In modern manufacturing, appearance quality is one of the important indicators of a product. For an aluminum alloy die-casting factory, controlling product surface defects is a very critical link. Next, Mindwell aluminum alloy die-casting will be used as an example to introduce in detail how aluminum alloy die-casting factories control surface defects of aluminum alloy die-casting parts through process optimization and strict inspection.

Mold design and manufacturing

When we design and manufacture molds, we can ensure that the surface is flat, smooth, and free of scratches, dents or other defects. Proper mold design can reduce turbulence during the injection of gas and metal liquids, helping to reduce the occurrence of surface defects.

- Flat and smooth surface

- aerodynamic design

- Cooling system design

- Mold material selection

- Mold care and maintenance

Through the above precautions in mold design and manufacturing, the occurrence of surface defects in aluminum alloy die castings can be effectively reduced, and the quality and appearance of the product can be improved. The quality and design of the mold are one of the most influential factors in the aluminum alloy die-casting process, so full attention should be given to it in production.

Control the pouring temperature

At Mindwell, our technicians will reasonably control the pouring temperature of aluminum alloy to avoid too high or too low temperature. Pouring temperatures that are too high may result in oxidation of the metal, while temperatures that are too low may cause incomplete solidification. Stability of temperature control is crucial for surface quality.

Use appropriate release agent

Release agents can help aluminum alloy die-casting parts to escape from the mold smoothly and reduce strain and bubble formation. Make sure to choose a release agent that is suitable for the aluminum alloy material and process, and apply it evenly on the mold surface.

Control cooling rate

Proper cooling rate can help the aluminum alloy solidify uniformly and reduce the occurrence of surface defects. The cooling rate is controlled by adjusting the cooling system to ensure even cooling of the metal during solidification.

Eliminate gas and pores

Reasonable exhaust design can reduce the chance of gas being trapped inside the casting. Make sure there are adequate vents in the mold cavity and consider using a vacuum or gas channels to vent gases. Expand the content of this paragraph

material selection

Mindwell aluminum alloy die-casting factory attaches great importance to the selection of raw materials during the production process. The appearance quality of aluminum alloy die-casting parts is affected by the quality of aluminum alloy ingots. Therefore, Mindwell aluminum alloy die-casting factory will strictly control the purchase of aluminum alloy raw materials and select high-quality aluminum alloy ingots as raw materials for production. This can effectively reduce the impact on the surface quality of the product due to other impurities contained in the raw materials, and reduce the occurrence of surface defects.

Optimize process flow

Optimizing the process flow is also an important way to control surface defects. Mindwell Aluminum Alloy Die Casting Factory will optimize the molding process for different types of aluminum alloys and product designs. By controlling parameters such as melting temperature, injection speed, pressure, and mold temperature, we ensure that the aluminum alloy solution can be evenly distributed during the flow and cooling processes and avoid the generation of gas or inclusions. In addition, during the processing of aluminum alloy die-casting parts, precise control of the processing equipment is also key. Mindwell Technology uses advanced CNC machinery, that can accurately control various process parameters through computer programs. This ensures that the product surface can obtain uniform and stable pressure and avoid surface defects.

QC

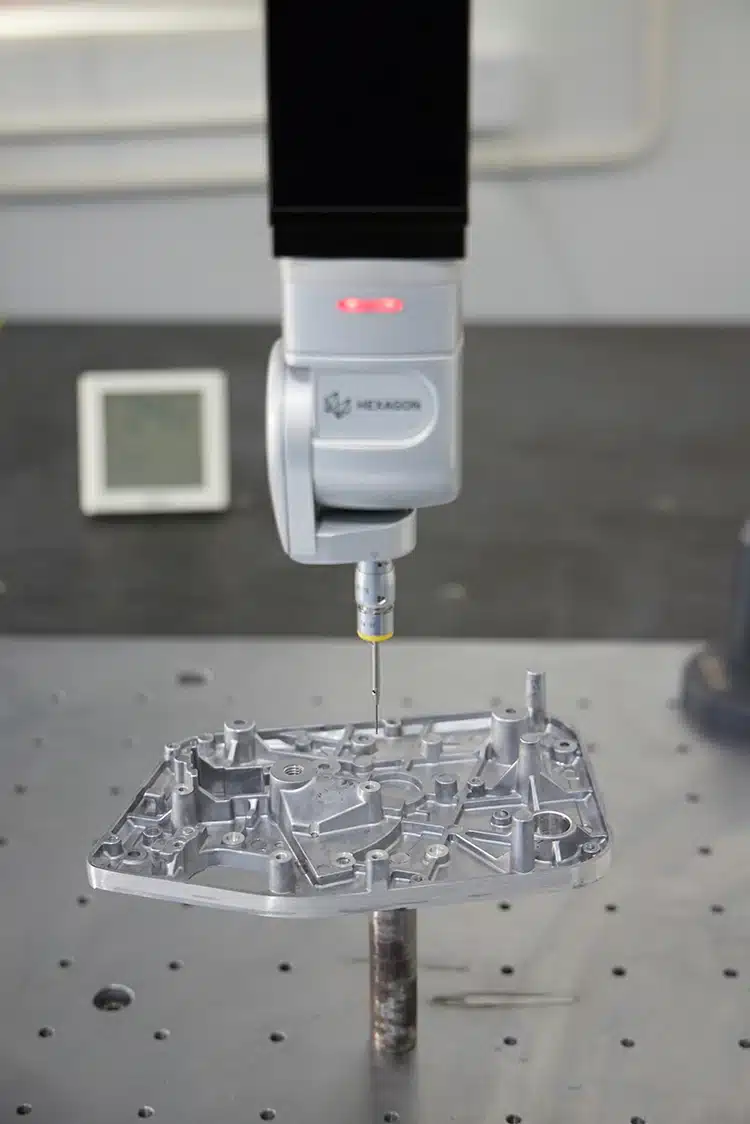

Strict quality inspection and control are also important parts of controlling surface defects. Mindwell Aluminum Alloy Die Casting Factory has established a complete quality control system and uses various testing equipment and means to conduct comprehensive inspections. For example, high-resolution microscopes are used to observe the fine structure of the product surface, and X-ray detectors and ultrasonic flaw detectors are used to detect internal defects. Through these inspection methods, factors that may cause surface defects can be discovered and eliminated in a timely manner to ensure that the product’s appearance quality reaches its best state.

professional skill

Mindwell Aluminum Alloy Die Casting Factory also pays special attention to employee training and skill improvement. Operating skills and experience during machining are critical to controlling surface defects. Mindwell Aluminum Alloy Die Casting Factory has trained a group of professional operators and continuously provides skills training and knowledge updates so that they are familiar with product characteristics, understand the processing technology, and can quickly and accurately deal with various surface defects.

Summarize

Mindwell aluminum alloy die-casting factory controls surface defects of products through optimized process flow, strict quality inspection and control, advanced processing equipment and employee training. These measures can effectively reduce the incidence of surface defects and improve the appearance quality of the product. Mindwell has more than ten years of experience in the field of aluminum alloy die-casting. We have strict control measures for the technical strength and quality assurance of the surface treatment of aluminum alloy die-casting parts to ensure that the selected products have good appearance quality.