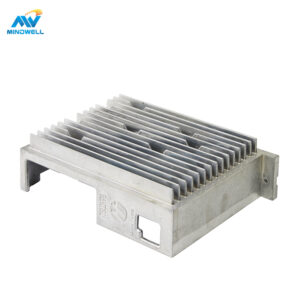

The purpose of the aluminum heatsink enclosure is to disperse heat from electrical components. Its primary job is to efficiently disperse the heat produced by electrical components so that the device operates at peak efficiency and has a long service life. This enclosure can handle high temperatures and high pressure situations because it is constructed of high-quality aluminum alloy material, which also has outstanding mechanical strength and thermal conductivity.

One of the most noteworthy aspects of the aluminum heatsink enclosure is how well it dissipates heat. Due to the high thermal conductivity of aluminum alloy, heat produced by electronic components may be rapidly transferred to the housing’s surface and then dispersed by forced or natural convection into the surrounding area. By preventing electronic components from overheating, which can cause damage, performance issues, or even safety concerns, this efficient heat dissipation device saves them.

The aluminum heatsink enclosure also boasts outstanding aesthetics and resistance to corrosion. It can withstand environmental degradation from moisture, dust, chemicals, and other elements while maintaining steady performance over an extended period of time. In addition, aluminum alloy materials can be subjected to several surface treatments, including powder coating or anodizing, to improve their appearance and ability to withstand corrosion.

The structural design flexibility of aluminum heatsink housings is another noteworthy characteristic. To get the optimal heat dissipation effect, it may be tailored and developed in accordance with the needs of certain electronic equipment and applications. This includes optimizing the form, size, placement of the heat dissipation hole, and other factors. Because of its versatility, aluminum heatsink housings are frequently used in a wide range of electronic devices, including power supply, computers, and communication equipment.

Main features

The main characteristics of an aluminum heatsink enclosure can be summarized as follows:

A. Advanced Thermal Management

Aluminum enclosures for heat sinks are renowned for their superior thermal management capabilities. It can swiftly and effectively disperse the heat produced by electrical equipment because of its great thermal conductivity. Our housings enhance the life and dependability of electronic components by maintaining stable performance in high-temperature conditions through optimal design and material choices.

B. Sturdy structure

The superior-grade aluminum alloy used to make the aluminum heatsink enclosure offers outstanding mechanical strength and resistance to corrosion. In addition to aiding in the optimization of heat dissipation, the housing structure is developed with the installation and protection of electrical components in mind. We are able to offer a strong, dependable housing with superior heat dissipation capabilities by taking these steps.

C. Precision Engineering

When producing aluminum heatsink enclosures, we employ precise engineering and state-of-the-art production techniques. This guarantees maximum thermal efficiency while enabling the enclosure to conform precisely with the electrical components. Our ability to precisely manage dimensions and apply careful surface treatment allows us to offer housing designs that satisfy a wide range of application requirements.

Technical specifications

The technical specifications of the aluminum heatsink enclosure are as follows:

A. Dimensions and Specifications

We provide an assortment of aluminum heatsink enclosure in varying sizes and specifications to accommodate different electrical equipment and cooling requirements. To suit the unique demands of each of our clients, we also provide custom sizing services. Please take notice that the size, power, and cooling requirements of the electronic item should be taken into consideration while choosing a size.

B. Surface treatment options

To enhance the aesthetics and durability of aluminum heatsink enclosure, we offer the following surface treatment options:

- Anodizing: Anodizing gives the case a durable, stain-resistant surface and gives it a range of color possibilities. Additionally, this treatment improves the housing’s insulation and resistance to corrosion.

- Powder Coating: For extra visual appeal, powder coating gives the shell a range of color and texture effects. In addition, the coating adds another degree of defense, enhancing the housing’s resilience to corrosion and overall longevity.

- Chemical conversion coating: To further improve the shell’s resistance to corrosion and wear, a transparent protective film can be applied using a chemical conversion coating treatment. Applications where maintaining the aluminum alloy’s original look is necessary can benefit from this treatment.

C. Installation flexibility

We provide an array of mounting choices with our aluminum heatsink enclosure to accommodate the various installation requirements of electronic systems:

- Standard mounting hole positions: To make it easier for customers to integrate into a variety of electrical systems, the housing design considers standard mounting hole locations. To meet the demands of various installation scenarios, we provide an assortment of hole patterns and spacing choices.

- Custom mounting brackets: We offer custom mounting bracket services to clients with unique installation requirements. Customers can supply the mounting bracket’s design specifications based on the demands of the real application, and we will produce and install it in accordance with those specifications.

- Compatibility and Precautions: Please make sure that the electronics and the aluminum heatsink enclosure are compatible before beginning installation. To guarantee correct installation and usage, please adhere to the installation instructions found in the product handbook.

Our aluminum heatsink enclosure can satisfy the requirements of different electrical devices and applications while offering the highest cooling performance and aesthetics, according to the aforementioned technical parameters. Please get in touch with us if you have any questions or unique requirements.

Industry application

Aluminum radiator shells are widely used in many industries. The following are the applications in several of them:

A. Electronics and IT systems

The cooling requirements of electronics, IT systems, and other heat-sensitive applications are satisfied by aluminum heat sink housings. In certain regions, system malfunction, damage, or deterioration might result from overheating and electrical component failure. Aluminum heat sink housings ensure that these devices work within a consistent temperature range by efficiently dispersing the heat produced by them, which increases system stability and dependability.

B. LED lighting system

Temperature has an impact on LED lighting systems’ lifetime, brightness, and efficiency. Aluminum heat sink housings are essential for effective cooling of LED components in LED lighting systems. We are able to retain maximum performance and prolong the life of the LEDs while optimizing heat dissipation through carefully planned housing structure and material selection.

C. Power electronics.

Although they are essential for power supply, amplifiers, and other equipment, power electronic devices also produce a lot of heat. In these locations, aluminum heat sink housings are crucial because they efficiently control thermal loads and guarantee that power electronics equipment run within a consistent temperature range. The stability and dependability of these devices are guaranteed by our aluminum radiator housings, which feature optimum structural design and effective thermal management.

Aluminum heat sink enclosures fulfill the specialized cooling demands of many equipment types, including power electronics, LED lighting systems, electronics and IT systems, and guarantee equipment performance and dependability. Please don’t hesitate to get in touch with us if you have any queries or requirements about these applications.