Mold Design Services

MNW is a hardware manufacturing company with an experienced mold design team and excellent mold design capabilities. The molds we design are widely used in automobile molds, home appliance molds, electronic molds, medical equipment molds, etc.

- Precision Machining

- Mold maintenance rate is reduced to a minimum

- Provide 2D&3D drawings in various formats: DXT, DWG, IGES, STP, X-T, etc.

Mold Design Company

Our Mold Classification

In mold design, molds can be divided into various types according to different standards. At MNW, we provide automotive molds, home appliance molds, electronic molds, medical equipment molds, etc., classified by the field of use.

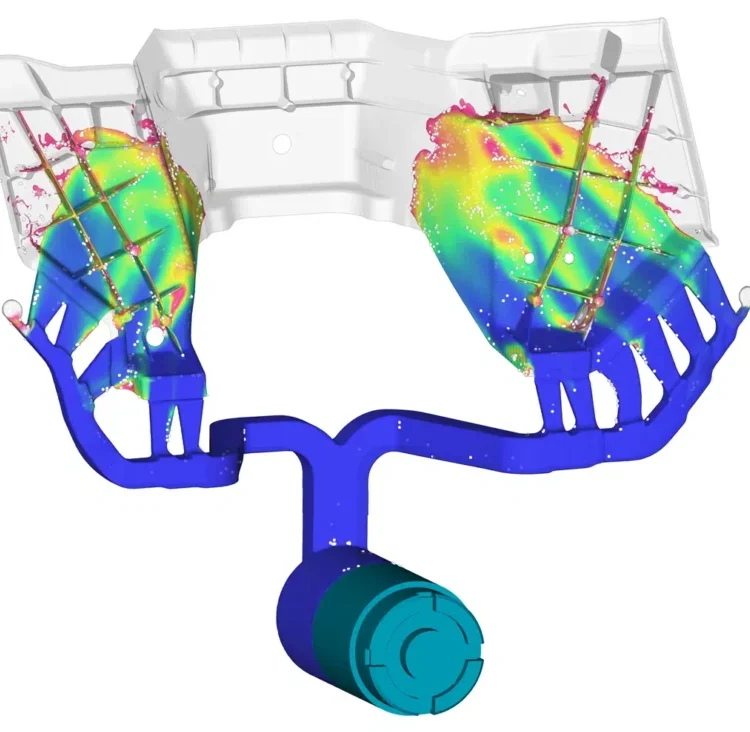

plastic injection mold design

Injection mold design needs to be selected according to the shape, size, material and production requirements of the part, so that the mold structure design is accurate and the production efficiency is high. At the same time, factors such as the life and cost of the mold must be considered.

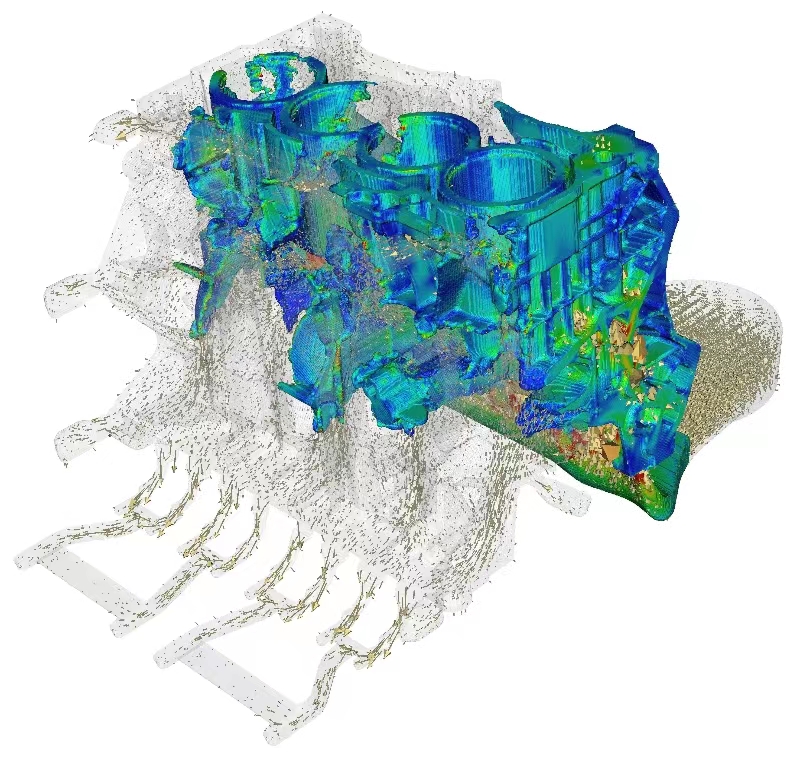

die casting mold design

The die-casting mold consists of two parts: cavity and core. The cavity is the shape of the final product and the core is the shape inside the product. The tool is designed to inject molten metal into the cavity and solidify into the desired shape. We can design according to your requirements.

Advantages of choosing MindWell for mold design

Our design team is experienced. As a mold design company, we have many years of experience and professional knowledge in the mold industry. We can fully understand the needs of customers and design from the perspective of customers.

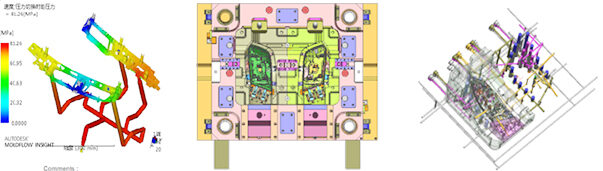

In mold design, every detail is carefully considered. We take into account many factors such as parting lines, ejection, cooling and all moving parts to ensure product quality and production efficiency. At the same time, our design is also aimed at reducing the possibility of mold repair and maximizing its life.

In order to ensure the design quality, we use internationally recognized professional software. We can provide 2D&3D drawings in various formats, including DXT, DWG, IGES, STP, X-T, etc., to meet the needs of different customers.

Get Started Now with Custom Tool Design Services According to Your Needs!

Mold Design Service Steps

During the mold design process, we strictly abide by the relevant standards and specifications to ensure the safety and reliability of the mold during use, and at the same time, we need to continuously improve and innovate in light of the actual situation.

1. Identify needs

Tell us the mold requirements and usage goals you need to design to determine the purpose of the design.

2. Prototyping

Conceive design proposals according to requirements, draw preliminary sketches, make models, and conduct tests and modifications.

3. Design model

According to the prototype design drawings and make models, simulate and test.

4. Mold making

Select and customize the necessary materials, carry out manufacturing processes such as CNC turning, fitter, etc., and manufacture molds that meet the requirements.

5. Testing and modification

Carry out systematic inspection and testing on the manufactured molds, adjust and modify them until they meet your requirements.

6. Production and implementation

Determine the production method and plan, put the mold into production, implement inspection and quality control, and ensure the quality of the final product.

Frequently Asked Questions

Mold design refers to the process of designing the mold structure, material and processing technology suitable for the product according to the requirements and characteristics of the product.

The main steps of mold design include product analysis, mold structure design, mold parts design, material and heat treatment selection, process design, etc. The specific steps may vary according to the actual situation.

Commonly used mold design software includes AutoCAD, Pro/E, SolidWorks, UG, CATIA, etc. Different software has its own advantages and disadvantages, choose according to actual needs.

Matters that need attention in mold design include product characteristics and requirements, rationality of structure, material selection and heat treatment, etc. At the same time, it is also necessary to pay attention to the feasibility of the processing technology and the maintenance of the mold.

The main difficulty in mold design lies in how to design mold structures and materials that meet product requirements, while considering processing technology and cost control. At the same time, problems such as life and maintenance of the mold need to be solved.

Get Instant Quote

Request your free injection molding quote today and we will get back to you to establish communication.