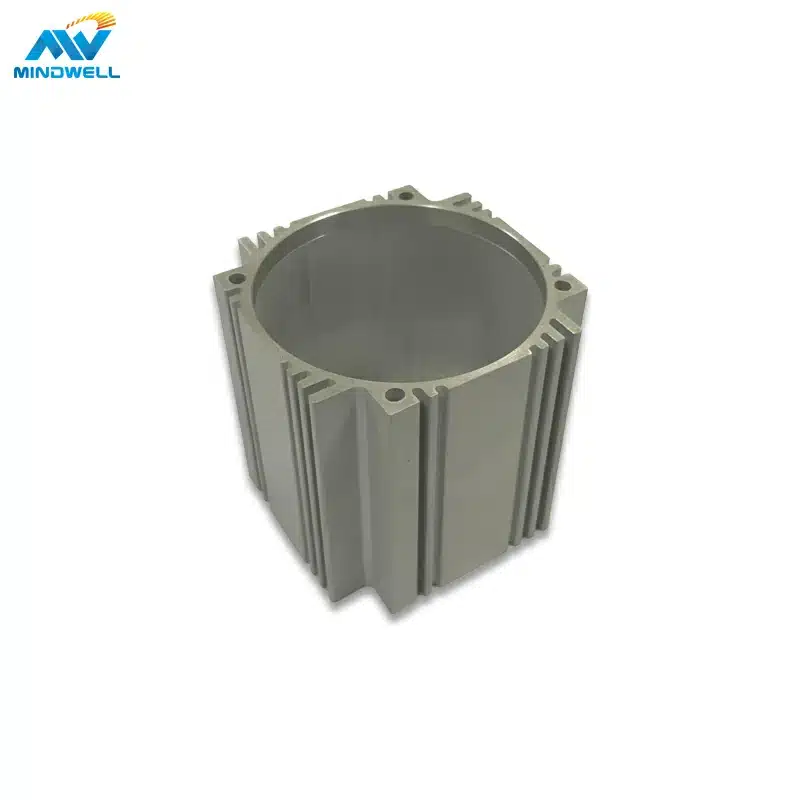

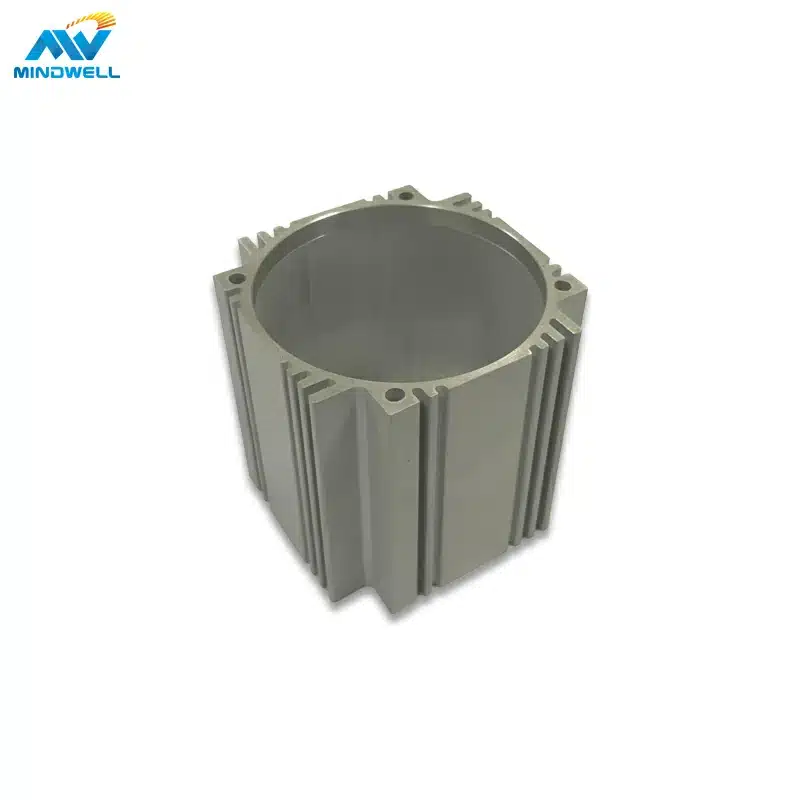

The motor casing is an important part for encapsulating and protecting the internal parts of the motor. It is mainly made of aluminum alloy and made by die-casting process. Aluminum alloy material has the advantages of light weight, high strength, good heat dissipation, high tensile strength, etc., which is very suitable for the requirements of the motor shell. Die casting is also a cost-effective process used to produce high-quality motor housings with complex designs and precise dimensions. Mindwell can customize the die-casting of the motor housing you need, and provide you with a favorable price and high-quality housing.

Design of die-casting motor housing

The die-casting design of the motor housing is crucial to the performance, appearance and reliability of the motor. Our engineers will also give you professional advice after receiving your design drawings. A good motor housing should be considered from the following points :

- Structural design: The structure of the motor housing should be designed taking into account the loads and pressures it will withstand. The structure should be strong enough to protect the motor’s internal components and maintain stability. At the same time, ensure that the design of the enclosure allows for the assembly and maintenance of internal components.

- Heat dissipation design: The design of the motor casing should take into account the heat dissipation requirements. Through the proper heat dissipation structure and heat dissipation channels, the motor can effectively dissipate the generated heat and keep the motor running within a safe temperature range.

- Sealing design: The motor casing needs to have a good seal to prevent external dust and moisture from entering the interior and protect the internal parts of the motor from damage.

- Aesthetic Design: The appearance of the motor housing is also an important consideration in the design. Through reasonable shape, edge treatment and surface treatment, such as spraying, the aesthetics of the shell can be increased, so that it can match the application scene and the overall design of the product.

- Manufacturability: Die casting parts should be designed taking into account the feasibility and efficiency of manufacture. Avoid overly complex shapes to reduce cost and production time while ensuring that the design fits the die casting process.

- Splicing and Assembly: If the motor housing is made up of multiple parts, design to ensure that these parts can be spliced and assembled accurately to form a complete housing structure.

- Production Costs: When designing a motor housing, manufacturing costs should be considered. Reasonable design can reduce material loss and processing difficulty, thus reducing production cost.

- Reliability and safety: Finally, the design should ensure that the motor casing has sufficient reliability and safety, can run stably for a long time under various working conditions, and protect the safety of the internal components of the motor and users.

The above things need to be considered when we design the motor shell. Reasonable design can improve the performance, durability and reliability of the motor, and provide a good guarantee for the application of the motor. Therefore, in MINDWELL, during the process of designing and communicating with customers, we are in close contact with customers to ensure that the final die-casting design meets all requirements, so that the function of the motor shell can be maximized.

Material

The first choice of die casting material for motor housing is aluminum, followed by magnesium. Aluminum and magnesium alloys are widely used because of their outstanding properties. Overall, however, aluminum is the most cost-effective and an ideal material choice for motor housings. The main reasons for choosing aluminum alloy are as follows:

- Lightweight and strong: Aluminum alloy has a lower density than other materials, making the motor shell lighter than other materials and contributing to the overall weight of the motor. Although the aluminum alloy is light, it is quite strong, giving adequate structural support and stability for the motor.

- great thermal conductivity: Aluminum alloy has great thermal conductivity, allowing it to swiftly transmit heat generated inside the motor and effectively disperse heat. This is crucial for the motor’s long-term operation and high-load activity, since it keeps the motor running within a safe temperature range.

- Processability: Aluminum alloy is simple to process and shape, making it ideal for die-casting complicated motor housing designs. Die casting technique allows for economical mass manufacturing as well as the creation of parts with great accuracy and consistency.

- Corrosion resistance: The surface of the aluminum alloy can be oxidized to boost corrosion resistance, allowing the motor casing to last longer in damp and severe situations.

- Recyclability: Aluminum alloy is a recyclable material that fulfills contemporary environmental awareness standards. When the motor’s service life is up, the waste aluminum alloy casing may be recycled and repurposed to lessen the environmental effect.

- Highly customizable: The aluminum alloy shell may be tailored to the demands of various motors in order to satisfy the unique requirements of various motor types and applications. Custom design can improve motor performance and efficiency by optimizing the structure and function of the motor housing.

- Advantage in total cost: When compared to other materials, the total cost of aluminum alloy motor housing is generally cheaper due to its light weight, high strength, superior thermal conductivity, and manufacturing efficiency.

Die casting motor housings has a number of advantages, including low cost, great production efficiency, and the ability to build complicated designs with strict tolerances. This method creates a consistent and dependable motor housing that protects and supports the internal motor components. It is the primary way of producing motor housings for a wide range of applications, including vehicle, appliance, and industrial equipment motors.

Why choose Mindwell as a custom motor housing die casting manufacturer

Mindwell is a professional motor housing die-casting manufacturer with more than ten years of experience. We are committed to providing high-quality, innovative and reliable die-casting housing solutions to customers around the world. The following are our main advantages:

- Mindwell’s team consists of engineers and technical experts with many years of experience and expertise in the die casting industry

- Equipped with advanced die casting equipment and technologies

- The material selection ensures maximum utilization of the material’s performance and efficiency.

- Focus on providing customized solutions for every project

- Strictly follow the ISO quality management system, and conduct strict quality control and testing in every link from raw material procurement to production process

- Provide customers with timely delivery with high-efficiency production and flexible production capabilities

- Pay attention to environmental protection