Polyethylene Injection Molding

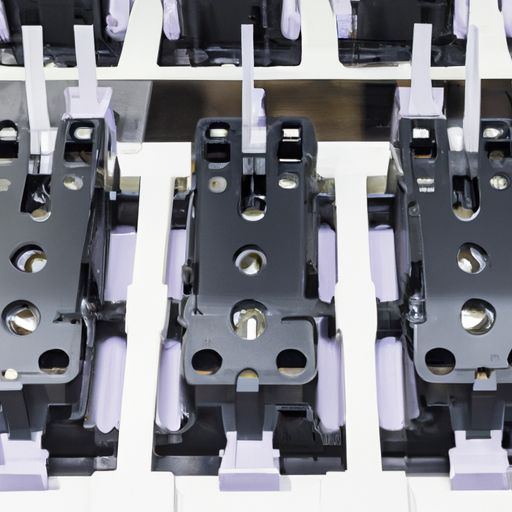

In the injection molding process, the PE particles need to be heated and melted first, then the melted PE is injected into the mold, and the desired product is obtained after cooling and molding. Polyethylene injection molding process is simple, low cost, high efficiency, and can be widely used in packaging, construction, electronics, medical, home and other fields.

Polyethylene Injection Molding Process

Polyethylene injection molding is divided into high-density polyethylene (HDPE) and low-density polyethylene (LDPE). The main difference between them is the density. We also choose polyethylene with different densities according to your materials. what is the difference

HDPE injection molding

HDPE has a higher density than LDPE, typically between 0.95 g/cm³ and 0.96 g/cm³. Since the molecular chain of HDPE is shorter than that of LDPE, its crystal molecular locking is stronger, HDPE is harder and more durable than LDPE, and its physical properties are superior, such as high strength, high hardness and higher melting point. Therefore, HDPE is usually used to manufacture products with high strength, high durability and high quality requirements.

LDPE injection molding

LDPE has a lower density, usually between 0.91 g/cm³ and 0.925 g/cm³. LDPE is very soft and easier to shape and process than HDPE. Due to the long molecular chain of LDPE, the inter-molecular gap is large, and it has high flexibility, smooth surface, heat insulation and sound insulation. Therefore, LDPE is usually used to manufacture products with low strength, low durability and low quality requirements.

Get Started Now with Custom Polyethylene Injection Molding Services According to Your Needs!

Application of Polyethylene Injection Molding

LDPE is usually used to make plastic bags, garbage bags, plastic film and other packaging purposes, while HDPE is often used to make water pipes, chemical barrels, food containers, etc. Both LDPE and HDPE are excellent plastic materials, and different materials can be selected according to different application scenarios.

Related Injection Molding Materials

ABS Injection Molding

pvc Injection Molding

Polycarbonate Injection Molding

PPE Injection Molding