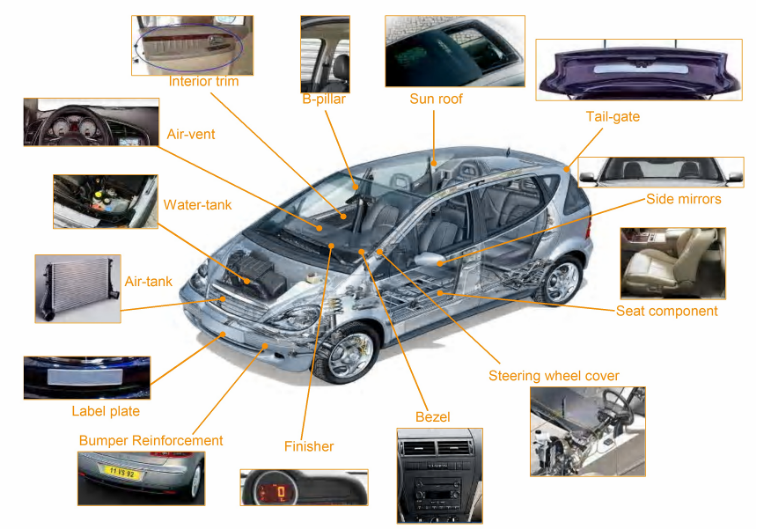

Injection molding process is very common in the automotive industry. Automotive plastic injection molding can be applied to various parts of the car, such as the air outlet of the air conditioner, main control, interior, internal parts and so on.

MindWell can provide automotive injection parts that meet your specific requirements. We can use various plastic materials, such as ABS materials, to produce high-quality automotive parts.

Custom Automotive Injection Molded Parts

We can provide custom injection molding services, our team of expert technicians and engineers will work with you, our technicians and engineers expertise in design, engineering and tool making to ensure that our products can meet your specific needs, designed The right part and create a product that meets your expectations.

Our company is also equipped with advanced machinery and uses the latest injection molding technology to ensure the production of durable, precise and long-lasting automotive injection molded parts for you.

Additionally, we know that time is of the essence and we strive to provide a fast turnaround time on all projects. We’ll connect quickly and get you a quote quickly, while still producing high-quality parts that meet your exact requirements.

Parameter

- Model material: NAK80, S136H, 718H, 738, P20 etc

- Drawing format: CAD, Proe, Solidwork, STP, IGS, PDF, AI etc.

- Plastic Raw Material: PP, PA6, PLA, as, ABS, PE, PC, POM, PVC, Pet, PS, TPE/TPR

- Certification: ISO9001, ISO14001, IATF16949

The use of injection molding in the automotive industry and retrofitting

- The use of injection molded parts in automobiles can not only improve the precision and stability of automobiles, but also reduce the cost of automobile manufacturing, and most importantly, it can better protect the environment. Therefore, injection molded parts have become an indispensable production method in the automobile production process. In the future, the application of injection molding technology in the field of automobile manufacturing will still have broad prospects for development and wide application.

- In the molding process of injection molded parts, precise molds and high-quality plastics can be combined to make the final molded parts more stable in quality and more accurate in size.

- Injection molded parts can greatly reduce the cost of automobile manufacturing. Compared with other production methods, the production cost of injection molded parts is lower, and it is efficient and fast.

- Mass production can be realized by using the injection molding process, which greatly reduces the production cost and improves the production efficiency of the automobile.

- Using injection molded parts can make car manufacturing more environmentally friendly. The injection molding process not only has an efficient production method, but also can recycle raw materials, reducing environmental pollution.