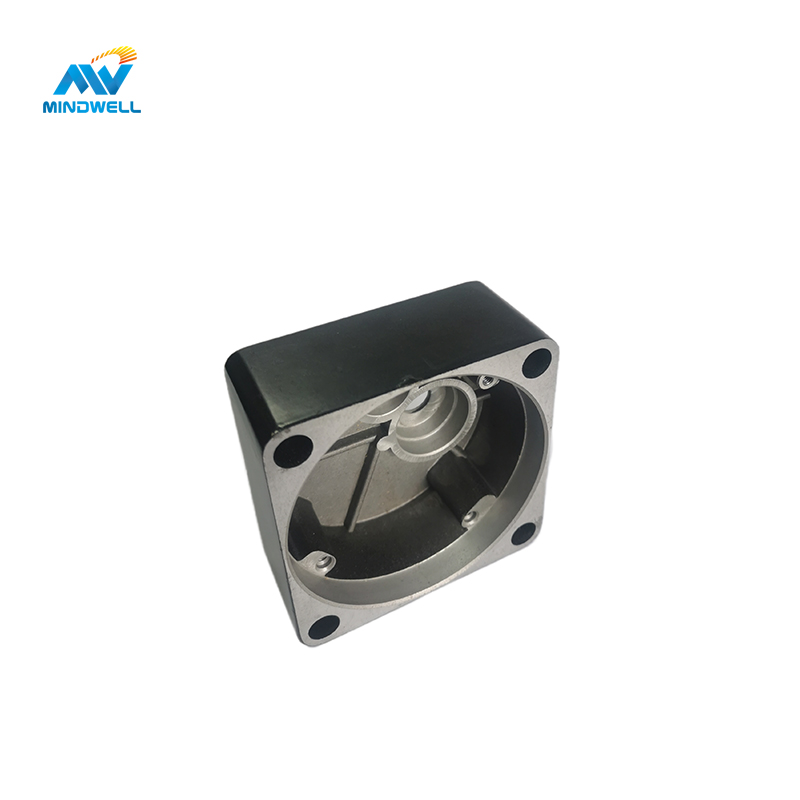

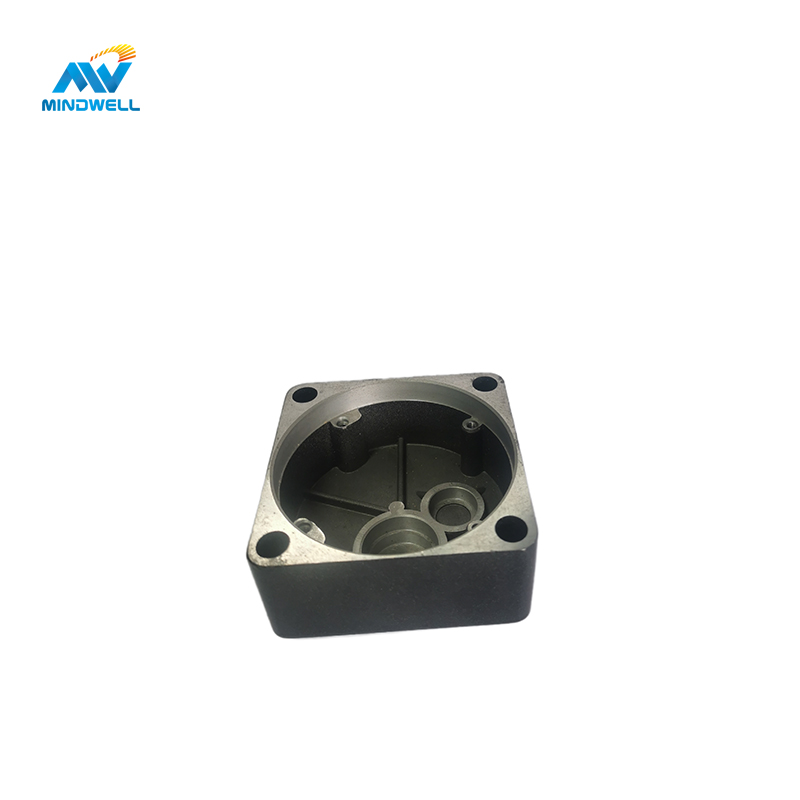

Do you want a dependable and long-lasting housing option for your goods? Our bespoke die cast aluminum housing is the only solution you need. Die cast aluminum is the ideal material for high-quality enclosures that can survive even the toughest conditions because of its remarkable strength and adaptability.

Why Choose Die Cast Aluminum Housing?

Because of its many advantages, die-cast aluminum is considered one of the finest materials for housing applications. For your unique housing requirements, die cast aluminum is a good option for the following reasons:

- Sturdiness and longevity: aluminum die cast is renowned for having a remarkable strength-to-weight ratio. It is perfect for situations where durability is important as it is lightweight yet highly durable. No matter how harsh the weather, wetness, or impact is on your items, our die cast aluminum casing will provide the required defense.

- Resistance to Corrosion: Corrosion is inhibited by the protective oxide layer that aluminum naturally develops. Die casting, which produces a consistent and solid surface, improves this innate corrosion resistance even further. Even under challenging conditions, the die-cast aluminum housing that we manufacture will not corrode.

- Flexibility in Design: Die-cast aluminum gives you the flexibility to construct unique housing solutions that precisely meet your product needs by allowing for detailed and complicated designs. We are able to create housings with accurate measurements, thin walls, and elaborate details thanks to our sophisticated die casting processes.

- The ability to conduct heat: Because aluminum is a superior heat conductor, the housing can effectively control internal temperature. This is particularly crucial for heat-generating goods since it aids in heat dissipation and guards against overheating. Your items will stay cool and function at their best temperatures with the aid of our die cast aluminum casing.

- Economical Resolution:Die cast aluminum is a more affordable material when it comes to specific housing requirements. Lower manufacturing costs may be achieved by using the die casting technique, which enables high-volume production with less material loss. Die cast aluminum housing’s lifespan and durability also lessen the need for frequent replacements, which lowers total expenses.

Customization Options

We at Mindwell are aware that each product is unique. We provide a plethora of customization choices for our die cast aluminum housing as a result.

- Completing Choices: To improve the look and shield the housing from the weather, choose from a range of surface treatments, including as painting, anodizing, and powder coating.

- Assembly and Machining: We may add extra features, such as threaded inserts, mounting holes, and bespoke cuts, to guarantee a flawless integration with your product thanks to our cutting-edge machining skills.

- Branding and Logo: For a polished and unified appearance, add your branding or logo to the housing using a variety of techniques, such as engraving, embossing, or custom labeling.

- Dimensions and Form: To ensure a flawless fit for your product, our die cast aluminum housing may be tailored to match your exact size and form needs.

Applications

Numerous sectors and uses may benefit from our bespoke die cast aluminum housing, including:

- Technology

- Automobile

- Aircraft

- Industrial apparatus

- medical equipment

- Communications

Our die cast aluminum enclosure will provide the required protection and usefulness whether you need it for electronic control panels, automotive parts, or medical equipment.

Die-cast aluminum housing’s surface treatment

Die-cast aluminum housing often requires surface treatment after manufacturing to enhance appearance, boost corrosion resistance, and satisfy application-specific requirements. The following are typical coatings for die-cast aluminum housings:

- Anodizing is a popular surface treatment technique that forms an oxide deposit on the aluminum surface to increase the shell’s hardness and resistance to corrosion. The housing may also be anodized to provide various colored surface layers.

- Painting/Coating: Enclosures may be painted to improve their appearance and offer further corrosion protection. It is possible to satisfy certain environmental standards by using the right coating materials and processes.

- Using an electrophoretic procedure, a coating may be uniformly applied to the housing’s surface using the electrophoretic painting technique. An even, thick coating that increases resistance to corrosion and scratches is offered by electrophoretic coating.

- Polishing: The case’s texture and surface quality are enhanced by polishing. Depending on the necessary level of surface smoothness, polishing may be done mechanically or chemically.

- Sandblasting is a technique that may produce a textured surface and make an object seem more distinctive by spraying sand particles into the shell’s surface using a high-pressure gas or mechanical methods.

- Powder Coating: This technique involves uniformly misting powder coating over the shell’s surface, then melting and solidifying it in an oven. An uniform, durable surface is produced via powder coating.

The particular application, aesthetic standards, environmental factors, and anticipated performance requirements all play a role in choosing the right surface treatment.

Заключение

Our die cast aluminum housing is a standout option for bespoke housing solutions due to its strength, durability, adaptability in design, and affordability. With our wealth of customization choices, you may design a housing that precisely fits the needs of your product. You may rely on [Your Company Name] to provide superior die cast aluminum housing that will surpass your anticipations.