры, как температура, давление и время в процессе литья цинкового сплава под давлением, оказывают влияние на качество продукции, поэтому в процессе работы эти параметры должны строго контролироваться. В то же время, чтобы обеспечить качество продукции и эффективность производства, необходимо регулярно проверять и обслуживать машины для литья под давлением, пресс-формы и другое оборудование.

Почему выбирают нас?

Когда речь идет о деталях для литья под давлением из цинкового сплава, выбор правильного производителя имеет решающее значение. Вот почему вы должны выбрать Mindwell:

- Опыт и знания: Имея многолетний опыт работы в отрасли, мы отточили свои знания в области литья под давлением цинковых сплавов, обеспечивая высочайшие стандарты качества в каждой производимой нами детали.

- Современное оборудование: Наши передовые производственные мощности оснащены самыми современными технологиями и оборудованием, что позволяет нам поставлять прецизионные детали, которые точно соответствуют вашим техническим требованиям.

- Обеспечение качества: Мы осуществляем строгий контроль качества, чтобы гарантировать, что каждая деталь, отлитая из цинкового сплава под давлением, не имеет дефектов и соответствует самым высоким стандартам качества.

- Персонализация: Мы понимаем, что каждое применение имеет уникальные требования. Именно поэтому мы предлагаем варианты индивидуальной настройки, чтобы адаптировать наши детали из цинкового сплава для литья под давлением к вашим конкретным потребностям.

- Своевременная доставка: Мы гордимся своей способностью доставлять заказы точно в срок, обеспечивая бесперебойную работу вашего производственного графика.

- Конкурентные цены: Наше стремление к эффективности и рентабельности позволяет нам предлагать конкурентоспособные цены без ущерба для качества.

Свяжитесь с нами

Если вам нужны высококачественные детали для литья под давлением из цинкового сплава, обратите внимание на компанию Mindwell. Свяжитесь с нами сегодня, чтобы обсудить ваши требования, и наша команда экспертов будет рада помочь вам.