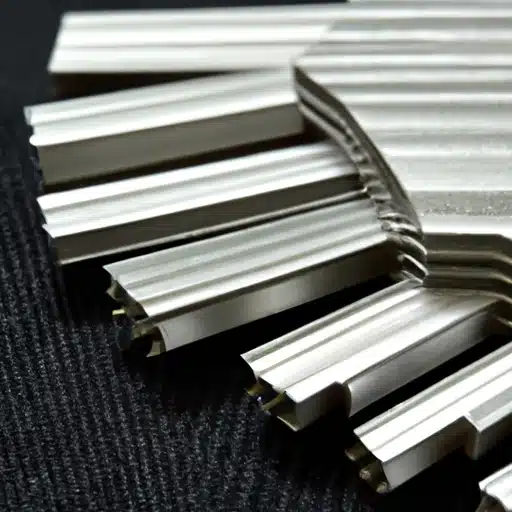

What is the process flow of aluminum alloy die castings?

Aluminum alloy die-casting process is an efficient and precise metal forming process for manufacturing aluminum alloy parts. By injecting high temperature and high pressure liquid metal into the mold, it is cooled rapidly and formed aluminum alloy parts with good mechanical properties and surface quality. The aluminum alloy die-casting process can be used to manufacture …

What is the process flow of aluminum alloy die castings? Read More »