Product Assembly

MNW provides comprehensive assembly services, including manual and semi-automatic assembly lines, product online assembly testing and verification, etc. We are committed to achieving the goal of zero defect products, and adopt strict process management to ensure product quality.

- Complete assembly function

- strict process management

- ISO class 5 clean room

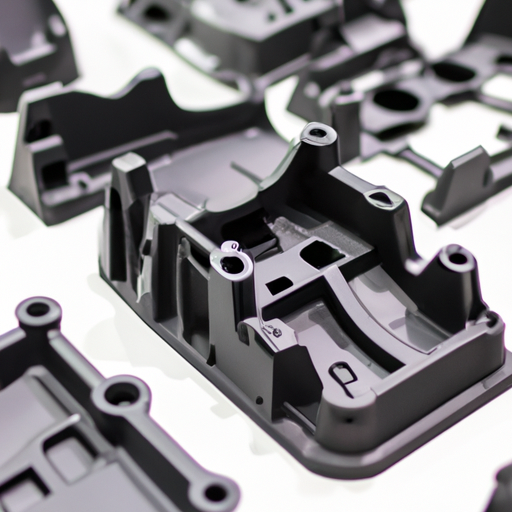

MindWell's Assembly Workshop

Our assembly services can be customized to ensure customer-specific product requirements and specifications are met.

After designing and producing injection molding and die-casting accessories at MindWell, you can assemble them into your electronic components, chips, wicks, etc. However, the cost of assembly after the overall transportation to your country is very high. At this time, MindWell provides the assembly function. You can send us your other accessories, or we will purchase them for you nearby and then assemble them for you. Deliver the finished product to your hands. The following is the assembly process:

- Parts processing and processing: After receiving the customer’s order, the die casting manufacturer will process and process the parts according to the requirements, so that they can be assembled smoothly.

- Parts assembly: Assemble the parts according to the design drawings and customer requirements to ensure that there will be no mistakes or failures during the assembly process.

- Inspection and testing: After the assembly is completed, the injection molding die casting manufacturer will also carry out strict inspection and testing to ensure that the assembled parts and the entire product can meet the corresponding standards and requirements.

- Packaging and delivery: After the assembly is completed, the injection molding die casting manufacturer will also package and mark the product, and deliver it to the place designated by the customer in time.

Get Started Now with Product Assembly According to Your Needs!

Assembly Services for Injection Die Castings

Assembly services for injection molded die castings can be applied in many industries. Including automotive, electronics, household, medical, industrial equipment, etc.

- The automotive industry can use injection die-casting parts to assemble various auto parts, such as rearview mirrors, main controls, etc.;

- The electronics industry can use injection molding die-casting parts to assemble various plastic shells, brackets, etc.;

- The home furnishing industry can use injection molding die-casting parts to assemble furniture, lamps, etc.;

- The medical industry can use injection molded die-casting parts to assemble various medical equipment;

About MindWell

The assembly function provided by MNW is very comprehensive, and manual and semi-automatic assembly lines can be carried out according to the needs of customers to ensure that our products can meet customer requirements. During the assembly of our products, in-line testing and verification are performed to ensure that each part will fit properly. We are committed to achieving the goal of zero defect products, so strict and enforced process management is carried out throughout the assembly process.

Our production workshop has ISO class 5 clean room capabilities, ensuring a clean and hygienic working environment, especially for products that need to be used in the medical and food industries. MNW has high standard requirements for each production process. We will continuously optimize and improve the production process, improve product quality and reduce costs to meet customers’ needs for high-quality products.

Get Instant Quote

Request your free injection molding quote today and we will get back to you to establish communication.