Aluminum die casting service is a service that provides customers with customized aluminum alloy parts and products through the aluminum die-casting process. Aluminum die casting is an effective manufacturing process that creates pieces with intricate designs by injecting molten aluminum alloy into a mold that has been carefully made and then using high pressure to cool and solidify it.

The lightweight, high-strength qualities of aluminum alloys, cost-effectiveness, and efficient manufacture of complexly formed components are some of the main benefits of aluminum die casting services. Because of this, die casting of aluminum is the technique of choice for producing intricate components made of aluminum alloy in numerous industries.

Aluminum die casting service content:

- Product Design: Collaborates with clients to create unique product designs by thoroughly comprehending their requirements. Technical parameters, form, size, yüzey işleme, and other topics may be discussed in this context.

- Professional engineering help should be provided for material selection, kalıp tasarımı, manufacturing process optimization, and other related tasks. Making ensuring the finished product satisfies both client demands and strict quality standards is the goal.

- Mold Fabrication: To guarantee that items are manufactured in accordance with design requirements, fabricate unique die-cast aluminum molds. An important phase in the aluminum die casting process is the design and manufacture of the mold.

- Production and processing: The chosen aluminum alloy material is melted, pumped into the mold, and rapidly solidified under high pressure using the aluminum die-casting method. This guarantees the items’ outstanding surface quality and high degree of accuracy.

- Quality Control: To track and identify each stage of the manufacturing process, put in place a stringent quality control system. By using cutting-edge testing apparatus, we guarantee that the finished product satisfies both client requirements and industry norms.

- Surface treatment: To satisfy client needs for appearance, corrosion resistance, and other performance features, a variety of surface treatment methods, including anodizing, spraying, electrophoretic coating, etc., are available.

- Tailored solutions: The primary goal of aluminum die casting services is to provide clients tailored solutions that address the requirements of various sectors and use cases. This might have to do with special-purpose parts, high-performance specifications, or lightweight design.

What are Aluminum Die Casting Services?

High-quality, intricate aluminum components are manufactured via the use of aluminum die casting services. Melted aluminum is injected into a mold cavity during this procedure, where it solidifies and takes on the form of the mold. The end product is an accurate and long-lasting aluminum part that finds use in a wide range of sectors, such as electronics, automotive, and aerospace.

Alüminyum Basınçlı Dökümün Avantajları

Compared to other production techniques, alümi̇nyum döküm has the following benefits:

- Strong and Lightweight: Due to its exceptional strength-to-weight ratio, aluminum is a great option for applications requiring both strong and lightweight characteristics.

- Complex Geometries: Die casting makes it possible to produce pieces with tight tolerances that are both precisely fitted and functional.

- High Efficiency: By enabling high production rates, the die casting technique lowers manufacturing expenses and time.

- Excellent Surface Finish: There is no need for further finishing procedures since aluminum die cast pieces have a smooth, visually pleasant surface finish.

- Good Thermal Conductivity: Aluminum has a high heat-dissipation efficiency, which makes it a good choice for applications requiring efficient thermal control.

Our Aluminum Die Casting Services

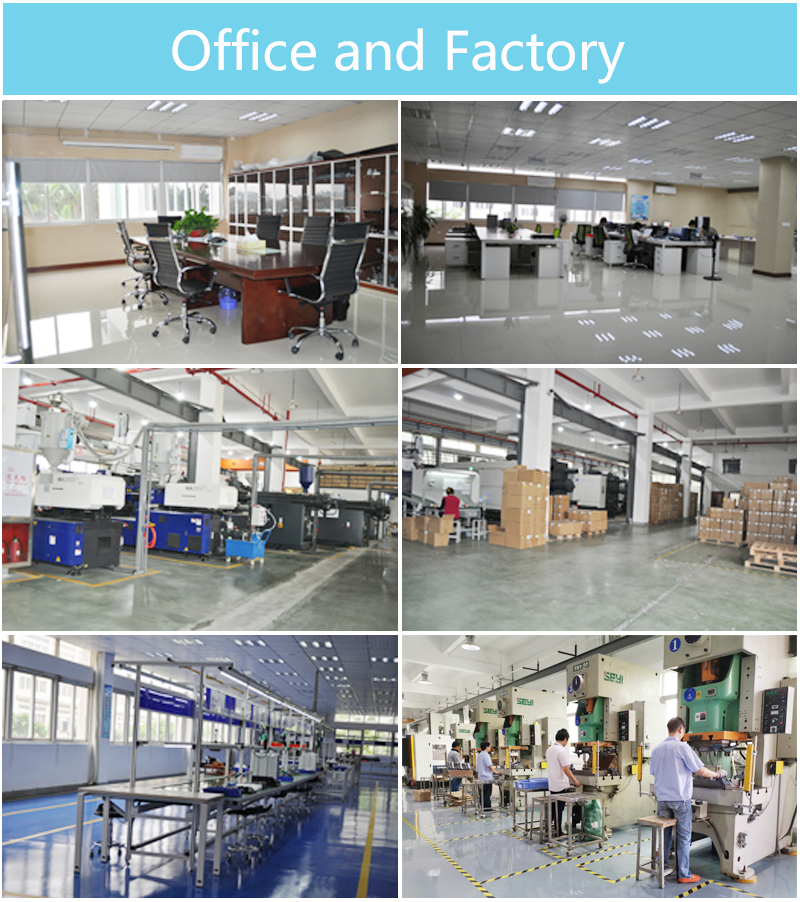

in Mindwell, we’re experts in offering premium aluminum die casting services to satisfy our customers’ various demands. Our skilled staff and cutting-edge facilities enable us to produce precisely engineered aluminum components that adhere to the strictest industry requirements.

Support for Engineering and Design

In close collaboration with customers, our team of talented engineers and designers optimizes product designs for the die casting process. To guarantee effective mold design and fabrication, we make use of the most recent CAD/CAM software.

Making Molds

Because we have the ability to make molds in-house, we can make unique molds that are suited to the particular needs of every project. Our expert mold makers create high-quality molds that ensure precise and reliable component manufacture by using cutting-edge technology.

Die Casting of Aluminum

Our cutting-edge die casting equipment enable us to effectively manufacture aluminum components with a range of sizes and intricate designs. Our knowledgeable operators keep a careful eye on the procedure to guarantee ideal casting conditions and reduce flaws.

Finishing and Machining

We provide secondary machining and finishing services to further improve the items after the die casting process. We can obtain exact measurements and tight tolerances thanks to our CNC işleme skills. Additionally, we provide a variety of finishing choices, including as plating, anodizing, and powder coating, to improve the aluminum components’ resilience and aesthetic appeal.

Assurance of Quality

Our first concern is quality. Throughout the whole production process, we use stringent quality control procedures to guarantee that every aluminum component satisfies the necessary requirements. In-depth testing and inspections are carried out by our committed quality assurance team to ensure the best possible product performance and quality.

Why Choose Our Aluminum Die Casting Services?

You may anticipate the following when you work with Mindwell on your alümi̇nyum döküm needs:

- Excellent aluminum components that either match or surpass industry requirements

- Quick turnaround to fulfill the deadlines for your projects

- Competitive pricing helps increase the efficiency of your costs

- Professional technical assistance and direction along the procedure

- Adaptability to handle both modest and massive production runs

- dedication to ecologically beneficial and sustainable methods

Get in touch with us right now to find out more about our aluminum die casting services and how we can assist in realizing your project.