“Mindwell Casting” is a professional aluminum die-casting manufacturer with 10 years of experience. We offer high quality products at competitive prices.

Are you looking for high-quality aluminum die-cast products? Don’t hesitate any longer! In this blog, we’ll take a closer look at the world of top-notch die-cast products from China’s leading manufacturers. Imagine having durable, reliable and precision-engineered components that can take your projects to new heights. Whether you are in the automotive, aerospace, or electronics industry, these die-cast products are engineered to meet the most stringent standards.

Now, let’s talk about what you can find on this blog:

- Discussion of the advantages of aluminum die-casting

From its excellent strength-to-weight ratio to its corrosion resistance. - Showcasing 10 extraordinary die-cast products that will spark your imagination.

- Gain in-depth insights into manufacturing processes and highlight the cutting-edge technologies used by China’s leading manufacturers.

- Real-life examples of how these products enhance a variety of industries, demonstrating their versatility and reliability.

- An overview of the quality control measures the manufacturer implements to ensure consistent excellence.

Aluminum die castings offer excellent strength-to-weight ratio and corrosion resistance, making them ideal for use in a variety of industries. Mindwell Casting showcases 10 superior die-cast products that meet the most stringent standards. The manufacturing process uses cutting-edge technology and advanced equipment to ensure accuracy and quality. Real-life examples demonstrate the versatility and reliability of these die-cast products in enhancing various industries.

Introduction

Welcome to our comprehensive guide to high-quality aluminum die-casting products from China’s leading manufacturers. In this section, we provide a brief overview of the company and its manufacturing capabilities, emphasizing its commitment to providing best-in-class aluminum die castings to a variety of industries.

1.1 About Us

Our company was established in China and specializes in the production of high-quality aluminum die-cast products. With years of experience and a strong reputation in the market, we strive to be a trusted name for our customers’ superior casting solutions.

1.2 State-of-the-art Manufacturing Facility

Our manufacturing facility is a state-of-the-art production facility equipped with state-of-the-art equipment, including cutting-edge aluminum die-casting machines. These machines combined with our skilled workforce enable us to produce complex and precise aluminum castings to the highest quality standards.

1.3 Rich industry expertise

At our company, we serve a broad range of industries, including automotive, aerospace, electronics, medical, and more. Our experienced team works closely with clients to understand their specific requirements and create custom solutions that meet their needs.

1.4 Commitment to Product Quality

The primary reason for our success as a top manufacturer is our unwavering commitment to delivering high-quality products. All of our aluminum die castings undergo a rigorous inspection and testing process to ensure they meet precise dimensions, have a good surface finish, and comply with strict quality standards.

1.5 Comprehensive product scope

As a leading aluminum die casting manufacturer, we offer a wide range of products, including custom die cast parts for a variety of applications. Whether you need small batches or large-scale production, we have the capabilities to meet your needs.

1.6 Pay attention to customer satisfaction

Total customer satisfaction is core to our business operations. We believe in building long-term relationships by providing superior products, excellent customer service and timely delivery. Our commitment to customer satisfaction differentiates us from the competition.

1.7 Continual improvement and innovation

In order to maintain our leading position in the industry, we continuously invest in research and development and explore new die-casting technologies and processes. This allows us to provide cutting-edge solutions and stay at the forefront of industry trends.

Key Takeaway: Introduction provides an overview of China’s leading manufacturer of high-quality aluminum die-cast products. The company is known for its state-of-the-art manufacturing facilities, deep industry expertise, commitment to product quality, comprehensive product offerings, focus on customer satisfaction and continuous improvement and

What is aluminum die casting?

Aluminum die casting is a widely used manufacturing process in which molten aluminum is forced under high pressure into a mold cavity. The process enables the production of complex and precise metal parts with thin walls and excellent surface finishes. Let’s discuss the key aspects of aluminum die castings:

- Process:

There are several steps involved in aluminum die casting:

Preparation: The production facility prepares the die-casting machine, ensuring it is clean and well-maintained. Suitable molds and dies are also prepared.

Melting: The aluminum alloy is melted in a furnace to reach the desired temperature.

Injection: Molten aluminum is injected into the mold cavity at high pressure and speed to fill the mold’s complex shapes and features.

Cooling: The aluminum solidifies quickly inside the mold, forming the shape of the cavity.

Ejection: Removing a casting from a mold in preparation for further processing or post-processing.

- Advantages of aluminum die castings:

Aluminum die castings offer numerous benefits, making them a popular choice across a variety of industries:

Lightweight: Aluminum is lightweight and durable, making it ideal for applications where weight reduction is critical, such as the automotive, aerospace, and electronics industries.

High Precision: The die-casting process can create complex designs with precise dimensions, ensuring the parts fit perfectly.

Cost Effective: Volume production capabilities and shorter cycle times make aluminum die casting a cost effective manufacturing method.

Versatility: Aluminum alloys can be customized to specific requirements, enabling parts to be produced with the required mechanical properties, corrosion resistance, and thermal conductivity.

- Application:

Aluminum die castings have applications in various industries:

Automotive: engine components, transmissions and structural parts

Electronics: Housings for smart devices, computer components, and radiators

Electrical appliances: refrigerators, air conditioners, washing machine parts

Medical: Equipment production, medical devices, surgical instruments

Industrial: Optical equipment, X-ray machines, and production equipment

Other industries: musical instruments, sports equipment, etc.

Key Takeaway: Aluminum die casting is an efficient manufacturing process that produces high-quality metal parts with precise dimensions. Its lightweight and versatility make it suitable for various industries, providing cost-effectiveness and superior performance.

Types of Aluminum Alloy Die Casting

Aluminum alloy die casting is an excellent manufacturing process that offers versatility and durability. China’s leading manufacturer, Mindwell Casting, specializes in producing high-quality aluminum die casting products using various types of aluminum alloys. Let’s explore the different types of aluminum alloy die casting:

- ADC12: This is one of the most commonly used aluminum alloys in die casting. It offers good fluidity, excellent corrosion resistance, and high dimensional stability. ADC12 is widely used in the automotive industry for parts like engine components, transmission cases, and wheel rims.

- A380: A380 is another popular aluminum alloy known for its superior strength and excellent heat resistance. It is commonly used in electrical enclosures, housings, and other applications that require high strength and good thermal stability.

- A356: A356 is an aluminum-silicon alloy that offers excellent castability and high strength. It is commonly used in manufacturing structural components, aerospace parts, and complex designs that require precise dimensions.

- AlSi10Mg: This aluminum alloy is known for its exceptional strength-to-weight ratio, making it ideal for lightweight applications. It is commonly used in the production of optical devices, electronic components, and parts for the medical device industry.

- ADC6: ADC6 is an aluminum-zinc-magnesium alloy known for its good mechanical properties and high conductivity. It finds applications in heat sinks, electrical connectors, and other components requiring good thermal conductivity.

- A413: A413 is an aluminum-silicon alloy that offers excellent fluidity and high corrosion resistance. It is widely used in manufacturing complex-shaped components, like those found in the telecommunications industry.

Mindwell Casting, as a top manufacturer, understands the diverse needs of various industries and provides custom aluminum die casting solutions with these different aluminum alloy options available. They use state-of-the-art technology and advanced equipment to ensure precise dimensions, good surface finish, and total customer satisfaction.

key Takeaway: Aluminum alloy die casting offers a wide range of options, including ADC12, A380, A356, AlSi10Mg, ADC6, and A413, each catering to specific industry needs. Mindwell Casting excels in providing high-quality die casting products using these aluminum alloys to meet custom requirements.

Production facilities of China’s leading aluminum die-casting manufacturer

China’s leading aluminum die-casting manufacturer has an impressive production facility that combines state-of-the-art technology with meticulous attention to detail. Focusing on high-quality manufacturing, the facility is capable of producing a wide range of aluminum die-cast products to meet the needs of various industries.

- Advanced mechanical equipment:

The production facility is equipped with state-of-the-art die-casting machines that utilize high-pressure technology to manufacture sophisticated aluminum castings. These machines are designed to ensure consistent results and exceptional quality in every product manufactured. Cutting-edge technology is used to monitor the entire casting process, ensuring precise dimensions and excellent surface finish of the final product.

- Customization capabilities:

One of the facility’s key strengths is the ability to provide custom aluminum die-casting solutions. With a skilled team of engineers and technicians, manufacturers can work closely with customers to design and produce custom die-cast parts that meet their specific requirements. Whether it is small batch production or large-scale projects, the facility can meet diverse customization needs.

- Specialization in thin-walled complex castings:

The production facility specializes in the production of thin-walled, complex castings frequently required in industries such as automotive, aerospace and electronics. Through the expertise of skilled employees and the utilization of advanced machinery, the manufacturer is able to produce aluminum castings with precise dimensions and intricate designs, ensuring the highest levels of quality and functionality.

- Post-processing workshop:

To further improve the quality and performance of aluminum die-casting products, manufacturers have dedicated post-processing workshops. The workshop is equipped with advanced process equipment and technology such as trimming, deburring, surface treatment, and quality testing. The attention to detail in these post-processing processes helps ensure that each product meets the strict quality standards set by the manufacturer.

- Commitment to total customer satisfaction:

At this leading aluminum die-casting manufacturer, customer satisfaction is of the utmost importance. Every step of the production process is closely monitored and quality checked to ensure that the final product not only meets but exceeds customer expectations. A commitment to excellent quality combined with efficient production processes makes them the first choice for many companies requiring high-quality aluminum die-cast products.

Key takeaways: China’s leading aluminum die casting manufacturer has production facilities equipped with advanced machinery, offers customization capabilities, specializes in the production of thin-walled complex castings, has dedicated post-processing workshops, and is dedicated to

Main Die Casting Alloy Used

When it comes to high-quality aluminum pressure die casting products, the choice of die casting alloy plays a crucial role. China’s leading manufacturer, Mindwell Casting, understands the importance of selecting the right alloy to ensure the best outcome for their products. Here, we explore the main die casting alloys used by Mindwell Casting in their manufacturing process:

- Aluminum Alloy ADC12 (A383):

ADC12 is a commonly used aluminum alloy that offers excellent casting properties, good mechanical strength, and high dimensional stability.

This alloy is highly versatile, making it suitable for various industry applications, including automotive, electronics, and consumer goods.

ADC12 exhibits good fluidity during the casting process, allowing for intricate and complex designs with precise dimensions.

- Aluminum Alloy A380:

A380 is another popular choice for die casting due to its excellent fluidity, corrosion resistance, and thermal properties.

This alloy is commonly used in the manufacturing of parts for the automotive, aerospace, and electrical industries.

A380 offers good machinability and can achieve a high-quality surface finish, making it ideal for products that require a polished appearance.

- Aluminum Alloy ADC10 (A360):

ADC10 is a lightweight aluminum alloy that provides exceptional strength-to-weight ratio, making it suitable for applications where weight reduction is crucial.

This alloy offers good corrosion resistance and thermal conductivity, making it ideal for heat dissipation components.

ADC10 is commonly used in the production of electronic devices, optical devices, and medical equipment.

- Aluminum Alloy ADC6 (A413):

ADC6 is a versatile alloy that possesses excellent castability and is known for its ability to produce thin-walled and complex castings.

This alloy offers good mechanical properties and maintains its strength even at high temperatures.

ADC6 is commonly used in the manufacturing of automotive components, household appliances, and musical instruments.

By carefully selecting the appropriate die casting alloy for each specific application, Mindwell Casting ensures that their products meet the highest standards in terms of strength, durability, and overall quality. Their commitment to using high-quality die casting alloys contributes to the success and total customer satisfaction they achieve in various industries.

key Takeaway: Mindwell Casting, China’s leading manufacturer, utilizes a range of die casting alloys including ADC12, A380, ADC10, and ADC6, ensuring the production of high-quality and durable aluminum pressure die casting products across

Customized aluminum die-casting products

Custom aluminum die-cast products are one of the specialty products offered by China’s leading manufacturers. With state-of-the-art manufacturing plants and production facilities, they are able to produce high-quality custom die-cast parts for various industries. Here are some key features and benefits of its custom aluminum die-cast products:

- Precise Dimensions: Customized aluminum die-cast products are manufactured using advanced die-casting technology, ensuring precise dimensions and tight tolerances. This is essential to achieve the required fit and functionality in different applications.

- Good surface finish: Manufacturers attach great importance to the surface finish of their custom aluminum die-cast products. Through a careful post-processing process, they can achieve a smooth, flawless surface ready for any desired coating or finish.

- Thin-walled complex castings: Their expertise in aluminum die casting enables them to produce thin-walled complex castings with intricate designs. This feature is particularly valuable for industries that require lightweight, durable components.

- Multiple options: Manufacturers offer a variety of aluminum alloys to choose from for custom die casting. This ensures customers can select the most appropriate alloy based on the specific requirements of their application.

- Overall Customer Satisfaction: The company prioritizes customer satisfaction and aims to deliver custom aluminum die-cast products that meet or exceed customer expectations. They work closely with customers throughout the manufacturing process to ensure all specifications and quality standards are met.

Mindwell Casting is the manufacturer’s primary supplier of die-cast parts. Their partnership enables the production of high-quality custom aluminum die-cast products that meet the highest industry standards.

Key Takeaway:China’s leading manufacturer specializes in custom aluminum die-cast products that feature precise dimensions, excellent surface finish, thin-walled complex castings, multiple alloy options, and customer satisfaction. They partner with Mindwell Casting to provide high-quality products to various industries.

High-pressure die-casting process

The high-pressure die-casting process is a widely used method in the manufacturing industry, particularly for producing high-quality aluminum die-cast products. The process involves injecting molten aluminum under high pressure into a steel mold, also called a die. Molds are designed to create the desired shapes and features of the final product. Here, we’ll explore the steps involved in the high-pressure die casting process and why it’s favored by manufacturers.

- Mold preparation:

Before the casting process starts, the mold needs to be prepared. This includes cleaning, lubricating and preheating the mold to ensure a smooth flow of molten aluminum and prevent any potential defects. The mold is also coated with release agent to facilitate removal of the solidified casting.

- Liquid aluminum injection:

Once the mold is ready, molten aluminum is poured into the mold cavity under high pressure. The metal fills the entire cavity, shaping the mold and forming the desired product. High-pressure injection ensures that molten aluminum reaches all intricate details and corners of the mold, allowing for precise dimensions and intricate designs.

- Solidification and cooling:

After injection, the molten aluminum solidifies quickly inside the mold thanks to a cooling system embedded within the mold. This ensures that the product retains its shape after ejection from the mold. The cooling process is carefully controlled to achieve desired metallurgical properties such as strength and hardness.

- Ejection of castings:

Once the casting has solidified and cooled, it is ejected from the mold using an ejector pin or mechanism. The castings are then separated from excess material such as gates and runners and recycled for future use. The ejected castings undergo further post-processing to improve their surface finish and remove any remaining defects.

Key Takeaway: The high pressure die casting process involves injecting molten aluminum into a steel mold under high pressure to create precise and complex aluminum castings. This process ensures excellent dimensional accuracy, intricate designs, and good surface finish.

Production plant and equipment production

When it comes to producing high-quality aluminum die-cast products, having a state-of-the-art manufacturing facility and state-of-the-art equipment is crucial. Leading Chinese manufacturer Mindwell Casting understands the importance of investing in advanced facilities and technology to ensure the best possible results.

State-of-the-art manufacturing facility:

- Mindwell Casting has a modern manufacturing plant equipped with state-of-the-art machinery. The facility has been designed with efficiency and precision in mind, allowing for a seamless production process.

- The factory layout is optimized to minimize production time, reduce errors and enhance workflow. This ensures a high level of simplification of the manufacturing process, resulting in a quality product.

- The facility focuses on quality control and is equipped with the latest inspection and testing technology. These include state-of-the-art X-ray machines and other advanced tools to ensure the highest precision and accuracy for each product.

Advanced equipment production:

- Mindwell Casting is proud of its commitment to staying at the forefront of technological advancements in the industry. The company continuously updates equipment to meet the changing needs of various industries.

- Mindwell Casting uses manufacturing equipment specifically designed for aluminum die casting. These machines are able to produce thin-walled, complex castings with precise dimensions and good surface finish.

- Mindwell Casting has a series of equipment such as high-pressure die-casting machines, gravity die-casting machines, and post-processing workshops, which can meet the needs of different customers.

Investment in equipment production and continuous improvement of manufacturing processes are the main reasons why Mindwell Casting has a reputation as a top manufacturer. The company focuses on overall customer satisfaction and has always been committed to providing excellent aluminum die-casting products for various industries such as automobiles, electronics, and medical equipment.

Key Takeaways: Mindwell Casting’s state-of-the-art manufacturing plants and production contributions from advanced equipment

Quality control and post-treatment workshop

When manufacturing high-quality aluminum die-cast products, it is critical to maintain strict quality control standards and employ effective post-processing processes. China’s leading aluminum die-casting manufacturer understands the importance of both aspects and ensures its products meet the highest standards.

- Quality control measures

To provide top-notch products, manufacturers implement comprehensive quality control measures to monitor every step of the production process. These include:

Manufacturing Factory Inspection: Each die-cast part undergoes a meticulous inspection process to check its size, surface finish, and structural integrity. This ensures that only perfect products make it to the next stage.

X-ray machines for defect detection: Manufacturers utilize advanced X-ray technology to detect the smallest flaws or inconsistencies in final castings. This ensures the production of highly precise and reliable products.

Strict adherence to international standards: Manufacturers adhere to strict quality control standards such as ISO

9001, maintaining consistency and ensuring the highest quality level throughout the entire production process.

- Post-treatment workshop

After the die cast is formed, it undergoes a post-processing process to improve its performance, durability and visual appeal. The manufacturer’s dedicated post-processing shop provides a range of services including:

Surface treatment: The workshop uses a variety of techniques including polishing, sandblasting, powder coating, etc. to achieve the desired surface texture and appearance. This enhances the beauty of the finished product.

Machining and Assembly: In addition to the casting process, manufacturers also offer machining services to refine dimensions and create precise features. Assembly services are also available to integrate multiple components, ensuring the final product is ready for use.

Testing and inspection: The post-processing workshop conducts strict testing and inspection procedures to ensure that the finished products meet all quality requirements. This includes functional tests, dimensional inspections and performance evaluations.

Key Takeaways: By prioritizing thorough quality control and efficient post-processing processes, leading aluminum die casting manufacturers ensure the production of high-quality products that meet the stringent requirements of various industries.

Thin-walled and complex castings in various industries

One of the most impressive achievements in aluminum die casting is the production of thin-walled, complex castings. These complex components are in high demand across various industries due to their unique properties and applications.

- Precision and Dimensional Accuracy:

Thin-walled complex castings require extremely high precision and dimensional precision. Mindwell Casting, China’s leading manufacturer of aluminum die castings, specializes in the production of these extremely precise and complex parts. Their state-of-the-art equipment and advanced production techniques ensure that each casting meets specified tolerances and exact dimensions.

- Strength and durability:

Despite the thin walls, these castings are designed to be very strong and durable. The use of high-quality aluminum alloys ensures that these components can withstand harsh working conditions without compromising strength or performance. This makes them ideal for applications in industries such as automotive, aerospace, electronics and more.

- Lightweight and cost-effective:

Thin-walled complex castings have the advantage of being lightweight while maintaining structural integrity. This makes them an excellent choice for industries like automotive and aerospace where weight reduction is critical. In addition, its efficient production process allows for cost-effective manufacturing, making it a practical solution for a variety of applications.

- Versatility and customization:

The versatility of thin-walled complex castings enables them to be customized to specific industry needs. Whether designing complex shapes, integrating additional features, or meeting exacting specifications, JC Casting has the expertise and capabilities to deliver custom solutions. Their skilled engineers and advanced die-casting technology ensure the production of castings that meet the unique requirements of every industry and application.

Key Takeaways: Mindwell Casting, China’s leading aluminum die casting manufacturer, produces thin-walled, complex castings with superior precision, strength and durability. These lightweight components are customized for a variety of industries and applications, providing cost-effective solutions for manufacturers in automotive, aerospace, electronics and more.

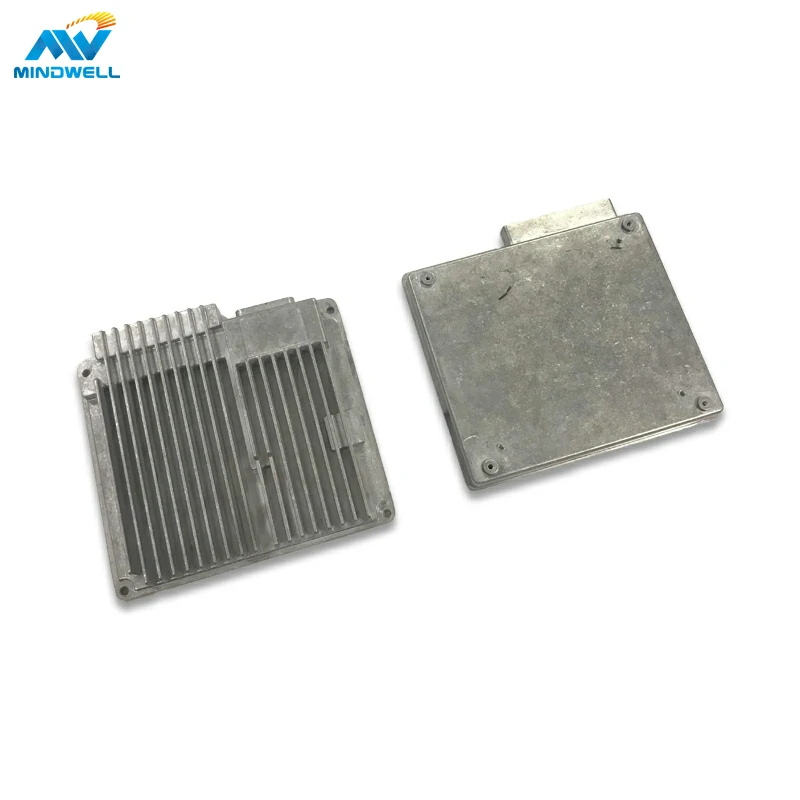

Main products offered by the manufacturer

When it comes to high-quality aluminum die-cast products, China’s leading manufacturers offer an impressive range of options. With state-of-the-art manufacturing facilities and a commitment to excellence, they have become the first choice for businesses across a wide range of industries. Let’s take a deeper look at some of their main products:

- Die-casting parts for various industries: This manufacturer specializes in producing die-casting parts for various industries, including automotive, aerospace, electronics, medical devices, etc. Their expertise allows them to manufacture precision parts that meet the specific requirements of each industry.

- Custom Aluminum Die Cast Products: Whether you require intricate shapes, intricate designs, or specific sizes, manufacturers are skilled in producing custom aluminum die cast products. Their highly skilled team can turn your ideas into reality, providing tailor-made solutions for your unique needs.

- High-pressure die-casting parts: High-pressure die-casting parts are known for their precise dimensions and excellent surface finish. The manufacturer’s cutting-edge equipment and extensive experience enable them to produce high-pressure die-cast parts of exceptional quality and performance.

- Thin-walled complex castings: This manufacturer relies on advanced technology and professional knowledge to specialize in the production of thin-walled complex castings. These types of castings require complex designs and precise dimensions, and manufacturers ensure that they meet the highest quality standards.

- Optics: If you need optics, such as lenses or optical housings, manufacturers can provide you with top-notch aluminum die-cast solutions. Their attention to detail and dedication to quality ensures that they produce optical equipment with the highest optical clarity and precision.

- Electronic devices and components: From complex electronic housings to connectors and heat sinks, the manufacturer’s aluminum die-cast products are widely used in the electronics industry. Their expertise in casting precision durable components makes them a reliable manufacturing partner for electronic equipment.

- Medical Device Components: Manufacturers’ commitment to excellence extends to the medical industry. They produce high-quality aluminum die-cast components for medical devices, ensuring they meet the most stringent quality standards and regulatory compliance.

- Musical instrument parts: Manufacturers also cater to the needs of the musical instrument industry. Whether it’s a brass, percussion or woodwind component, they can provide high-performance and durable die-cast solutions for your instruments.

These are just some examples of the wide range of high-quality aluminum die-casting products available from China’s leading manufacturers.

Manufacturing solutions for medical device industry

The medical device industry requires high-quality manufacturing solutions to ensure safe and reliable products are produced. Mindwell Casting, China’s leading manufacturer, offers a range of best-in-class aluminum die-casting products specifically designed for the medical device industry.

- Precision and Dimensional Accuracy Mindwell Casting understands the importance of accurate dimensions in medical equipment. They use advanced aluminum die-casting technology to produce parts with superior precision that meet the industry’s stringent requirements. Their manufacturing processes are closely monitored to ensure the highest levels of dimensional integrity.

- Excellent surface finish

Medical equipment requires a pristine surface finish to ensure ease of cleaning and minimize the risk of contamination. Mindwell casting excels at providing a good surface finish to parts, reducing the potential for bacterial growth and ensuring the safety and hygiene of the final product.

- Thin-walled complex castings

Some medical devices, such as implants and surgical instruments, typically have complex designs and thin-walled structures. Mindwell casting is capable of handling the complexity of these components. Their expertise in aluminum die-casting enables the production of thin-walled complex castings with precise detail and structural integrity.

- Customization according to specific needs

The medical device industry meets the needs of a wide range of professional applications. Mindwell casting offers extensive customizability, allowing manufacturers to customize their products according to specific requirements. Whether designing custom die-cast parts for diagnostic equipment or developing unique components for therapeutic devices, Mindwell Casting offers flexible solutions to meet diverse needs.

- Adhere to regulatory standards

Regulatory compliance is vital in the medical device industry. Mindwell Casting adheres to strict quality standards and regulations to ensure its aluminum die-casting products meet or exceed international requirements. With a deep understanding of industry guidelines, they consistently provide compliant, reliable and safe products for medical applications.

Key Takeaways: Mindwell casting is a leading manufacturer in China that specializes in manufacturing high-quality aluminum die-cast products for the medical device industry. They offer high accuracy, superior surface finish, customizability and compliance with regulatory standards to meet the specific needs of manufacturers in the healthcare industry.

Electronic equipment die casting production

Electronic devices have become an integral part of our daily lives, and the demand for high-quality die-cast parts specifically designed for these devices is increasing. Mindwell Casting, a leading manufacturer in China, has made its mark in the industry by producing state-of-the-art aluminum die-casting parts for electronic devices.

- Efficient manufacturing factory:

Mindwell Casting has a state-of-the-art manufacturing facility equipped with advanced technology and machinery. Their production facilities are equipped with state-of-the-art high-pressure die-casting machines to efficiently and accurately produce die-cast parts for electronic devices.

- Professional knowledge in various industries:

With years of experience, Mindwell Casting understands the unique requirements of different industries. They have a subsidiary dedicated to servicing the electronic equipment industry, ensuring that the die-cast parts they produce meet the highest quality and functionality standards.

- Customized exact size:

One of the most compelling aspects of Mindwell Casting’s production is their ability to manufacture custom die-cast parts with precise dimensions. By utilizing advanced machinery and specialized craftsmanship, they can meet the specific needs of electronic device manufacturers, ensuring a perfect fit and seamless integration.

- Excellent surface finish:

Mindwell Casting recognizes the importance of aesthetics in electronic devices. Their die-cast parts are known for their excellent surface finish, giving the final product a visually appealing appearance. This level of quality is achieved through meticulous attention to detail and strict quality control measures.

- Compatibility with various aluminum alloys:

In order to meet the diverse requirements of electronic equipment, Mindwell Casting uses various types of aluminum alloy die castings. Whether low-volume or high-volume production, their manufacturing capabilities allow them to use different aluminum alloys, ensuring compatibility and optimal performance.

- Commitment to total customer satisfaction:

Mindwell Casting prioritizes customer satisfaction. They work closely with customers throughout the production process to ensure clear communication and understanding of requirements. This collaborative approach helps them deliver die-cast parts that meet or exceed their customers’ expectations.

Key Takeaways: Mindwell Casting is a top manufacturer in China that specializes in high-quality aluminum die-casting parts for electronic devices. With their advanced manufacturing facilities, industry expertise, custom sizes, superior surface finish, compatibility with different alloys, and commitment to total customer satisfaction, they are a leading manufacturer of reliable, precision die-cast parts tailored for the electronic equipment industry.

Optical and precision measurements in aluminum die casting

In the field of aluminum die casting, optics and precision measurement play a crucial role in ensuring the production of high-quality products. As a leading aluminum die-casting manufacturer in China, we understand the importance of these factors and prioritize them in our manufacturing process.

- The importance of optics in aluminum die casting:

When producing state-of-the-art aluminum die-cast products, optical equipment is utilized for quality control and inspection. These devices, such as X-ray machines, help inspect the internal structure of the casting to ensure there are no defects or imperfections that could compromise the integrity of the final product. By employing advanced optical inspection technology, we can detect even the smallest anomalies and guarantee the production of perfect castings.

- Precision measurement ensures excellent quality:

Accurate and precise measurements are fundamental to achieving the required specifications and dimensions in aluminum die casting. Our manufacturing facilities are equipped with state-of-the-art measurement equipment, allowing us to consistently produce dimensionally accurate components. From complex geometries to thin-walled castings, our production facilities ensure that every detail is met to the exact specifications required by our customers.

- Advanced equipment to achieve the best results:

In order to achieve the highest levels of quality, we rely on the most advanced equipment in the industry. Our machines are specifically designed for high-pressure die casting, allowing us to produce parts with excellent surface finish and precise dimensional accuracy. With the support of these cutting-edge machinery, we are able to manufacture complex precision castings with ease.

- Continuous improvement to achieve overall customer satisfaction:

At our Aluminum Die Cast Manufacturing Company, customer satisfaction is our top priority. We continuously strive to improve our production processes, implement stringent quality control measures and employ innovative technologies to enhance the optical and precision measurement aspects of our operations. By adhering to strict quality standards, we ensure that only the highest quality castings leave our production facilities, meeting or exceeding our customers’ expectations.

Key Takeaway: Optical and precision measurements are integral to producing high-quality aluminum die-cast products. With state-of-the-art equipment, strict quality control, and a commitment to customer satisfaction, we ensure every casting meets the highest standards of precision and perfection.

Musical instruments and aluminum die-casting parts

Speaking of musical instruments, the role of aluminum die-casting cannot be ignored. This manufacturing process plays a crucial role in producing high-quality components that are essential in the construction of all types of musical instruments. From brass instruments such as trumpets and trombones to woodwind instruments such as saxophones and clarinets, aluminum die castings are used in a variety of ways to enhance the performance and durability of these instruments.

- The importance of aluminum die castings in musical instruments

Aluminum die castings are widely favored in musical instrument production due to their exceptional properties. The process allows for precise dimensions, thin-walled complex castings, and excellent surface finishes, which are key factors in creating instruments that deliver superior sound quality and performance. The use of aluminum die-casting also reduces the overall weight of the instrument, making it easier to play for long periods of time.

- Components produced by aluminum die castings

Many components in the instrument are manufactured using aluminum die castings. These include the body of the instrument, key mechanism, sound holes, finger rests, and other complex parts that contribute to the functionality and beauty of the instrument. Precise tolerances achieved through aluminum die-casting ensure these components fit together seamlessly, providing musicians with an exceptional playing experience.

- Advantages of aluminum die castings in musical instruments

STRENGTH AND DURABILITY: Aluminum die-casting produces components with exceptional strength and durability, allowing the instrument to withstand the demands of regular playing and frequent shipping.

Reduced Weight: By utilizing lightweight aluminum alloy, die-casting helps reduce the overall weight of the instrument without sacrificing strength or performance.

Vibrational Properties: Aluminum’s unique vibrational properties contribute to the resonance and tone quality of the instrument, thereby enhancing its overall sound.

- Customization and design flexibility

Aluminum die casting offers a high degree of design flexibility, allowing the creation of intricate shapes not easily achieved through other manufacturing processes. This allows instrument manufacturers to create instruments with unique designs and optimize their performance for specific musical styles or genres.

- High quality die castings from China’s leading manufacturer

Mindwell Casting, a leading Chinese manufacturer, stands out as the first choice when it comes to sourcing high-quality aluminum die-cast products for musical instruments. With state-of-the-art manufacturing facilities and die-casting expertise, Mindwell Casting offers a variety of custom die-cast products to meet the unique needs of the musical instrument industry. Their commitment to all their customers

X-Ray Machine and Aluminum Die Casting

Aluminum die-casting is a widely used manufacturing process that produces high-quality parts for a variety of industries. One of the industries in which aluminum die-casting plays a key role is the production of X-ray machines. Let’s delve deeper into the importance of aluminum die casting in X-ray machine manufacturing and explore some of the top products in this field.

- Aluminum Housing: X-ray machines require strong housing to protect the delicate internal components. Aluminum die-casting has the advantage of producing a strong, lightweight housing that can withstand the rigors of everyday use. These housings ensure safe operation and protection of the internal components of the X-ray machine.

- X-ray Tube: The X-ray tube is the heart of any X-ray machine and is responsible for generating X-rays. With aluminum die casting, complex and precise components such as anodes, cathodes and other tube parts can be manufactured with exceptional accuracy and dimensional stability. This ensures reliable performance and service life of the x-ray tube.

- Heatsink: X-ray machines generate large amounts of heat, which needs to be dissipated efficiently to ensure optimal performance and prevent overheating. Aluminum die-casting offers a cost-effective solution for manufacturing heat sinks with excellent thermal conductivity. These heat sinks effectively dissipate heat, allowing the X-ray machine to operate at its optimal performance.

- Mounting Brackets: To ensure proper alignment and stability of the components inside the X-ray machine, mounting brackets are critical. Aluminum die-casting enables the production of custom-designed mounting brackets that are strong, durable and precisely meet the machine’s requirements. These brackets provide stability, reducing the risk of critical components being misaligned or damaged.

- Control Panel: The X-ray machine contains a control panel that allows the operator to adjust settings and monitor the machine’s performance. Aluminum die-casting helps produce control panel assemblies that are not only beautiful but also durable and resistant to wear and tear. These components ensure smooth operation and a user-friendly interface.

- Wiring Harness: X-ray machines rely on complex wiring systems to connect the various components and ensure proper operation. Aluminum die casting enables the production of wire harness assemblies that are lightweight yet strong enough to withstand operating stresses. These components help increase the reliability and service life of your X-ray machine.

Key Takeaways: Aluminum die castings play a vital role in the manufacturing of X-ray machines, providing durable housings, precision components, and efficient aluminum die casting performance.

Innovative Solutions for the Automotive Industry

The automotive industry requires high-quality, reliable and innovative products to keep up with rapidly evolving technological advances. As a top manufacturer in aluminum die casting, our company is proud to offer a wide range of innovative solutions designed specifically for the automotive industry. Our commitment to excellence and cutting-edge technology differentiates us from other manufacturers in the market.

- Lightweight aluminum die castings:

Our main product line focuses on lightweight aluminum die-casting parts. These parts play a vital role in improving fuel efficiency and overall vehicle performance.

By using advanced casting technology and high-pressure die-casting machines, we ensure that our aluminum parts have precise dimensions, excellent surface finishes, and are easily integrated into complex automotive designs.

- Customized solutions for car manufacturers:

Understanding the diverse needs of the automotive industry, we offer custom aluminum die-casting solutions tailored to the specific requirements of our customers.

Whether it’s engine components, drivetrains, chassis components or interior and exterior accessories, our manufacturing facilities are capable of producing a wide range of custom die-cast products of exceptional quality.

- Advanced manufacturing facilities:

We are equipped with state-of-the-art production facilities, including modern subsidiaries and post-processing workshops, capable of meeting the stringent requirements of the automotive industry.

Our highly skilled technicians and engineers utilize cutting-edge equipment to deliver high-quality aluminum die-cast parts that meet industry standards and customer expectations.

4.Strict quality control measures:

Quality is our top priority at our manufacturing company. We adhere to strict quality control measures throughout our production process to ensure complete customer satisfaction.

Our products are thoroughly inspected, including X-ray testing and quality assessment, to ensure they meet the highest standards of performance, durability and functionality.

Key Takeaways: Our leading manufacturing company specializes in providing innovative and high-quality aluminum die-casting solutions to the automotive industry. With advanced manufacturing facilities, customization options and stringent quality control measures, we are dedicated to meeting the unique needs of automakers.

Small batch and large batch die casting orders

We provide OEM services, whether you are customizing small batches or large batches, we are capable of producing them for you.

Ensure full customer satisfaction

We will send you a sample and ensure your complete satisfaction before starting mass production.

Business operations of leading manufacturers

China’s leading manufacturer of high-quality aluminum die-casting products with mature business and wide range of business. Here, we’ll take a deep dive into every aspect of their business operations to give you a complete understanding of their capabilities and strengths.

- Manufacturing plants and production facilities:

The manufacturer has a state-of-the-art manufacturing facility that is equipped with advanced technology and machinery.

With efficient production facilities, they are capable of handling both small and large scale production.

Their commitment to continuous improvement ensures process simplification and productivity optimization.

- Applications in various industries:

The manufacturer serves a wide range of industries including automotive, aerospace, electronics, medical devices, musical instruments and more.

By diversifying their customer base, they have gained experience and expertise in meeting the unique requirements of each industry.

- Top manufacturer status:

With an impeccable track record and commitment to excellence, they have earned their reputation as one of the industry’s top manufacturers.

Their dedication to quality and customer satisfaction has enabled them to build strong relationships with customers around the world.

- Customization and product range:

The manufacturer specializes in custom aluminum die casting, providing custom solutions to meet individual customer needs.

They have a wide range of die-cast parts including thin-walled complex castings, metal parts for electronic devices, optical devices and more.

Their ability to produce custom products with precise dimensions and superior surface finish sets them apart.

- Quality assurance:

In order to ensure the highest quality standards, the manufacturer follows strict quality control measures throughout the production process.

X-ray machines and other advanced inspection equipment are used to detect any defects or anomalies to ensure that the product is flawless.

- Continuous innovation:

The manufacturer values innovation and regularly invests in research and development to maintain its market leadership.

By keeping abreast of the latest advances in technology and materials, they continue to provide cutting-edge solutions to their customers.

Key Takeaways: China’s leading manufacturer of high-quality aluminum die-casting products has a well-established business and robust operations.

Aluminum Die Casting Machine Supplier – Mindwell Casting

Mindwell Casting is an industry-leading supplier of high-quality aluminum die casting machine consumables. With their state-of-the-art manufacturing facilities, they have earned a reputation for delivering best-in-class products to various industries.

- Broad product range:

Mindwell Casting offers a diverse range of aluminum die casting products to meet the needs of different industries. From medical devices to electronics, and from musical instruments to optical equipment, their product catalog is extensive. Whether you need small or high-volume production, Mindwell Casting can meet your requirements.

- Excellent die-casting technology:

Mindwell Casting uses high-pressure die-casting to ensure manufactured products have precise dimensions and good surface finish. The technology enables the production of thin-walled, complex castings, which is critical for industries that require intricate designs.

- Unparalleled expertise:

With years of experience and expertise in the die casting industry, Mindwell Casting has gained the knowledge needed to produce quality products. Their team of professionals understands the nuances of different aluminum alloys and selects the most appropriate alloy for each specific project. This expertise ensures the production of strong and durable die-cast parts.

4.Advanced production facilities:

Mindwell Casting has a state-of-the-art production facility equipped with state-of-the-art die-casting machines and equipment, allowing them to deliver products with superior accuracy and precision. They focus on meeting the highest quality standards, prioritizing the use of technologically advanced equipment to ensure the best results for their customers.

- Commitment to customer satisfaction:

The primary goal of Mindwell Casting is to achieve total customer satisfaction. They pay close attention to every detail of the production process, from design to post-processing shop, to ensure that each product meets or exceeds customer expectations. This commitment to quality has helped them build long-term relationships with their clients.

Key Takeaways: Mindwell Casting is a trusted aluminum die casting machine supplier known for its wide range of high-quality products, superior die casting technology, unparalleled expertise, advanced manufacturing facilities, and commitment to customer satisfaction.

Conclusion

In conclusion, choosing high-quality aluminum die-casting products from leading manufacturers is crucial for various industries. China is known for its top manufacturers, and as discussed in this blog, it’s obvious why they are the first choice for many businesses.

The following are the main contents of the blog:

- Mindwell Casting: Mindwell Casting is a reputable aluminum die casting manufacturer and its subsidiary GC Precision Mold Co., Ltd. has state-of-the-art production facilities equipped with advanced machinery and equipment to achieve efficient and precise die casting production.

- Wide product range: Mindwell Casting provides a variety of die castings for different industries, including optical devices, electronic devices, medical devices, musical instruments, etc. Their expertise lies in the production of thin-walled complex castings with precise dimensions and excellent surface finish.

- High-quality materials: The die-casting alloy used by Mindwell Casting is mainly aluminum, which has the advantages of light weight, good strength-to-weight ratio, corrosion resistance, and excellent thermal conductivity. They specialize in custom aluminum die castings, ensuring that the final product meets specific requirements.

- Cutting-edge technology: Mindwell Casting uses high-pressure die-casting technology to achieve outstanding results. The use of state-of-the-art casting machines and equipment ensures the production of high-quality, defect-free metal parts.

- Extensive quality control: Mindwell Casting maintains strict quality control measures throughout the entire manufacturing process. They use X-ray machines and have post-processing workshops to ensure every product meets strict quality standards.

- CUSTOMER SATISFACTION: Mindwell Casting is committed to providing total customer satisfaction. They prioritize customer needs, offer customization options, and guarantee the delivery of aluminum die cast products that meet or exceed expectations.

By partnering with Mindwell Casting, companies can get reliable aluminum die-cast products for a variety of applications. Their commitment to excellence, expertise, and modern manufacturing practices makes them the trusted choice for global enterprises.

Takeaway: Choosing a reputable aluminum die casting manufacturer like Mindwell Casting ensures you receive high-quality products, advanced technology, and excellent customer service, resulting in successful and reliable business operations.

In summary, China’s leading aluminum die casting manufacturer offers a wide range of high-quality products that meet the needs of various industries. Their expertise in precision engineering, advanced technology and rigorous quality control ensures the production of cast products that are durable, reliable and beautiful. From automotive parts to electronic housings and home appliances, their products cover a wide range of applications.

The manufacturer is committed to meeting international standards and prides itself on its ability to deliver superior results. Their emphasis on customization gives customers the flexibility to select products that meet their specific requirements. Whether you are a small business or a multinational company, working with this manufacturer can give you a competitive edge in the market.

FAQ

What are the main types of aluminum alloy die castings?

Aluminum die-casting is a manufacturing process that uses molds to create three-dimensional objects from metal powder or other plastic materials.

What are the main?

The main types of aluminum die-cast products are aluminum alloys, aluminum parts, aluminum castings and aluminum processing.

What die casting alloys are mainly used for die castings?

Aluminum alloy is the most common and used in die casting to produce a variety of products.

What is die casting?

Die casting is a manufacturing process used to make objects by pressing metal into a mold.

What is the difference between die castings and metal castings?

Die casting is the process of pouring molten metal into a mold to create a cavity. A die is a specially designed tool that has been used for many years to produce objects such as dies, stampings, and molds.

What are the main types of high-pressure die casting?

High-pressure die casting is a process that creates metal objects by forcing molten metal into a mold. There are three main types of high-pressure die-casting: pressure die-casting, injection die-casting, and vacuum die-casting.

What is the production process of die castings?

The production process of die casting typically begins with a design created in CAD or 3D design software. Once the design is approved, the die-casting machine is built. The machine uses pressure to press a metal mold into the desired shape.

Why is die casting better than metal casting?

Die casting is a manufacturing process where metal is formed into a desired shape by pressing it between two molds. Die casting is often preferred over metal casting because it is faster, more precise, and less expensive. Die casting also has the advantage of being able to produce complex parts with multiple functions at the same time.

What are the characteristics of custom aluminum die castings?

Die casting is a manufacturing process used to make objects by pressing a single piece of metal into a mold. It is one of the oldest manufacturing techniques and is used to make products such as auto parts, medical devices and even jewelry. Die casting is a relatively low-cost manufacturing process that can be used to create a wide range of products.