Furniture Industry

Hardware accessories are widely used in the furniture industry, including injection molding parts, die casting parts, etc. In furniture production, injection molded parts and die-casting parts are important parts, and their quality is directly related to the service life and safety performance of the entire furniture.

- Injection molding, die casting, stamping parts and other one-stop services

- ISO 9001 certified factory

- good after-sales service

On-Demand Production

Our furniture parts processing technology

For common tables, chairs, bed frames, etc. in furniture, the connecting parts used are mostly die-casting parts. These connectors are usually made of plastic or aluminum alloy die-casting, have high strength and stability, can effectively support and connect various parts of the furniture, and are more wear-resistant and easy to process.

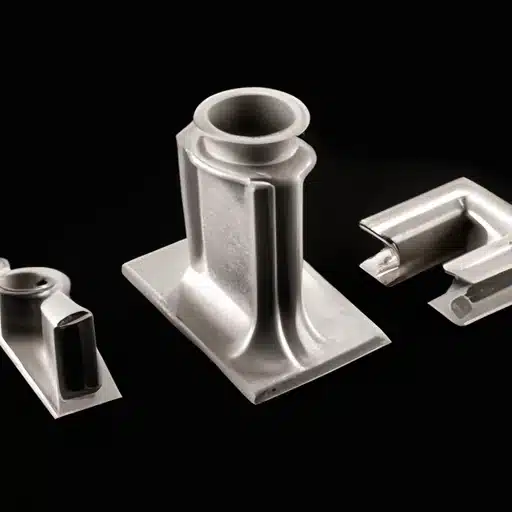

furniture die casting

In the furniture industry, die castings are usually used to manufacture furniture connectors, brackets, hinges, handles and other components. These parts usually need to bear a certain weight and pressure, and need to have high strength and stability.

injection molding furniture

injection molding furniture includes plastic feet of chairs or sofas, furniture brackets, connectors, components, etc.The injection molded parts of furniture have the characteristics of waterproof, moisture-proof and easy to clean.

Get Started Now with Custom Furniture parts According to Your Needs!

Application of Furniture parts

Die-casting parts are mainly used in building components and metal furniture. Die-casting parts have the characteristics of high strength and good stability. Injection molded parts are used for chair seats, sofa seats, etc. Injection molded parts are generally made of plexiglass, PVC, PP, PE and other materials, which are waterproof, moisture-proof, and easy to clean.

Die-casting furniture parts are usually made of aluminum and aluminum alloys for die-casting manufacturing, because aluminum alloys have high strength and stability. At this time, it will be made into a connector, and after connecting different furniture parts, it will play a stable role.

Furniture injection molded parts are widely used:

- The bottom plastic feet of a chair or sofa

- Handles on furniture surfaces such as drawers and doors

Furniture connectors, such as bolts, pins, threaded rods, etc. - Furniture supports, such as clothes hangers, shoe racks, bookshelves, etc.

- Furniture joints, such as door hinges, velvet cover plates, glass clips, etc.

- Furniture components such as chair backs, armrests, table legs, panels, etc.

- Furniture invisible accessories, such as hidden brackets, board connectors, corner brackets, etc.

- Furniture trims such as slats, doors, shades, conduits, etc.

- Furniture details, such as pulleys, plastic gaskets, screw caps, rubber pads, etc.

Frequently Asked Questions

Furniture parts are hardware parts that need to be used in furniture production, which can be injection molding parts, die casting parts, stamping parts, etc. Choose different materials according to the position and effect of the parts used. For example, die castings are generally used for connection and fixing, because die castings have high stability and good quality. Injection molded parts are usually used for heat insulation, electricity insulation, wear resistance, etc., and play the role of lightness and wear resistance.

Common injection molded parts in the furniture industry include chair and table bases, cushions, armrests, chair legs, drawer pulls, and more.

Common die castings in the furniture industry include door handles, handles, lock cylinders, bed frames, furniture legs, etc.

The manufacturing cost of injection molded parts and die casting parts is relatively low, the production speed is fast, the manufactured parts have good appearance quality, high precision, easy mass production, and are suitable for mass production.

Injection molded parts and die-casting parts have limited material choices. Generally, only plastic or metal materials can be selected. The manufactured parts are relatively fragile and are not suitable for high force or impact. Usually, they can only be used in light or medium load environments. At the same time, the production of injection molded parts and die-casting parts requires investment in certain equipment and human resources, and the cost is relatively high.

Get Instant Quote

Request your free injection molding quote today and we will get back to you to establish communication.