Good Quality And Fast Delivery

Custom Parts Manufacturer

MINDWELL is a manufacturer that provides die-casting, injection molding, and CNC processing. The company has advanced production equipment and professional technical personnel for one-to-one connection.

Our Manufacturing Services

MindWell provides on-demand manufacturing services, from product design to batch production, debugging and assembly. With our professional engineering team and advanced equipment, we have strong manufacturing capabilities. Our after-sales team communicates with customers in real-time, providing comprehensive services to help customers achieve customized production of the required parts.

Die Casting

We utilize advanced die-casting machines and adhere to rigorous die-casting processes to ensure the quality of your custom die-casting parts. Our focus is on producing aluminum and zinc alloy die castings and precision machining workpieces.

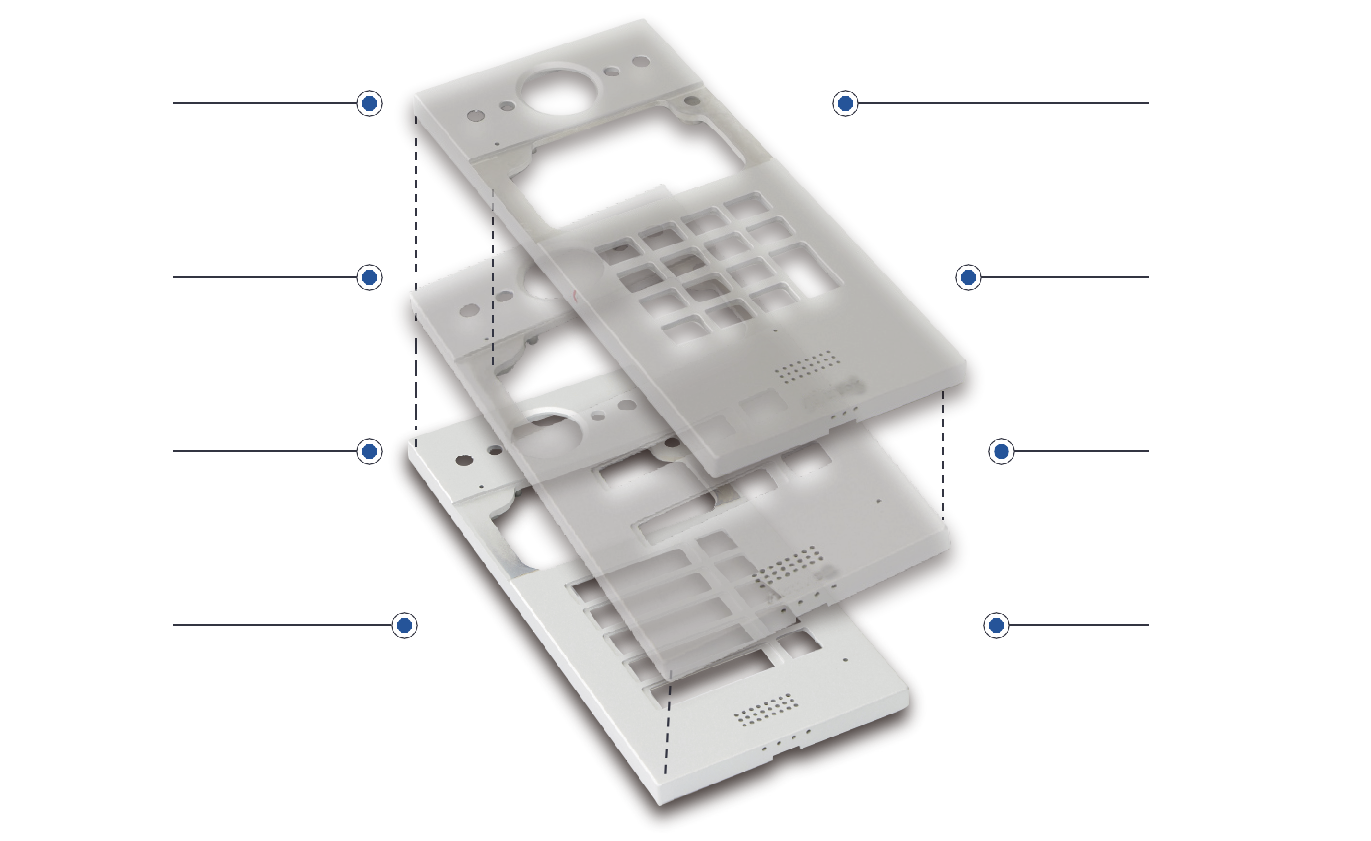

Injection Molding

MINDWELL offers injection molding machines ranging from 50 to 1,300 tons, catering to your customized requirements for injection molded parts of varying shapes and sizes. We provide a one-stop injection molding service

CNC Machining

We specialize in processing high-precision and high-accuracy customized parts utilizing our CNC machines, milling and turning. We also offer secondary finishing services to customize CNC parts.

Mold Design

our engineers will provide you with professional advice to design and manufacture production molds in a cost-effective manner. Our molds are highly precise and can be used for prolonged periods of time.

3D Printing

3D printing services can manufacture complex parts, create prototypes and models, or produce personalized products just from design files, and can perform custom operations, which can save you time and costs.

Assemble

MINDWELL has a unique assembly line that can provide product debugging and assembly services to customers. We offer the added convenience of accepting accessories at our factory for assembly, packaging, and shipping directly to you.

OUR COMMITMENT

Years of hard work and fortitude, combined with the diversification of our manufacturing capabilities, has helped MINDWELL PRECISION MANUFACTURE win the trust of prestigious companies around the world and to grow the MINDWELL brand into other business opportunities. Our record of success is anchored by an unwavering commitment to ethical behavior and the preservation of human rights and environmental resources to the greatest extent possible.

MINDWELL’s management brings a wealth of knowledge in product design, manufacturing, assembly and product validation, all of which are governed by stringent, current and proven methods that ensure consistent quality in every product we produce. Being a global company, we are also regulated by an ever more complex regulatory environment that translates into products that are complaint with the most stringent applicable regulations, regardless of where the product is sold.

Each of us at MINDWELL shares in the responsibility to uphold the standards of honor and integrity that have defined MINDWELL over its history. We also share in a common commitment to self-improvement, quality and innovation, and to continuously seek new ways to add-value and enhance mutually beneficial client relationships.

Epro Ruan

Chief Executive Officer

MINDWELL GUIDING PRINCIPLES

- MINDWELL is dedicated to serving its customers, employees, and investors by doing business the right way. That means we act in a lawful, ethical and trustworthy manner.

- Continuous Improvement and Innovation are central to our pursuit of excellence. Our Quality focus is aligning the voice of the process with the voice of the customer.

- Customer Focus aligns our organization, resources, and strategies to exceed total customer satisfaction. We continuously seek new ways to add-value, develop, maintain, and enhance mutually beneficial client relationships.

- Employee Involvement is essential to creating an environment in which each employee is willing and able to contribute his or her efforts, knowledge, and ideas to achieve the company's mission and strategy. MINDWELL's employees share the position that “customer satisfaction ion” is the major criteria for success measurement.

Demonstrate the company's capabilities with numbers

MINDWELL'S CUSTOM PARTS SERVICE

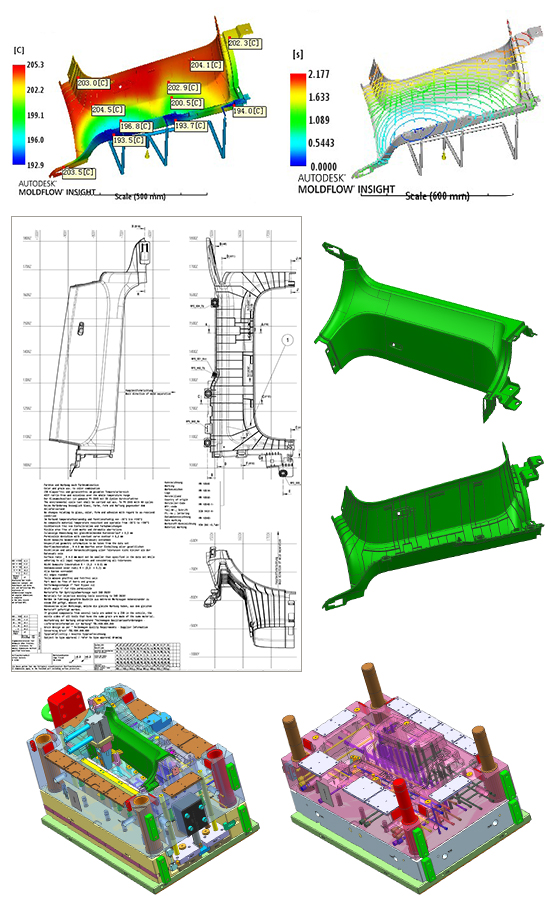

Our company as a professional custom die casting service manufacturer, injection molding service manufacturer, we have rich experience in custom parts. The picture on the left is our design drawing case, and the bottom is our custom process

Get Instant Quote

Formulate product design plans according to requirements and material selection, including structural shape, size, and manufacturing process.

Mold manufacturing and sample sending

Through CAD/CAM software design, strict Moldflow and DOE analysis and the most advanced measurement technology to produce a mold that meets the product design plan,

Mass production processing

After confirming that the sample is correct, the formal mass production process will begin. The produced die-casting parts need to undergo strict quality inspection to ensure that they meet the requirements of customers.

Quality Creates Trust

High-quality parts come from ingenious casting,Every meticulous step is taken to ensure the quality of the parts customized according to your specifications.

Latest Blog Posts

Regularly share articles and exchange experience in the parts manufacturing industry with everyone, and learn and grow together

The Importance of Aluminum Heat Sink Enclosure in Heat Management for Electronic Components

Aluminum heat sink enclosures are highly sought after due to their excellent thermal conductivity properties. Aluminum has a high thermal conductivity, which means it can

What is aluminum die casting? Detailed process introduction

Aluminum die-casting is a process in which aluminum alloy is heated to a liquid state and injected into a die-casting mold for cooling and forming.

What Steps Can Enhance the Aesthetics of Products in High Pressure Aluminum Die Casting?

High pressure aluminum die casting is a popular production technique with several benefits, such as efficiency, affordability, and the capacity to precisely construct intricate designs.