Customized Photovoltaic Energy Storage Parts

Many spare parts of photovoltaic energy storage use die-casting, CNC machining, injection molding, 3D printing and other processing techniques. We can guide you through the design process, recommend suitable manufacturing methods, and ensure that photovoltaic and energy storage components meet your specific requirements.

- The most advanced processing technology and technology

- Various detection tools

- Diverse equipment, different tonnage to meet customized requirements

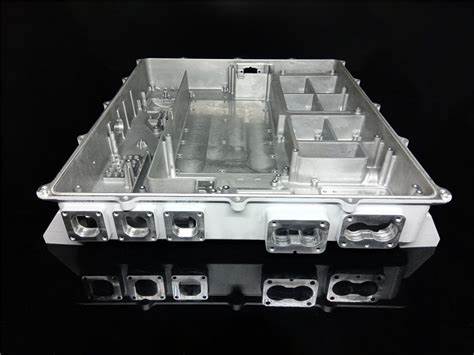

Die casting parts for photovoltaic energy storage

With the development of photovoltaic energy storage industry, OEM die casting makes die castings bigger and bigger, the value of single castings is getting higher and higher, and the requirements for casting quality are getting higher and higher, which affects the mechanical properties and appearance of castings. Dimensions, product accuracy, etc. have brought new challenges. In addition to improving the die-casting production process and technology, our company also uses auxiliary testing equipment to ensure that defective products do not flow into the next production process. It is an important guarantee for photovoltaic The quality of energy storage die castings is guaranteed.

Application:

- Inverter housing

- Battery case

- Brackets and Fixtures

- Entrance boxes and cable glands

- heat sink

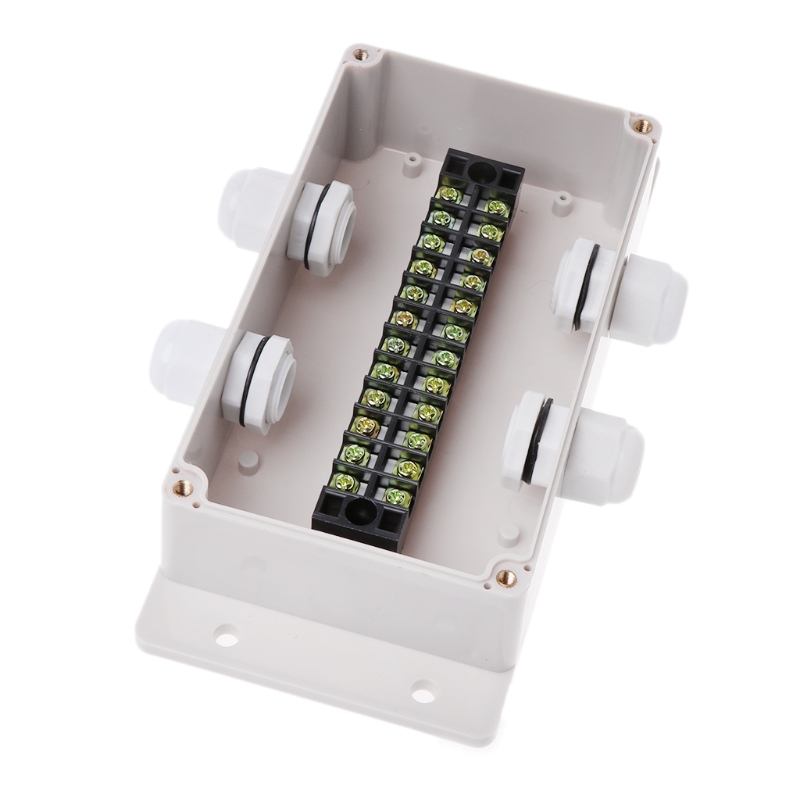

CNC machining

CNC machining is a versatile process that uses computer-controlled machines to shape and cut materials. It is suitable for producing parts with complex geometry and high precision. CNC machining can be used to manufacture photovoltaic energy storage components made of various materials such as aluminum, steel or plastic.

Application of CNC parts in photovoltaic energy storage

- Solar Mounting Parts

- inverter parts

- battery box parts

- Smart Controller Parts

- Junction box parts

- radiator parts

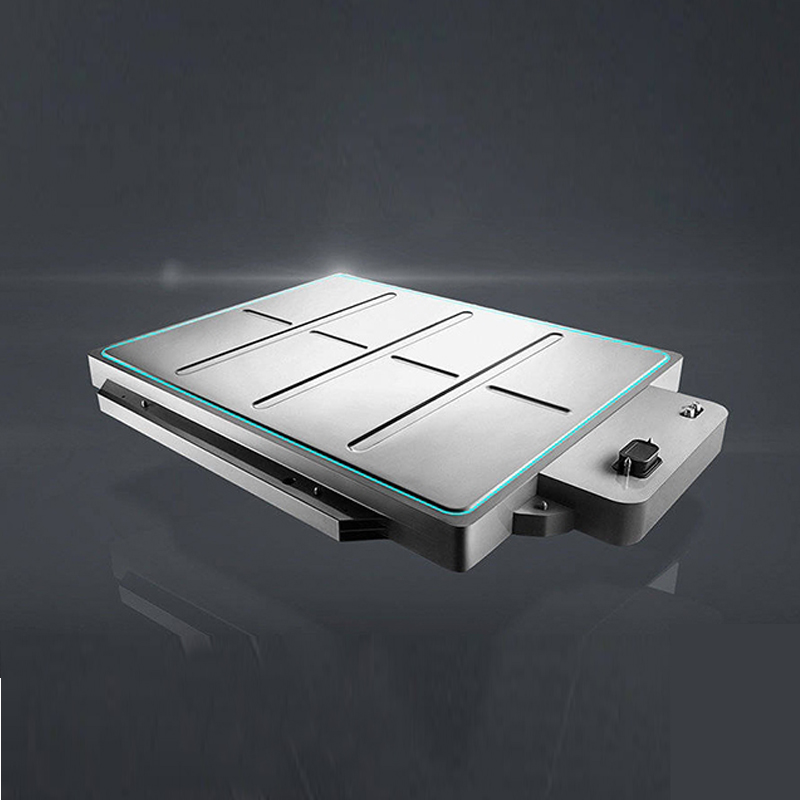

Injection molding

Injection molding is a popular manufacturing process for high-volume production of plastic parts. It involves injecting molten plastic material into a mold cavity, which then cools and solidifies to form the desired part. Injection molding can be used to produce custom plastic components for photovoltaic energy storage systems, such as battery housings or housing components.

Application of injection molded parts in photovoltaic energy storage

- Battery case

- Incoming boxes and connectors

- Inverter enclosures and accessories

- Brackets and Fixtures

- Cooling fan and heat sink

3D printing/additive manufacturing

3D printing, also known as additive manufacturing, is a process that uses computer-controlled machines to build parts layer by layer. It allows the creation of complex geometries and custom designs. 3D printing can be used to produce prototypes, small batches and even final components of photovoltaic energy storage systems. Materials used in 3D printing include various plastics, metals and composites.

Get Started Now with Customized Photovoltaic Energy Storage Parts According to Your Needs!

Choose our customized photovoltaic energy storage parts

When customizing photovoltaic energy storage components, our company has a variety of process technologies, has its own die-casting, injection molding workshop, and also has CNC processing and 3D printing technology, we can meet your customization needs.