Product Design

Mindwell adopts strict procedures in the creation process of each design and development project. Most of our company serves European customers, so every link in production has reached European standards. In each design and development project we undertake, There are standard and strict product design processes.

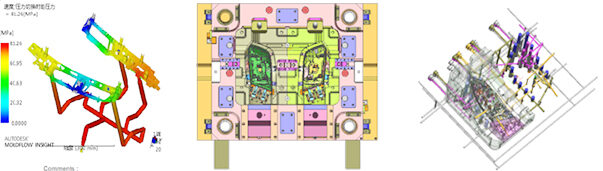

- Custom Die Casting, Injection Molded Products Projects

- Mold development and manufacturing

- Prototype->OTS->PPAP->SOP stage

Customized Service

Our Project development process

Our company has advanced technology and a professional team of engineers, our product design engineers have rich experience in die-casting product design and injection molding product design, and can design any injection molding, die-casting products you want.

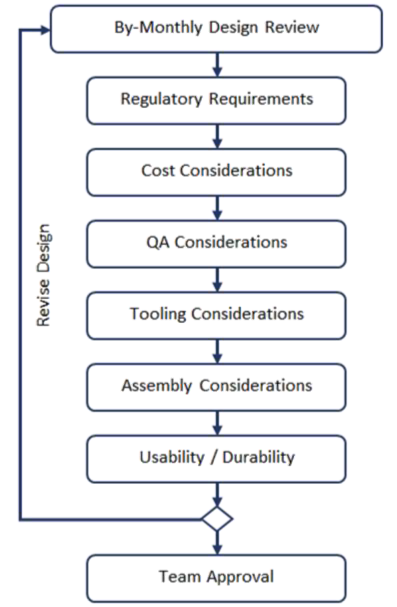

By-Monthly Design Review

Regulatory requirements, cost considerations, QA considerations, tooling considerations, assembly considerations, availability/durability, team approval, etc. for the product.

regulatory requirements

When conducting a design review, the regulatory requirements of the product need to be considered, including compliance with regulations and standards, as well as product quality and safety performance.

cost considerations

Costs need to be considered, including material and manufacturing costs, and to ensure that the quality of the product is as expected.

QA Considerations

In terms of QA considerations, design reviews need to examine the product’s quality management plan and ensure that the design meets the product’s performance and quality standards.

Tooling Considerations

It is necessary to consider the suitability of the production process and materials, as well as the repair and maintenance of the mold.

Assembly Considerations

When it comes to assembly considerations, there is a need to ensure that all parts and fixtures fit and work perfectly.

Usability / Durability

Consider product usability and durability, including aspects such as service life and repairability.

Team Approval

Design reviews also require team approval to ensure that all design options are fully evaluated and approved.

After completing the design review, it is necessary to expand and improve the product design, including the adoption of new technologies, compliance testing and acceptance, to ensure the integrity and optimization of the product design.

MINDWELL's Injection Molding Service Manufacturing Capabilities

When designing products, we have strict requirements on the structural design points of injection molded parts from the aspects of product wall thickness, draft angle, ribs, holes, pillars, buckles, interference connections, tolerances, and fillets. Of course, the structural design is also limited by the environment, conditions, and requirements, and it must be dealt with in specific situations.

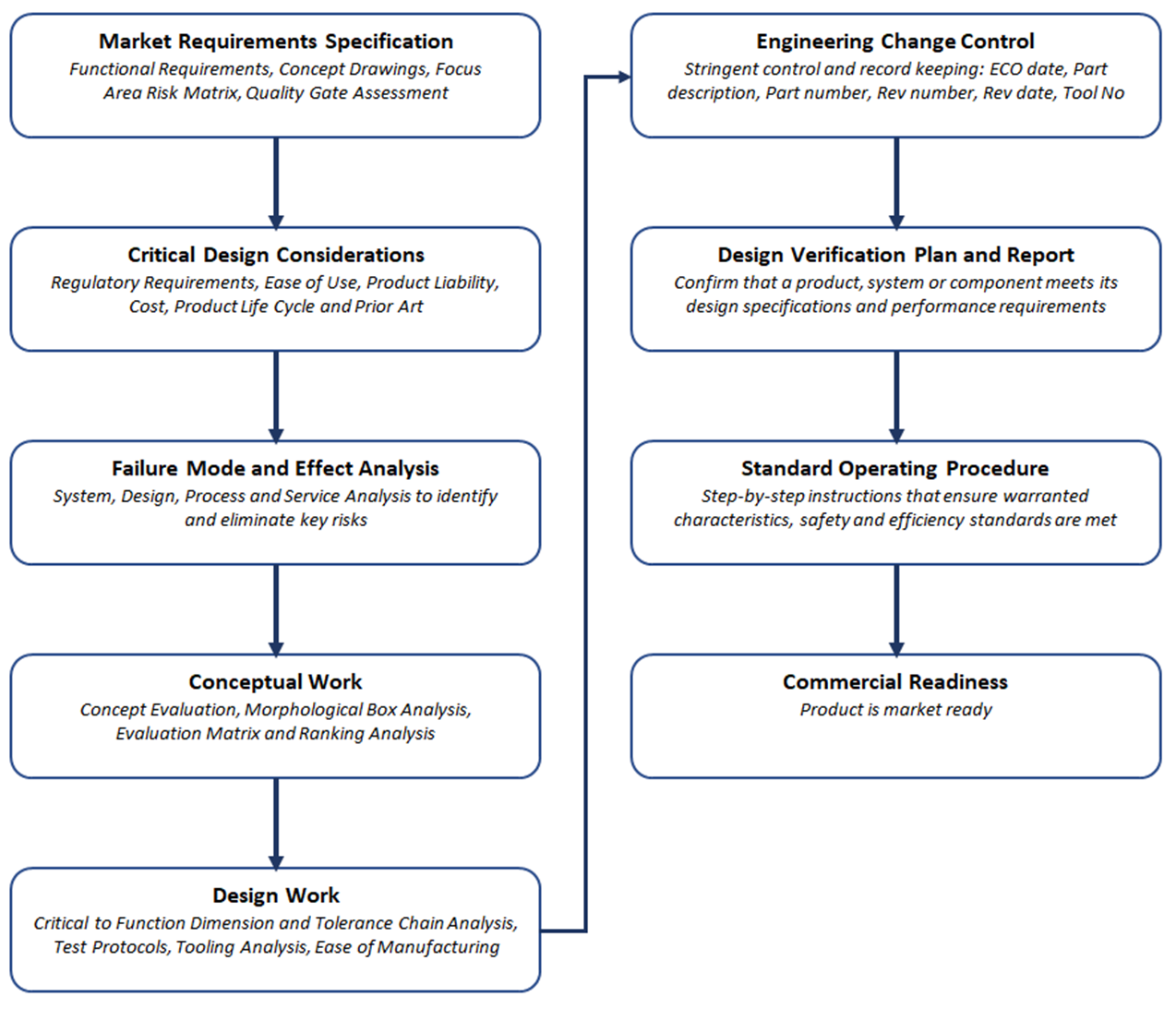

Commercial Readiness means:

- Quality Gate QG0 to QG5 are complete

- FMEA Documents are complete and known risks have

been eliminated or mitigated to the maximum extent - DVP&R Testing is complete

- Regulatory Certificates of Compliance are issued

- All 3D data is current

- All 2D data is current

- All critical to function dimensions are clear and current

- Engineering Change Orders are documented and

approved - Production standards are complete including process

parameters, approved dimensions, test methods, test quantities, test equipment, stated acceptable test results and failure actions - SOP validation and refinement are completed

- Functional requirements are met

- Quality targets are met

- Cost targets are achieved

Product designs must ensure warranted characteristics are met, human life is protected to the greatest

extent possible and the environment and resources

are preserved to the greatest extent possible.

Welcome to start designing your parts product

Why Choose MINDWELL For Product Design

We have always been focusing on the overall custom design solutions for hardware products, from product design to packaging and assembly, we hope that our customers can get high-quality products and can do it in one go.

If you choose Mindwell as the design solution provider for hardware products, you can get professional, innovative and high-quality design services, because Mindwell has the following advantages:

- Have rich experience in hardware product design and technical strength, and be able to provide high-quality design schemes and solutions.

- Pay attention to user experience and market demand, and be able to provide design solutions that meet market demand and user needs.

- Using modern design software and technology, able to provide customers with innovative and efficient solutions.