You want to find a professional aluminum die casting manufacturer through Google search, our company Mindwell is a good choice for you, because we can provide you with professional customized die casting services, we have rich experience in aluminum die casting, currently our company specializes in exporting die casting parts to various countries around the world. Our biggest advantage is professionalism and service. Professionalism means that our engineers with more than ten years of experience will connect with you one-on-one, and our company also has advanced die-casting technology and equipment. Good service is that we have young sales team, warm and active. As well as our company’s project management, we will contact you in real time from pre-sales to after-sales. If you are looking for an fundición de aluminio a presión manufacturer to help you customize the parts you want, let me introduce our company to you.

About MindWell Company

MindWell was established in 2012. The company has been focusing on the R&D and production of precision die-casting in the aluminum alloy and zinc alloy industries. After years of development, it has a production base of 9,800 square meters and 120 employees, including 32 professional technical teams and 65 production teams. It has gradually formed a pattern of production capacity dominated by die-casting technology;

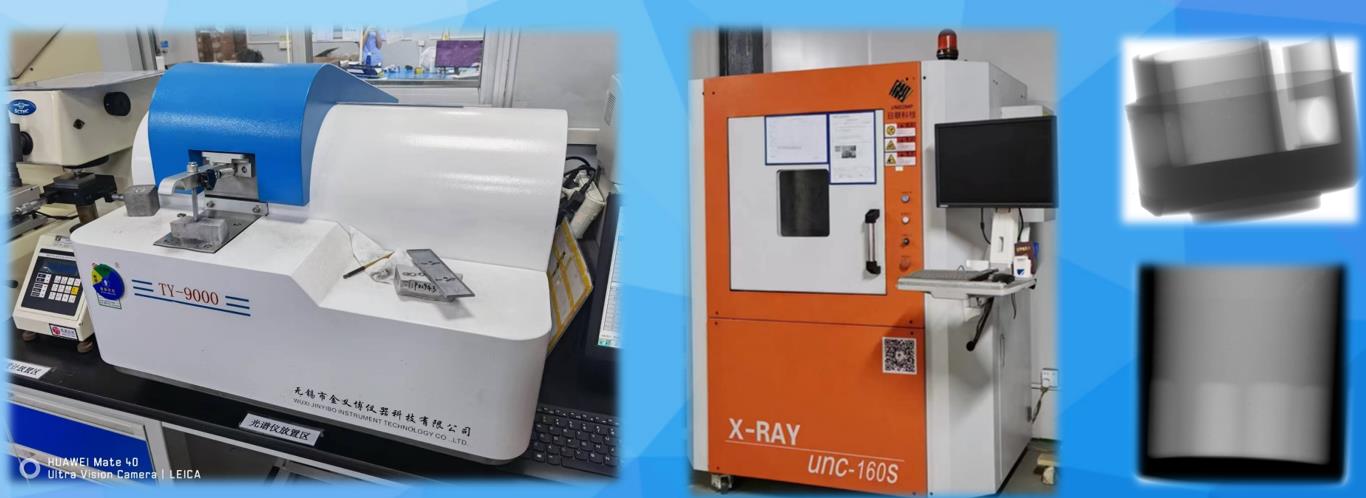

MINDWELL has 15 die casting machines ranging from 50 tons to 500 tons. It has advanced mold manufacturing equipment, three-coordinate measurement, advanced CAE mold flow analysis software in the industry, ERP management system, X-RAY optical-mechanical defect detection, material spectral analysis, etc.

Our company’s values are: “Quality first, customer service, truth-seeking and innovation, forge ahead”.Our company’s vision is: ”Become the world’s leading hardware manufacturer and help the global industrialization process.

our capabilities

Tooling

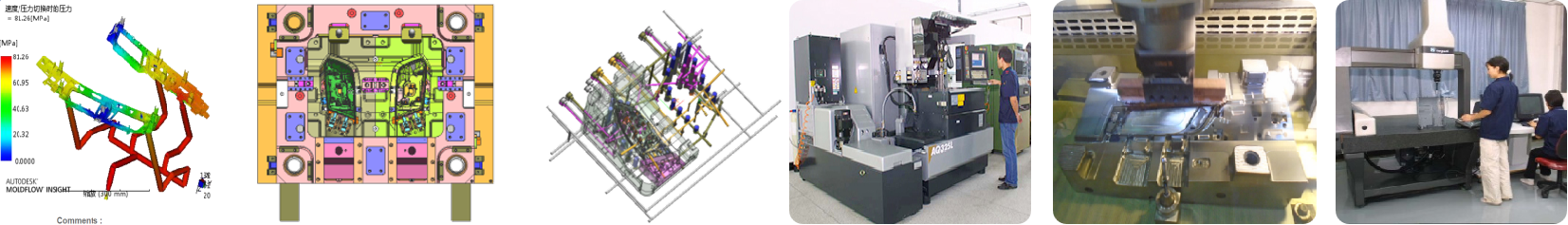

MINDWELL provides a full range of services, including design, manufacture and verification of prototypes and commercial tools, providing customers with one-stop solutions.

- We use advanced technologies and tools in the field of mold design and manufacturing, including computer-aided engineering (CAE), computer-aided design (CAD), precision computer-aided manufacturing (CAM), strict Moldflow analysis and design of experiments (DOE), etc. These tools ensure a high degree of precision and reliability in our mold design and manufacturing process.

- Our manufacturing capabilities cover die casting molds and 2K molds. At the same time, we are also good at using advanced molding technologies, such as Injection Molding & Decoration (IMD), Restricted Compression Thermoforming (RHCM), Liquid Silicone Molding and Zinc/Aluminum Die Casting. These technologies provide customers with more design and material options for their products to meet different application requirements.

- As of now, we have successfully produced more than 10 tons of molds, which reflects our rich experience and strength in mold design and manufacturing. We are able to deal with projects of various sizes and complexities, and provide customers with high-quality and efficient mold solutions.

Custom Die casting production

- MINDWELL adopts advanced die-casting machines in the field of die-casting, which includes famous brands such as FANUC, Yizhumi and ZHENGAO.

- We focus on aluminum alloy and zinc alloy die-casting production, able to provide customers with high-quality die-casting parts. In addition to die-casting production, we also have precision machining equipment capable of precision machining die-casting parts to ensure that the size and shape of each part meet stringent requirements.

- We also offer a variety of surface treatment options to suit our customers’ needs. These surface treatments include, but are not limited to, painting, anodizing, plating, and coating, etc., and can provide parts with corrosion resistance, wear resistance, and aesthetics.

- Our die casting machine capacities range from 50 tons to 500 tons, which means we can meet project requirements of all sizes and complexities. Whether it is small batch production or large-scale mass production, we are able to provide efficient and stable die casting services.

- In the production process, we can choose manual or automatic production according to the needs of customers. Manual production is suitable for small batches and items with special requirements, while automated production can improve production efficiency and consistency and is suitable for large-scale batch production.

Aluminum Die Casting Product Range

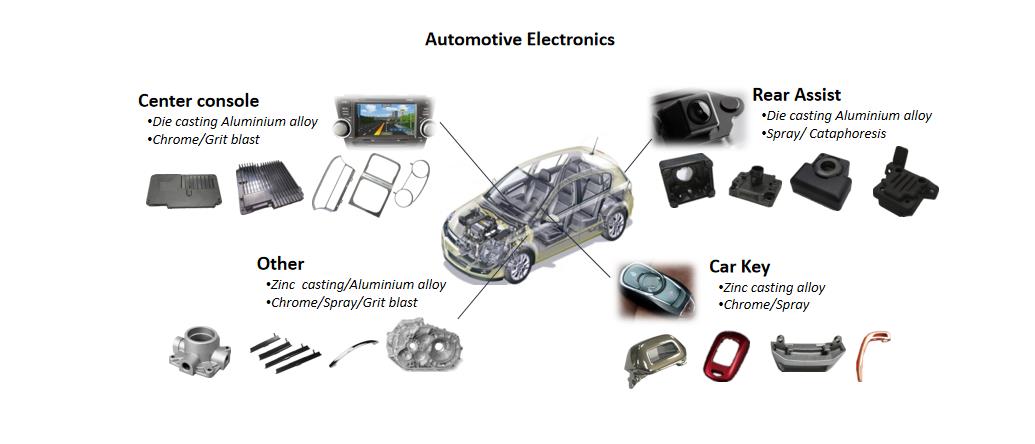

Automotive Electronics

The automobile industry is the industry where we produce the most aluminum die-casting parts. In current automobile manufacturing, many parts are made of aluminum die-casting. Such as central control, backup camera housing, car keys and engine parts, cylinder head, gearbox housing, crankcase, intake manifold, etc.

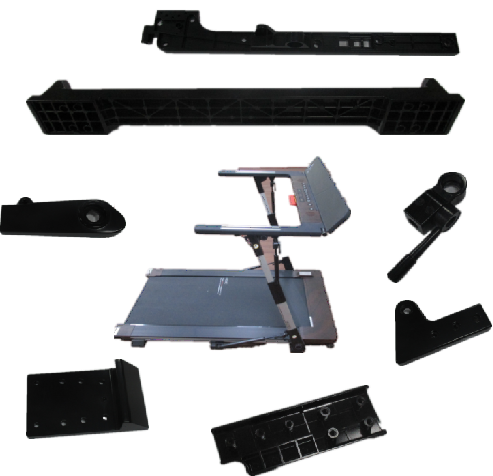

Gym equipment

Aluminum die castings are used in many fitness equipment, because aluminum die castings have hard strength and stability, and die castings are used in fitness equipment, such as treadmills and sports bicycles.

Muebles

Die-casting parts are also used in many places in furniture, such as table fixing and connection positions. Accessories for outdoor tables and chairs and other furniture die-casting parts.

other parts

Other industries such as construction industry, ship engineering, as long as aluminum die casting is available, we can meet your customized needs.

Classic die casting case display

In this classic die-casting case presentation, we demonstrated our excellent mold design, hot runner technology and molding process, demonstrating our professional strength and innovation ability in the die-casting field.

Special testing equipment

In addition to conventional material testing and manufacturing testing, our company also introduces spectrometers and X-ray defect testing equipment, etc. Our company attaches great importance to quality control testing. The introduction of these high-level equipment uses advanced technology and precision instruments to detect and analyze the composition and structure of materials to ensure that the products we produce meet strict quality standards and provide our customers with high-quality aluminum die-casting parts.

To sum up, we have shown you our company’s manufacturing capabilities, the range of products we can produce, and our company’s emphasis on quality control and mold design. We can provide you with professional aluminum die-casting services. If you are looking for a professional aluminum die-casting manufacturer, please contact us. I believe this is the beginning of our long-term cooperation.