Plastic electronic enclosures are electronic and electrical protective enclosures manufactured by injection molding. They have good physical properties, wear resistance, high temperature resistance, and strong insulation properties. Widely used in various electronic and electrical equipment.

Injection molding is an efficient and high-precision plastic processing method, which is very suitable for mass production of electronic and electrical housings. Because injection molding can realize the production of complex-shaped parts, and has the advantages of high efficiency, high precision, and high degree of automation.

At Mindwell, we implement fully customized process solutions for electronic plastic enclosure box material selection, mold design, processing technology, surface treatment and quality inspection. You only need to give us the drawings and we will customize the electronic enclosure you need.

Material selection

When selecting plastic raw materials for use in electronic and electrical enclosures, there are several key factors to consider to ensure the material can meet the requirements of the device. Commonly used plastic materials such as ABS, PC, PP, etc. have excellent properties in all aspects to ensure product performance and quality.

High temperature resistance

Electronic and electrical equipment usually generates a certain amount of heat, so the housing material must be able to withstand high temperature environments without deforming or melting. PC (polycarbonate) excels in this regard, as it has a high heat resistance and is able to withstand higher temperatures without losing stability.

Odporność na korozję

Electronic devices can be affected by a variety of environmental factors, such as chemicals or humidity. Therefore, the outer shell material must have good corrosion resistance to protect the internal circuitry from damage. In this regard, both PA (polyamide) and PBT (polybutylene terephthalate) excel because of their high chemical stability.

Mechanical strength

The enclosure must be able to protect the electronic components inside from physical impact and damage. ABS (acrylonitrile-butadiene-styrene copolymer) is a commonly used material that has excellent toughness and strength and can effectively withstand mechanical stress and impact.

In general, when selecting plastic raw materials for electronic and electrical housings, factors such as high temperature resistance, corrosion resistance, and mechanical strength can be comprehensively considered. Commonly used plastic materials such as ABS, PC, PA and PBT can meet these requirements and have the characteristics of good toughness, high strength, wear resistance and temperature resistance. They can provide reliable shell materials for electronic and electrical equipment. The specific materials are based on Electronic equipment needs to be customized for selection.

Electronic plastic housing design

The design of electronic plastic housing plays a very important role in electronic and electrical equipment. It is not only a simple shell that protects the external environment and internal components, but also relates to aesthetic appearance, ergonomics and user experience.

- Protect internal circuits and components: The most important thing is to ensure that the internal circuits and components are protected from damage by the external environment, such as dust, moisture, physical impact, etc. Electronic enclosures must provide adequate protection to ensure the reliability and durability of the equipment.

- Beautiful appearance: Appearance of the device An attractive design can increase the appeal of the product and attract more potential users. The look, color, and texture of the case can all become part of the brand identity and help build brand recognition.

- Ergonomics: The design of the enclosure must take into account the user’s usage habits and comfort. Ergonomic case design makes the device easier to hold, carry and operate. A good human-machine interface design can improve user satisfaction and convenience.

- User experience: The design of the device’s casing directly affects the user experience. Easily accessible buttons, interfaces, and displays, logical layout, and clear signage can all improve the user interaction experience. A good casing design can make users feel happy and increase their favorability of the product.

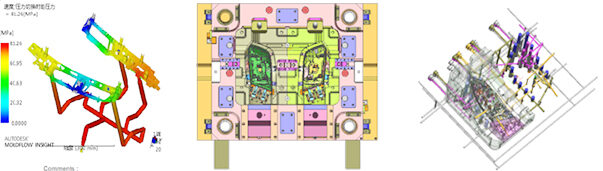

Housing design is very important to the success of electronic and electrical equipment. It is not only related to the protection and performance of the equipment, but also to user experience and market appeal. Therefore, in the product development process, full attention should be paid to the design of electronic housings, and mold design is the top priority for mass production applications of electronic housings.

Processing technology

The manufacturing process of electronic and electrical housings usually uses injection molding, which is a widely used and efficient method for manufacturing plastic parts.

- In injection molding, parameters such as material dissolution temperature, injection pressure, and injection speed need to be controlled to ensure the quality and accuracy of the shell.

- The injection molding process involves multiple steps, including injection molding, cooling and demoulding. During the injection molding process, the plastic material is heated and injected into the mold, and then the plastic solidifies during the cooling stage. This process requires strict control of each step and precise control of the progress.

- After the injection molding process, surface treatment is required. This can include spraying, electroplating, silk screen printing, laminating and other processes to improve the surface finish, flatness and durability of the shell. These surface treatment processes not only improve the appearance, but also increase the product’s corrosion resistance and wear resistance.

Generally speaking, the manufacturing process of electronic and electrical housings is a complex process involving multiple steps and parameter control. The final quality and performance of the enclosure also relies on precise control of the machining process and surface treatment. Through reasonable process and quality control, it is possible to ensure the production of high-quality electronic and electrical housings to meet the customized requirements for customized electronic plastic housing products.

Applications of electronic and electrical enclosures

Plastic shells are also widely used in electronic equipment, mainly in the following industries:

Mobile phones and tablets:

- TV and remote control

- Speakers and speakers

- Electronic game consoles and controllers

- household appliances

- sprzęt medyczny

- PCB panel

- industrial equipment

In addition, there are many electronic and electrical casings that use plastic injection molding processes. Plastic casings for electronic and electrical appliances play a key role in many electronic devices. They not only provide the function of protecting internal circuits and components, but also pass appearance, texture and design Provides users with a pleasant user experience.

Plastic casings for electronic products are one of the most commonly produced products by injection molding, because the use of plastic casings in electronic appliances is very common. We have more than ten years of production and processing experience in this area and can meet any of your customized needs. We Providing one-stop on-demand customized services in product design, mold design and mass production, surface treatment, assembly and packaging, you are welcome to contact us.