Custom 3d Printing Service

3D printing services provide customers with various services such as prototyping, small batch production and customized product production. With advanced 3D printing equipment and a professional team, it can provide customers with a variety of businesses and solutions. Provide customers with more choices and flexibility, and help customers realize their ideas and quickly launch products to the market.

- Efficient and fast: 3D model printing service only takes hours or even minutes to complete the manufacture of a product.

- Low cost: 3D model printing services only need a 3D printer and a small amount of materials.

- Personalized customization: 3D model printing service can be customized according to the needs of customers.

Our Curriculum Overview

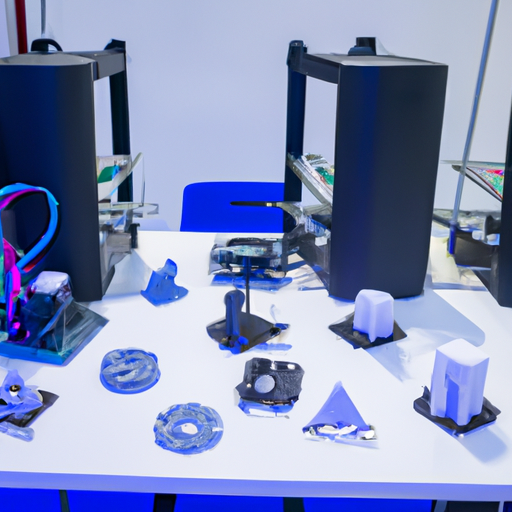

Our Online 3D Printing Processes

3D printing service is the process of transforming 3D models into physical objects, which provides customers with an efficient and fast manufacturing method. Design drawings can be directly turned into physical objects. This technology has a wide range of applications in medical, construction, automotive industries and other fields.

SLA 3D Printing

SLA is a rapid prototyping process. Those who use this technology place a high value on accuracy and precision. It can generate objects from 3D CAD data (computer-generated) files in just a few hours and is popular for its fine detail and precision.

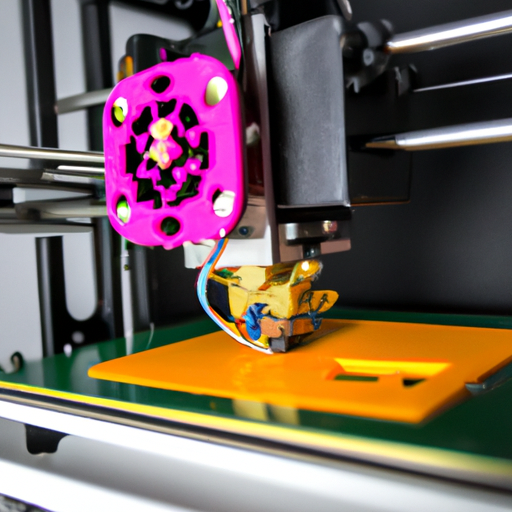

SLS 3D Printing

SLS is a 3D printing technique that uses high powered CO2 lasers to fuse particles together. Laser sintering of powdered metal materials (although it can also use other materials such as white nylon powder, ceramics and even glass).

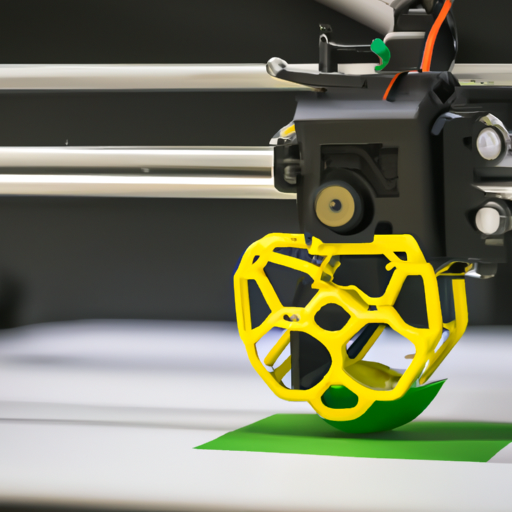

FDM Printing

FDM prints its 3D objects using production-grade thermoplastic materials. It is popular for producing functional prototypes, conceptual models, and manufacturing aids. It's a technique that creates accurate detail with an excellent strength-to-weight ratio.

Available Materials For 3D Printing

PLA, ABS, PETG materials for 3d printing. Prototypes and parts can be produced quickly, reducing product development cycles and production time.

PLA

PLA, a biodegradable plastic, is one of the most commonly used 3D printing materials. It is made of natural substances such as corn starch, which can be degraded into carbon dioxide and water, so it is friendly to the environment.

ABS

ABS is a common engineering plastic with excellent mechanical properties and thermal stability, so it is widely used in industrial fields.

PETG (polyester)

PETG is a high-strength and durable material that can be used in many fields, such as medical devices, tableware, etc.

Get Started Now with Custom 3D Printing Services According to Your Needs!

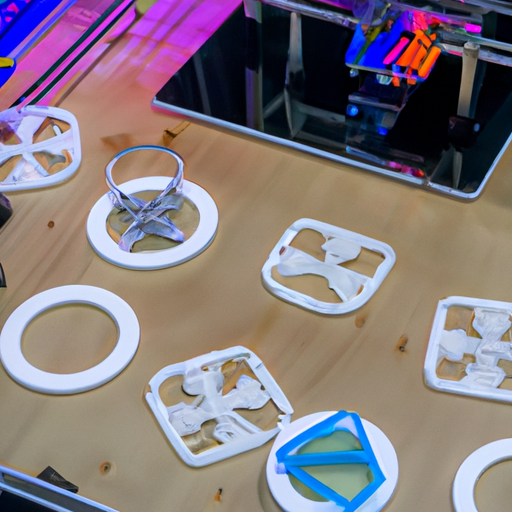

3D Printing Product Library

吾輩は猫である。名前はまだない。どこで生れたか頓と見当がつかぬ。何でも薄暗いじめじめした所でニャーニャー泣いていた事だけは記憶している。

Our 3D Printing Services For Various Applications

3D printing technology is a fast, flexible and precise manufacturing technology, and its application fields are very extensive, involving medical, aviation, automobile, construction, consumer goods and other fields

自動車産業

3D printing plays a very important role in the automobile industry. It can shorten the automobile research and development cycle, and at the same time save the cost of automobile production, and get rid of the dependence of traditional automobile manufacturing on molds.

Consumer Goods

The application of 3D printing technology in the field of consumer goods is mainly to produce personalized customized products, such as shoes, jewelry, glasses and so on. 3D printing technology can be used for rapid production according to the individual needs of consumers

Construction sector

The application of 3D printing technology in the construction field is mainly to produce architectural models and components. The use of 3D printing technology can realize the rapid construction and personalized design of buildings, reduce waste and save time and cost.

メディカル

3D printing technology can manufacture various medical devices with complex shapes, such as surgical guides, artificial joints, prosthetics, etc.Can be customized according to the individual needs of patients,Improves the accuracy and effectiveness of treatments.

3d printing advantages:

3D printing technology can quickly produce prototypes and parts, reducing product development cycles and production time.

3D printing can quickly customize products according to different needs, including personalized, small batch and low-cost production.

Traditional manufacturing techniques usually require cutting objects out of raw materials, while 3D printing can build the required parts directly on the model, reducing waste.

3D printing can create complex geometries and structures, making product design and construction more intuitive and visualized.

Compared with traditional manufacturing techniques, the cost of 3D printing is relatively low, and it is especially suitable for small batch production and personalized production.

3D printing can quickly iterate and test products, help designers discover and solve problems, optimize designs, and improve product quality and reliability.

お見積もり

射出成形のお見積もりは無料です。