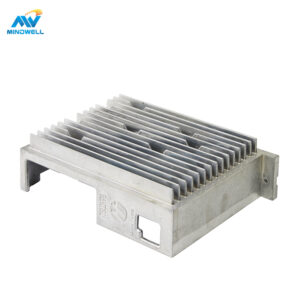

The electric motor housing die-casting custom product is a motor housing made by die-casting technology, which can be customized according to customer needs. With its exceptional accuracy, robustness, light weight, and attractive look, this bespoke motor housing can satisfy a wide range of client demands for both motor performance and aesthetics. Our die-cast custom motor housing product at mindwell is a premium item with excellent accuracy, strength, light weight, and attractive look. We provide thorough, personalized services to satisfy the unique requirements of various industries and clients. Selecting us will result in superb product quality and worry-free post-purchase assistance.

Electric motor housing eatures

- High precision: To guarantee that the motor housing size is precise and satisfies client specifications, sophisticated mold and die-casting technologies are used. This not only increases the motor’s performance but also lessens the difficulties of assembly and troubleshooting in the future.

- High strength: To guarantee that the electric motor housing has enough mechanical strength and stiffness and can endure a variety of hard working situations, choose premium metal materials, such as zinc alloy, aluminum alloy, etc. Furthermore, the impact resistance of the housing is considerably enhanced by the precision die-casting technique.

- Lightweight: The die-casting technique may provide a motor casing that is lighter and thinner than that of conventional casting processes, which lowers the motor’s total weight and facilitates handling and operation. This is particularly appropriate for situations when weight restrictions are necessary, such in new energy vehicles, aircraft, etc.

- Beautiful: The motor shell’s smooth, flat surface and high appearance quality may enhance the motor’s overall perception. Either a polished metal surface or a finely detailed texture may demonstrate the product’s complexity and high caliber.

- Effective production cycle: By using cutting-edge die-casting technology, the production cycle is significantly shortened, enabling prompt fulfillment of client demands.

- Good environmental performance: We take environmental protection seriously when producing. Before being released into the environment, all waste products and wastewater are processed.

Application range

The die-cast custom electric motor housing product is a bespoke housing intended for a variety of motors, primarily AC, DC, and servo motors. Die-casting is used in the production of this product, and housings with various dimensions and forms may be tailored to clients’ unique requirements in order to satisfy motor applications across many industries.

Applicable motor types:

- AC Motor: Motors of different sizes and powers may be used with this motor housing. Since AC motors are used extensively in the manufacture of automobiles, industrial automation, and other sectors, specialized housings may be made to fit the requirements of many application situations.

- DC motors are another popular sort of motor that are often used in new energy, industrial automation, and other industries. The capacity to adjust the motor housing to the various DC motors’ size and form requirements is ensured via customization.

- Servo Motors: In the fields of robotics and industrial automation, servo motors are crucial. The requirements of servo motors in high-precision and high-performance applications may be satisfied by altering the housing.

Application areas:

- Industrial Automation: To guarantee motor performance and stability, customized motor housings may be used in a range of industrial automation equipment.

- Electric cars, wind energy, solar energy, and other disciplines are among the new energy industries that use motor housings to suit the performance and operating environment needs of various motors.

- Automobile manufacturing: To increase overall performance and efficiency, bespoke motor housing components may be used in a variety of vehicle electric systems.

- Aerospace: To satisfy the needs of the motors on airplanes, satellites, and other aircraft, the aerospace industry also uses customized motor housings.

Custom features:

- Flexible specs: electric motor housing may be made to fit a variety of motor types with varying sizes and specifications based on the unique needs of the clients.

- Variety of Shapes: The housing’s shape may be altered to meet the requirements of the application, guaranteeing a perfect fit and functionality.

- Material selection: To guarantee the strength and corrosion resistance of the shell, suitable materials, such as aluminum alloy, magnesium alloy, etc., may be chosen based on the usage environment and needs.

Customized services

- Customized service: The main emphasis of your service is creating electric motor housing that is specifically tailored to the customer’s specifications and needs. This guarantees that the product completely satisfies the unique requirements of the consumer, boosting customer happiness and product appropriateness.

- Material Selection: The meticulous selection of materials for the motor housing is part of your service. This may be done in accordance with the application environment and specifications of the client, guaranteeing that the enclosure has the required strength, resistance to corrosion, and other performance attributes.

- Dimensional design: Depending on the various application situations, customers may have varied size needs for their motors. As part of your service, you design the housing’s dimensions to guarantee that it precisely fits the customer’s motor while also fulfilling space and performance criteria.

- Surface treatment: To increase longevity and aesthetics, the motor housing’s surface treatment is crucial. Surface treatment is part of your service to guarantee that the enclosure works and looks well in a range of conditions.

- Professional teamwork: Since you place a strong emphasis on working closely with clients, your team will collaborate and communicate with them in an efficient manner to guarantee that their demands are properly recognized and satisfied. This close cooperation makes it possible to guarantee that the specialized motor housings satisfy client needs.

- Customer satisfaction orientation: It is evident from your services that you are committed to fulfilling the requirements and expectations of your clients. By offering a comprehensive array of customized services, you pledge to guarantee that your clients are pleased with the caliber and functionality of their custom electric motor housing.

- Broad application: Your services have a broad range of uses in industrial automation, new energy, aerospace, automotive manufacture, and other industries since they are appropriate for different kinds of motors.

Assurance of Quality

Every product undergoes a rigorous quality check to guarantee that it satisfies client needs and design specifications. Simultaneously, we provide thorough after-sales support to swiftly address and resolve issues that come up while using the device. We consistently provide the best goods and services to our clients by upholding the quality first philosophy.

- stringent quality inspection procedure: Every customized product is subject to a stringent quality examination by our organization. This covers every step of the process, from raw material inspection to manufacturing process monitoring to final product inspection. We confirm that the product satisfies the strict quality standards and design specifications by going through this set of testing procedures.

- Adhere to design specifications: The purpose of quality control is to verify that the product satisfies both the particular needs of the client and the design standards. This increases the consistency and dependability of the product and helps prevent production flaws.

- consumer Satisfaction: Our business is dedicated to making sure that items can live up to consumer expectations via quality testing and specialized services. Prioritizing client pleasure fosters enduring connections and boosts consumer faith in your company.

- Exceptional after-sales support: delivering exceptional after-sales support is essential. In order to boost consumer trust in the product and provide them extra protection, our organization is dedicated to quickly resolving and managing issues that come up during product usage.

- The quality first philosophy: Our business constantly upholds the “quality first” idea. This dedication is evident in every facet of product production as well as in the company’s general culture and beliefs, which guarantees the development of a trustworthy, superior brand image in the marketplace.

- Best quality goods and services: Our business aims to differentiate itself in the fiercely competitive market by focusing on “best quality” goods and services. This is evident not just in the quality of the goods but also in the way that clients are treated and the post-purchase support provided.

- continual improvement: The idea of continual improvement is embodied by our company’s emphasis on the quality of our products and services. Your business may anticipate continuous improvements in the caliber of its goods and services if it consistently evaluates and enhances its procedures.